Long term monitoring sensor for steel bar corrosion in steel concrete member

A reinforced concrete and monitoring sensor technology, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problem that the area of cathode and anode does not conform to the actual situation, increase the permeability of concrete at the test site, and make it difficult to insert and locate the steel mesh and other problems, to achieve the effect of convenient on-site positioning, intuitive measurement and simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

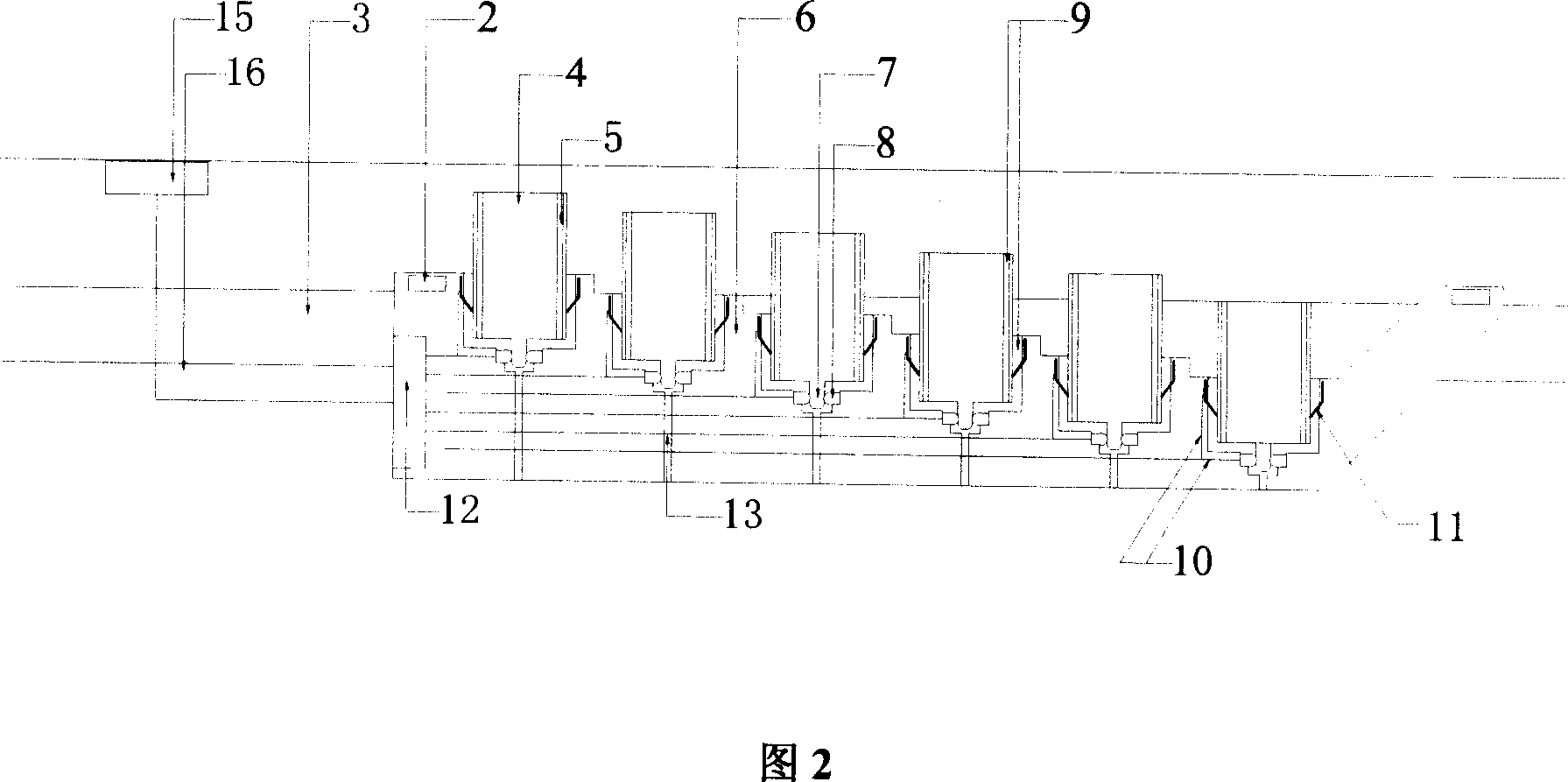

[0043] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

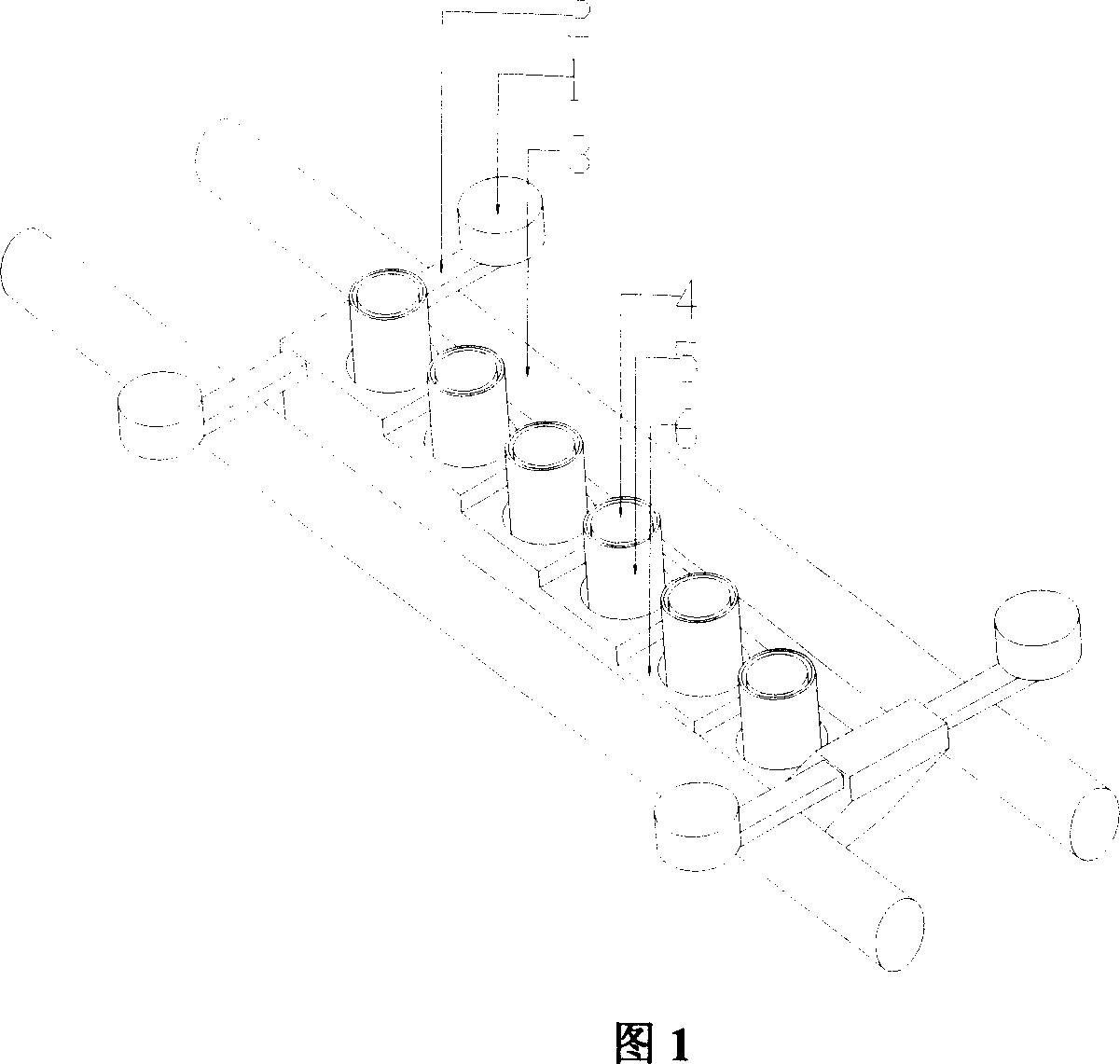

[0044] The structure of the sensor used in the present invention is shown in Figure 1 and Figure 2, including a stepped base 6, an electrode rod inserted in the fixed groove of the stepped base 6, and a cable interface connected to the wire 10 drawn from the electrode rod 12.

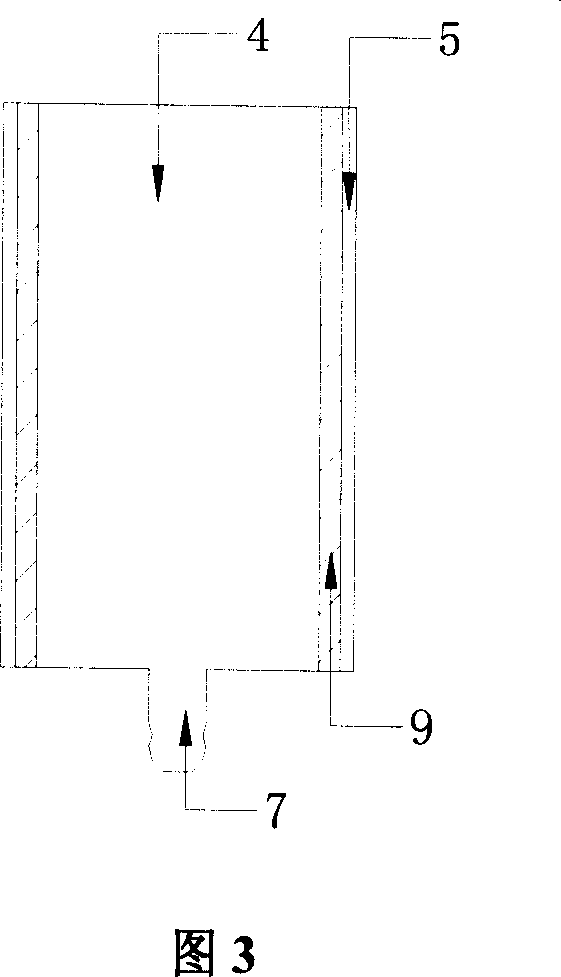

[0045] The electrode rod is composed of a steel bar 4 as an anode and a stainless steel tube 5 as a cathode. Choose the steel bar identical with the used steel bar material of engineering, process the steel bar 4 of certain diameter with lathe as anode, the length of steel bar 4 is determined by the protective layer thickness of structural steel bar (as the protective layer thickness of 30mm, then the length of steel bar It is 30-5+10=35mm). Simultaneously make a stainless steel tube 5 with the same length as the steel bar 4 as the cathode, and the inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com