Method for predicting service life of reinforced concrete bridge under conditions of seasonal corrosion and fatigue coupling

A reinforced concrete, life prediction technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, testing wear resistance, etc., can solve the problems of seasonal environmental changes and fatigue coupling effects that have not been studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

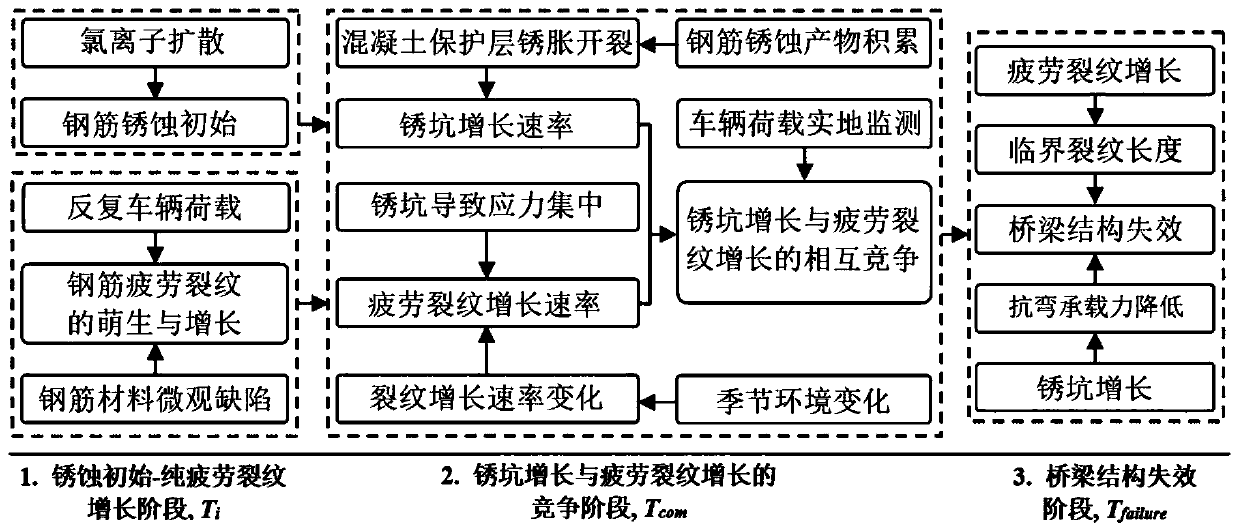

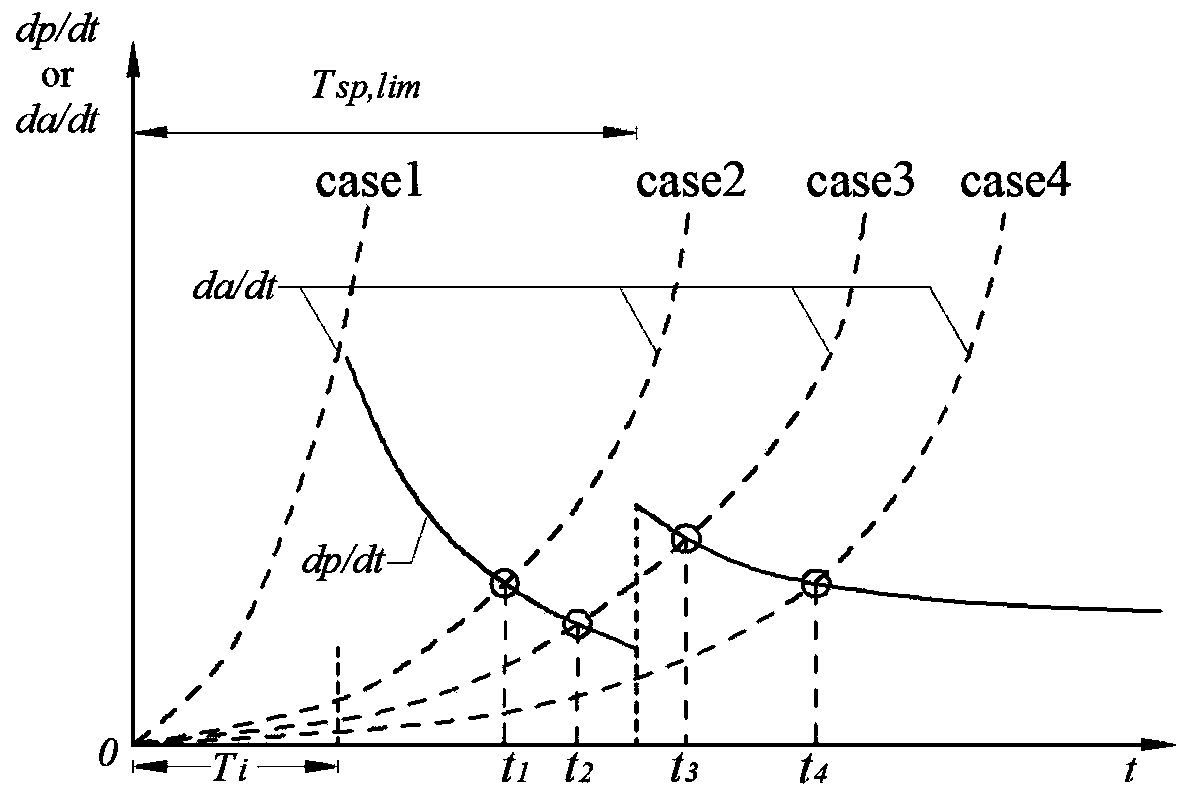

[0115] Such as Figure 1-4 As shown, this embodiment discloses a method for predicting the life of reinforced concrete bridges under the coupling of seasonal corrosion and fatigue. The detailed steps of the calculation method are as follows:

[0116] (1) Based on Fick's second diffusion law, the initial time of corrosion of steel bars in concrete is obtained; at the same time, before the initial corrosion of steel bars, the analysis of small crack growth and near-threshold crack growth is used to obtain the pure fatigue cracks of steel bars caused by material microscopic defects and vehicle loads length of growth;

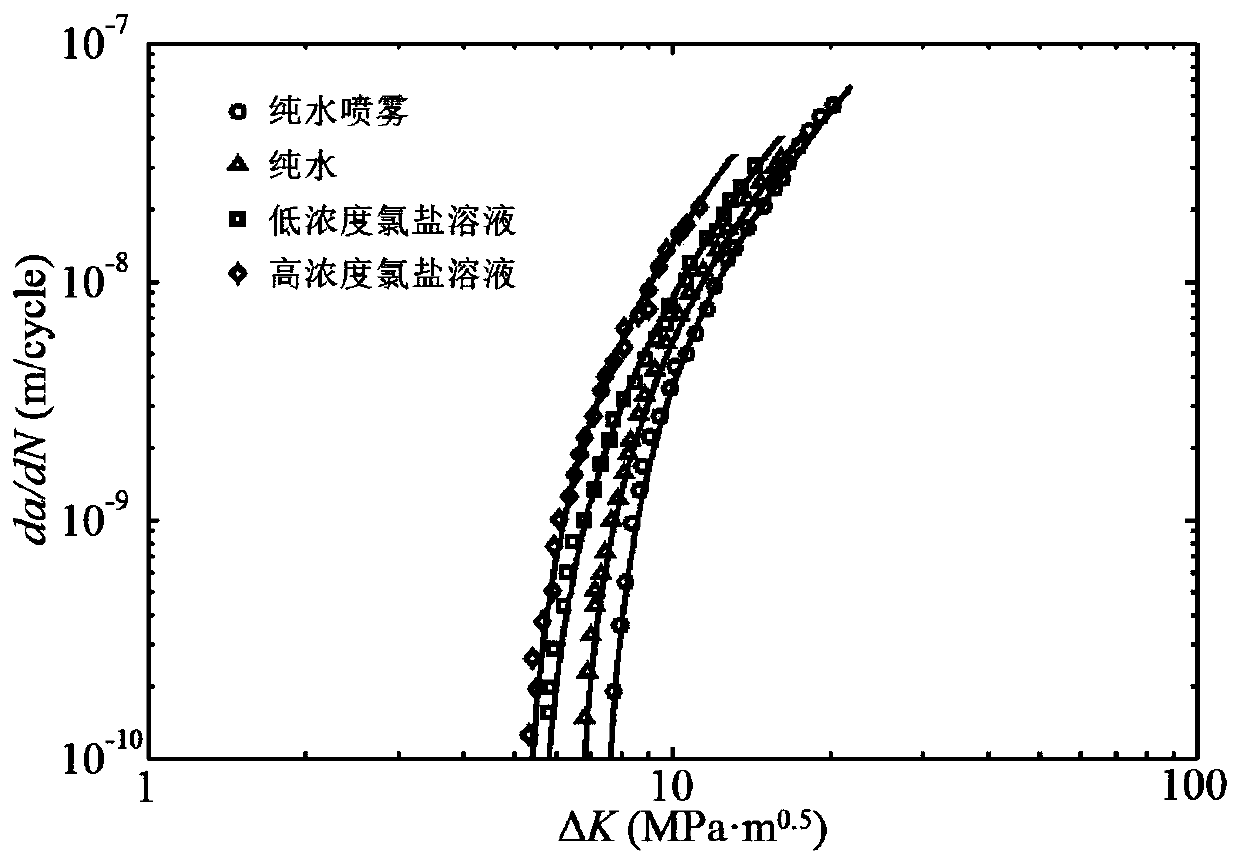

[0117] (2) Use the corrosion current density to represent the corrosion rate of steel bars, calculate the cracking time of the concrete protective layer and the time from cracking to the critical width, and obtain the steel bar corrosion rate model considering the influence of the rust expansion and cracking damage of the concrete protective layer; according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com