Button durability testing machine

By designing a button durability testing machine that includes a chassis, a lifting control mechanism, an electric control box, a servo motor and a transmission mechanism, the problem of low manual detection efficiency and large errors has been solved, and efficient and accurate testing of buttons has been achieved, improving detection efficiency. Efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

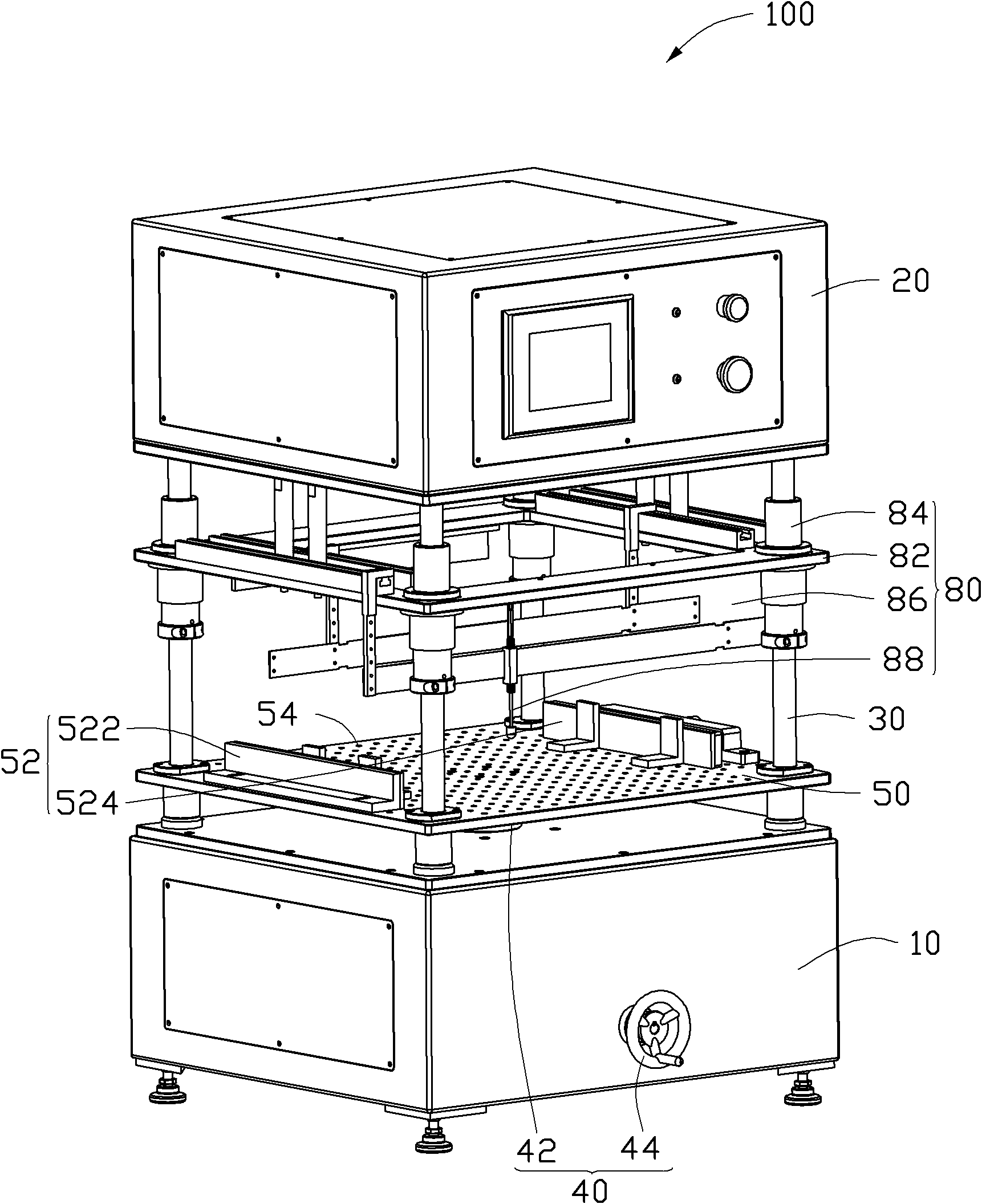

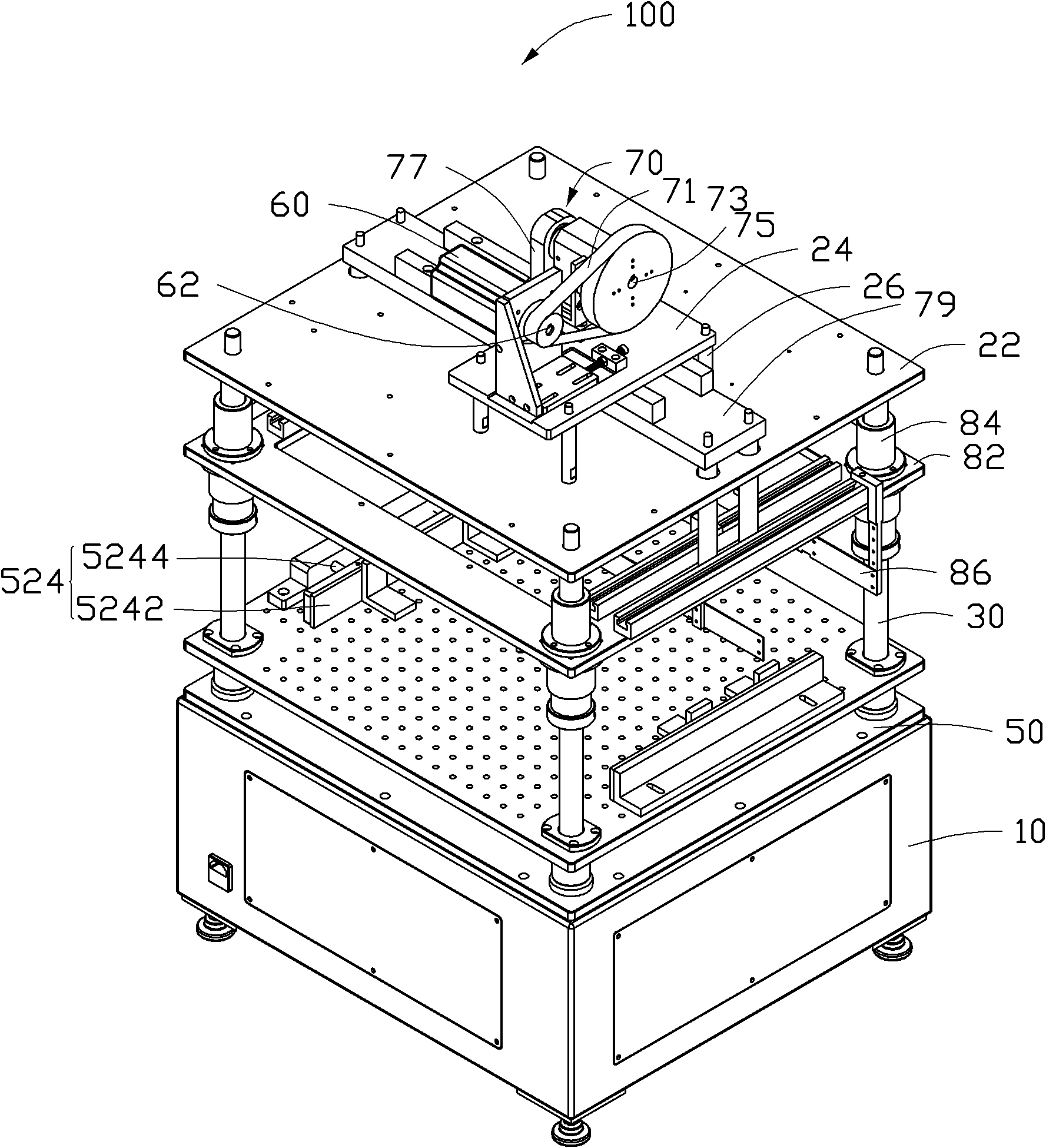

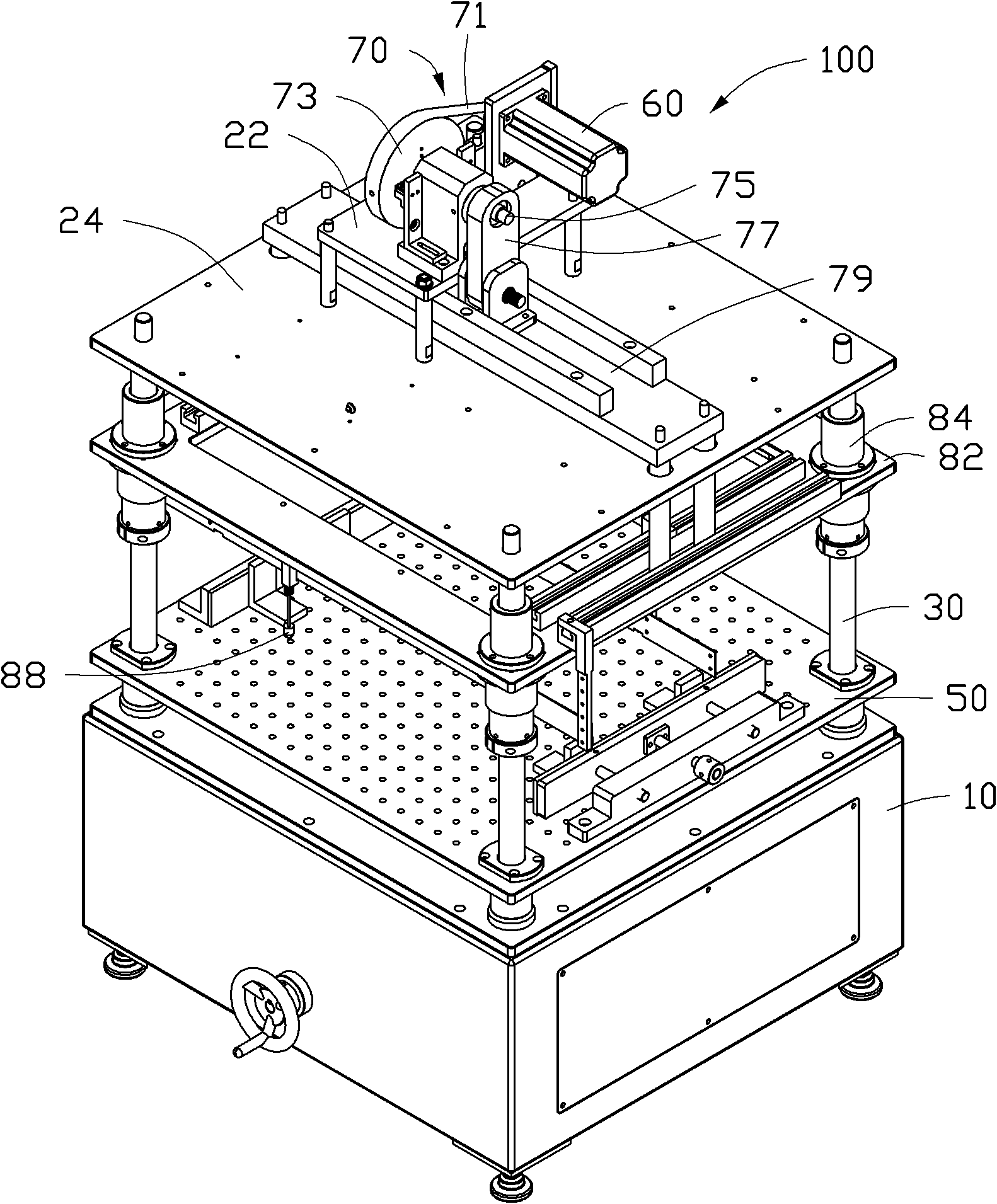

[0049] see figure 1 and figure 2 , the button durability testing machine 100 is used to test the durability of the buttons on the electronic device. In this implementation, the test of the buttons of the keyboard is taken as an example for illustration. The button durability tester 100 includes a chassis 10 , an electric control box 20 , four guide rods 30 , a lift control mechanism 40 , a workbench 50 , a servo motor 60 , a transmission mechanism 70 and a pressing assembly 80 . The guide rod 30 is fixed between the chassis 10 and the electric control box 20, the workbench 50 is movably sleeved on the guide rod 30, and the lift control mechanism 40 is installed on the chassis 10 to drive the workbench 50 up and down along the guide rod 30 Reciprocating motion, the servo motor 60 and the transmission mechanism 70 are installed in the electric control box 20, the transmission mechanism 70 is used to transmit the power output by the servo motor 60 to the pressing assembly 80, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com