Fatigue durability testing device for transverse stabilizer bar

A technology of a lateral stabilizer bar and a test device, which is applied in the measurement device, the test of mechanical parts, the test of machine/structural parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

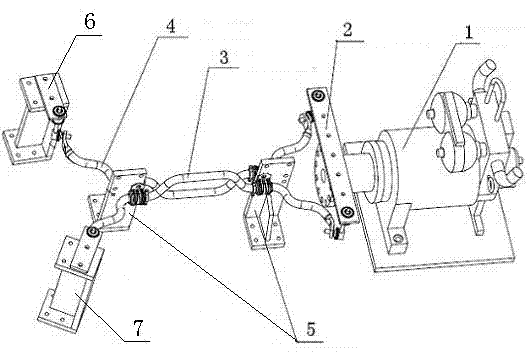

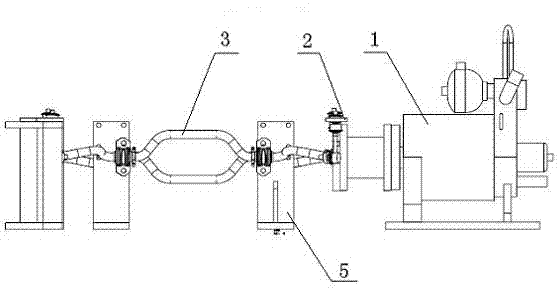

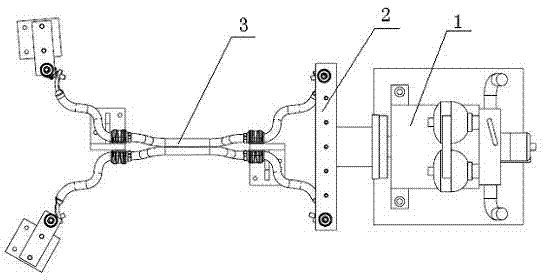

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0015] see figure 1 , figure 2 , image 3 , the present embodiment is a stabilizer bar fatigue endurance test device, in which a torsion drive cylinder 1 is set in the power unit, and the output end of the torsion drive cylinder 1 is provided with a torsion drive swing arm 2 with a long bar flat iron structure, and the torsion drive pendulum Arm 2 is provided with 7 installation holes, and 7 installation holes are located on the same straight line, and fixed screw pin is housed in the installation hole, and the diameter of screw pin is clearance-matched with the connecting hole at the end of the stabilizer bar. The torsional drive swing arm 2 is placed perpendicularly to the axial centerline of the torsional drive cylinder 1 and is provided with an eccentric value to generate a vibration effect.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com