Concrete durability testing device and method under synergistic action of freezing-thawing and loading

A durability test and synergistic technology, applied in the direction of measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., can solve the problems of low automation, labor and material resources, large errors, etc., to achieve suitable In application promotion, the benefit effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

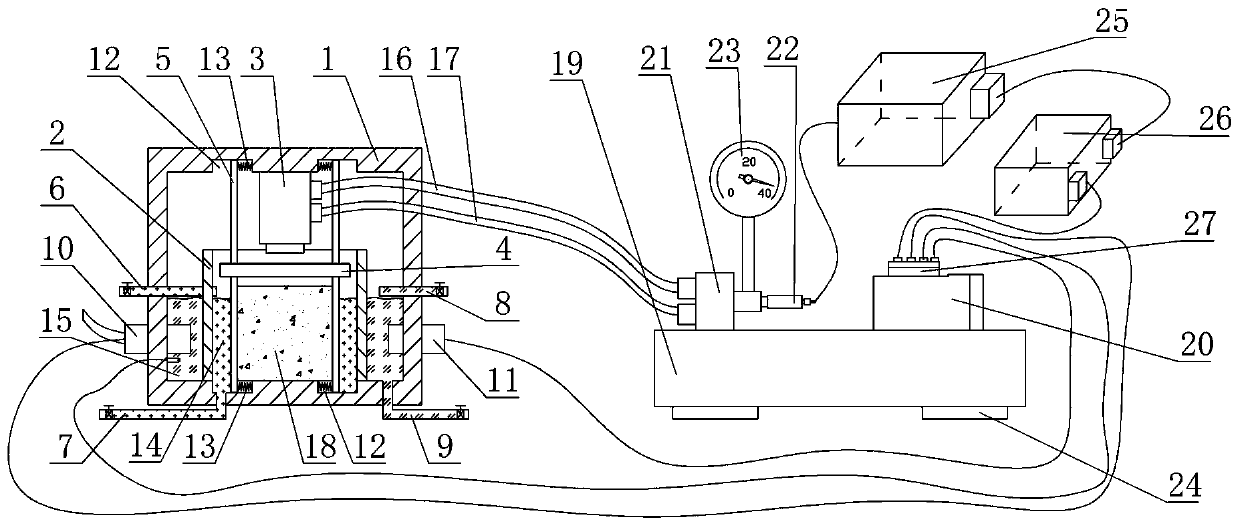

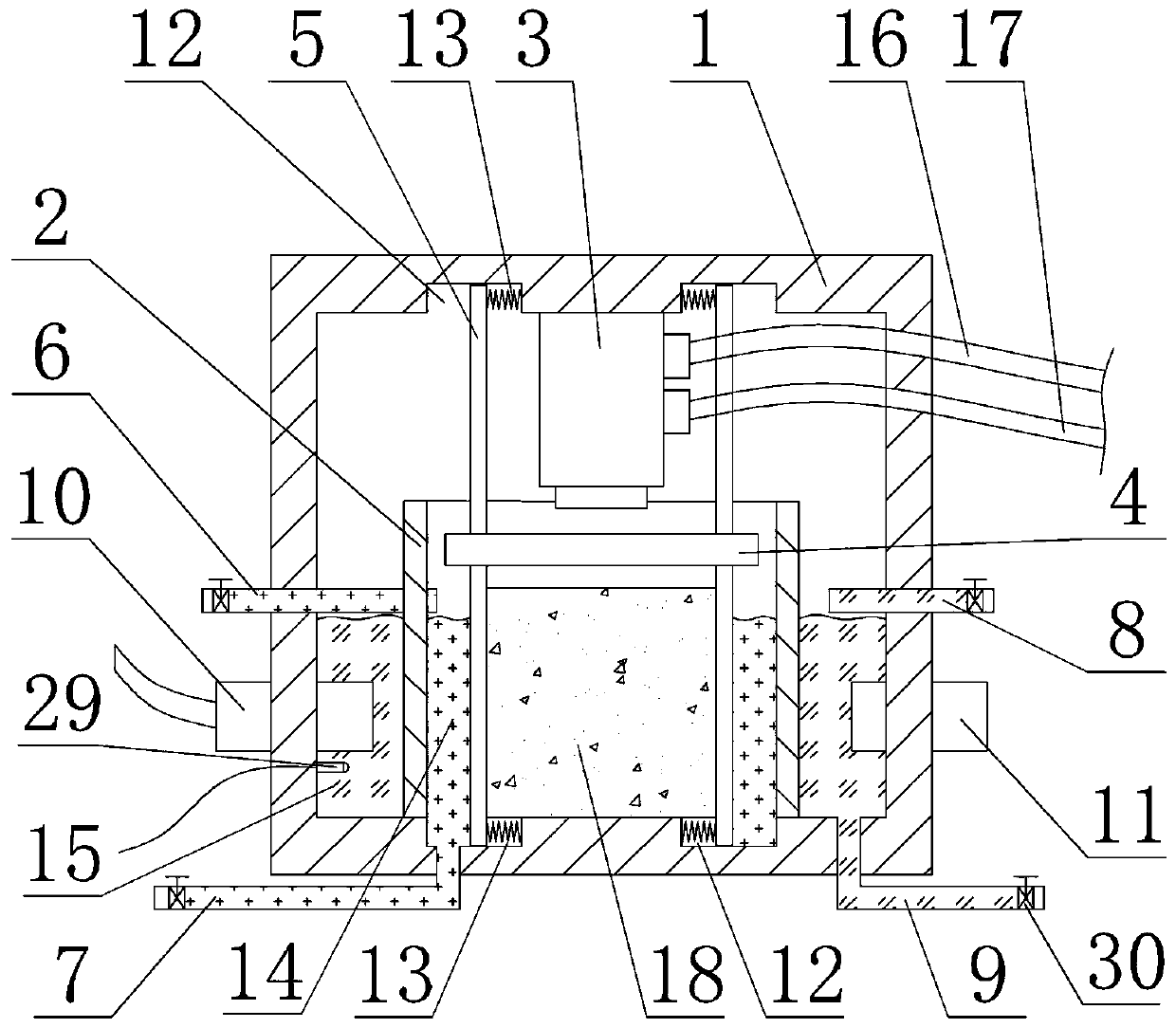

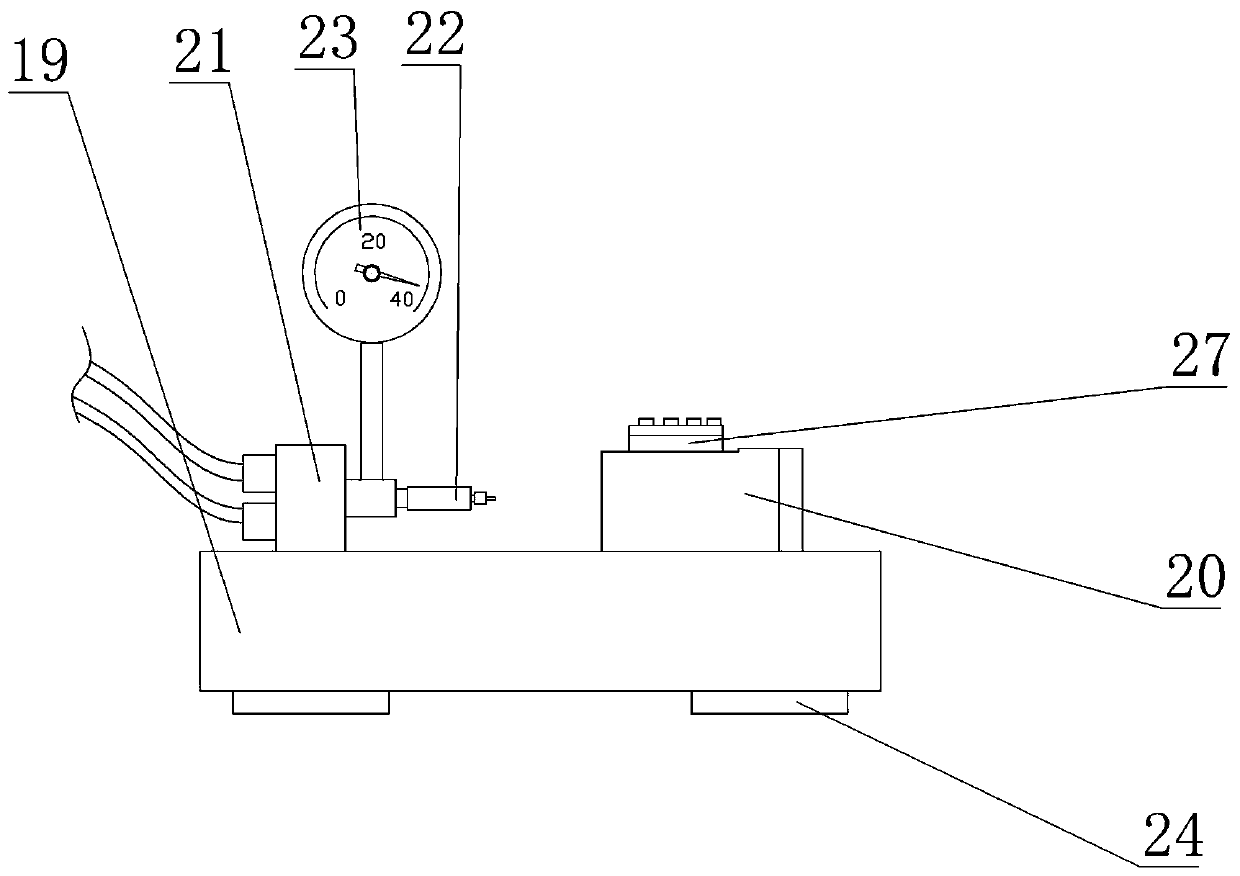

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as figure 1 As shown, the structural principle diagram of the concrete durability test device of the present invention is provided, figure 2 Provide the structural representation of test device among the present invention, image 3 The structure diagram of the constant hydraulic source device in the present invention is provided. The concrete durability test device of the present invention is composed of a test device, a constant hydraulic source device and a control circuit. The test device applies pressure and freezes and thaws the concrete specimen 18, The constant hydraulic source device is used to provide pressure oil with constant pressure. The control circuit realizes the measurement of pressure and temperature signals, and controls the test device to apply a constant load to the test piece and perform cycle freeze-thaw treatment. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com