Life Prediction Method of Reinforced Concrete Bridge Under Seasonal Corrosion and Fatigue Coupling

A technology for reinforced concrete and life prediction, which is applied in the directions of weather resistance/light resistance/corrosion resistance, test material strength by applying repeated force/pulsation force, and measurement device, which can solve the coupling effects of seasonal environmental changes and fatigue that have not been considered in research and other problems, to achieve the effect of novel prediction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

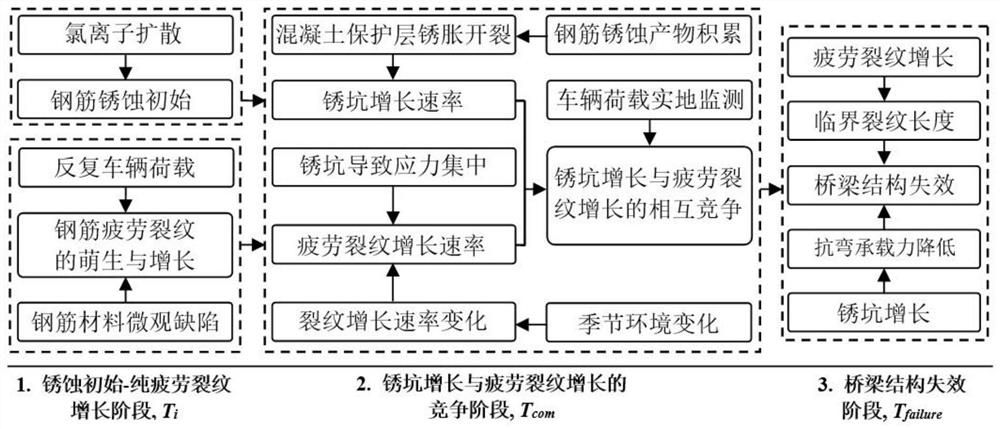

[0115] like Figure 1-4 , The present embodiment discloses a reinforced concrete bridges Life Prediction Methods A Seasonal coupling corrosion and fatigue, the detailed steps of the calculation method is as follows:

[0116] (1) to give corrosion initial time within a reinforced concrete based on Fick's second law of diffusion; the same time, before the steel corrosion initially, a small crack growth and the near threshold crack growth analysis, reinforced pure fatigue crack material microscopic defects and vehicle loading induced growth in length;

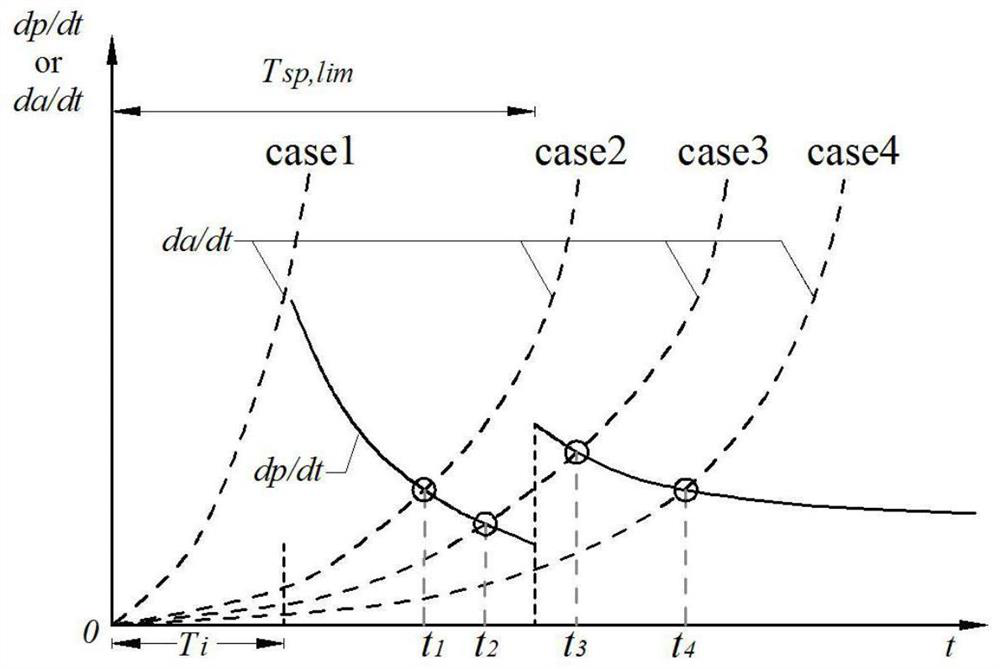

[0117] (2) The corrosion current density is expressed Steel Corrosion Rate, calculated time the concrete cover cracking and the crack to a critical width, be considered Steel Corrosion Rate model of concrete cover cover cracking injury; The corrosion rate model, calculated corroded growth rate of rust pit depth and pit, as described below:

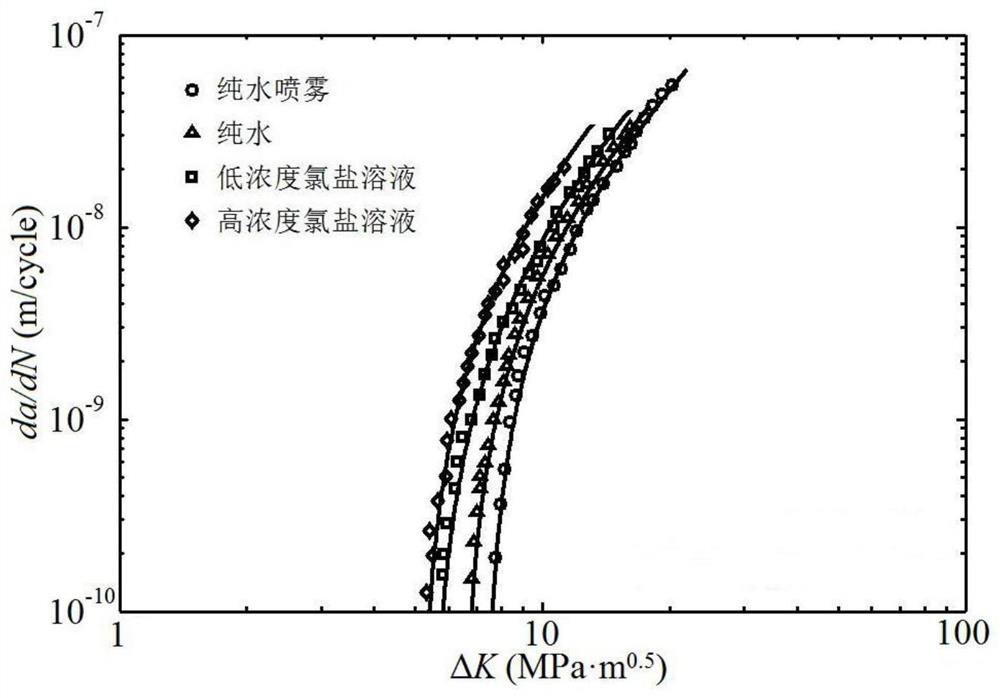

[0118] In the fatigue test carried out reinforcement or finite element analysis at varying degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com