Experimental device and testing method for rapidly determining corrosion rate of reinforcing steel bars

A technology for rapid determination of corrosion of steel bars, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc. It can solve the problems of low test accuracy, crevice corrosion of steel bar samples, and poor validity of experimental test results. Accurate, proven effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

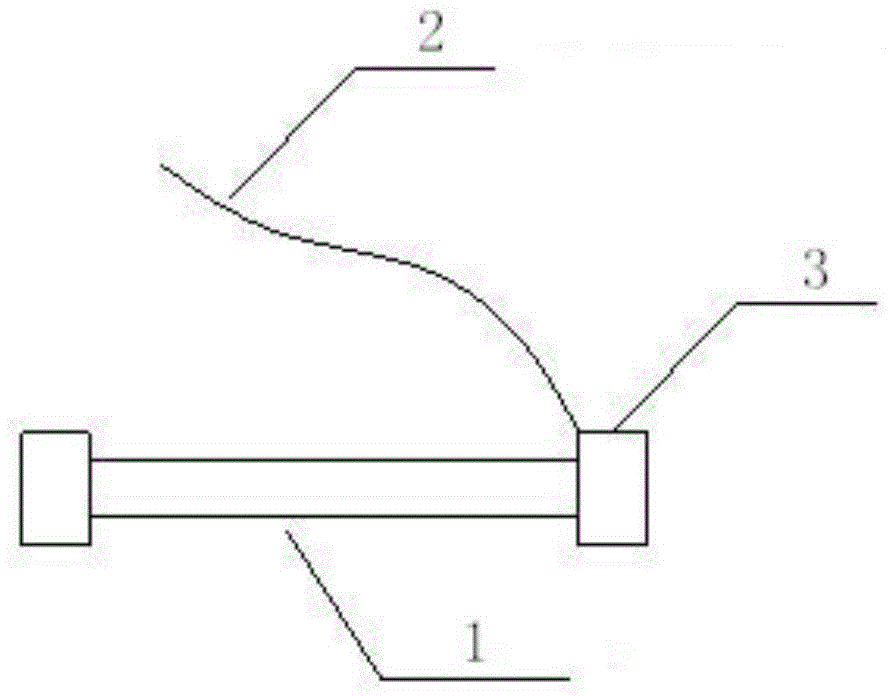

[0023] First prepare the sample: according to figure 1 To make the sample, select 1# and 2# rod-shaped steel bar samples with φ16×125mm to remove the surface oxide scale. One end of the steel bar 1 is welded with the wire 2, and the surface of the wire is covered with an insulating protective sheath. The end of the steel bar and the The wires are sealed with epoxy resin 3, while the exposed length of the steel bars is 100mm.

[0024] Next, prepare the solution: use deionized water with a conductivity of less than 2 μs / cm to prepare the solution, and prepare the anode concrete simulation liquid and the cathode concrete simulation liquid. The anode concrete simulation liquid is a hydroxide containing 0-15% sodium chloride Calcium solution, the cathode concrete simulation fluid is a saturated calcium hydroxide solution.

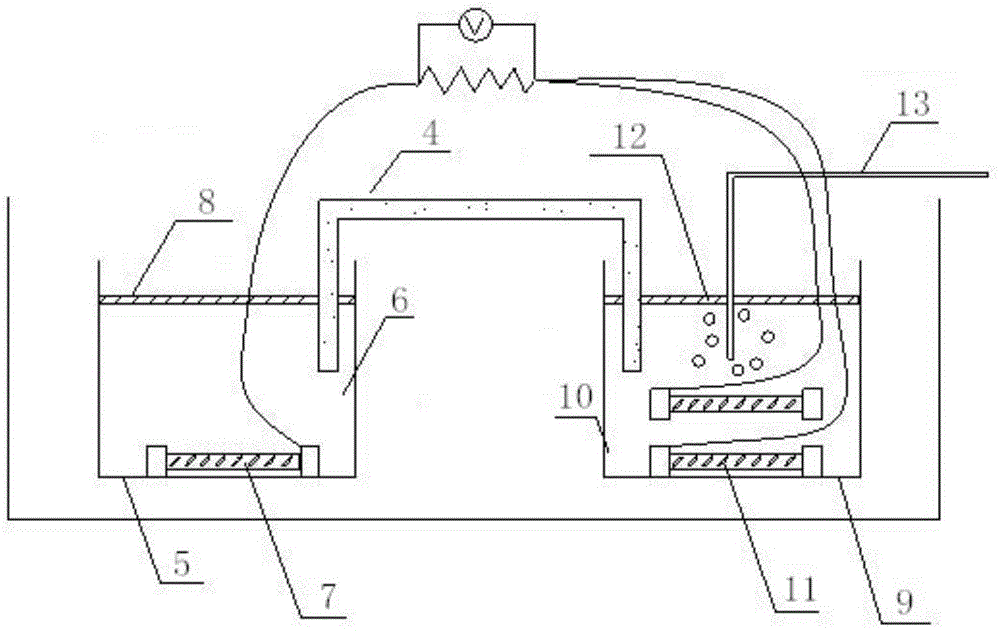

[0025] Set up the device and mount the specimen: follow figure 2 Build the experimental device, including the anode test mechanism, cathode test mechanism, c...

Embodiment 2

[0029] First prepare the sample: according to figure 1 To make the sample, select 1# and 2# bar-shaped steel bar samples with φ11.3×125mm without removing the surface oxide scale. One end of the steel bar 1 is welded with the wire 2, and the surface of the wire is covered with an insulating protective sheath. The ends and wires are sealed with epoxy resin 3, and the exposed length of the steel bar is 60mm.

[0030] Next, prepare the solution: use deionized water with a conductivity of less than 2 μs / cm to prepare the solution, and prepare the anode concrete simulation liquid and the cathode concrete simulation liquid. The anode concrete simulation liquid is a hydroxide containing 0-15% sodium chloride Calcium solution, the cathode concrete simulation fluid is a saturated calcium hydroxide solution.

[0031] Set up the device and mount the specimen: follow figure 2 Build the experimental device, including the anode test mechanism, cathode test mechanism, current test device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com