Method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components

A reinforced concrete, ground-penetrating radar technology, applied in electromagnetic wave detection, weather resistance/light resistance/corrosion resistance, measurement devices, etc., can solve problems such as misjudgment, affecting reflected wave changes, and placing sensors in appropriate places on steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

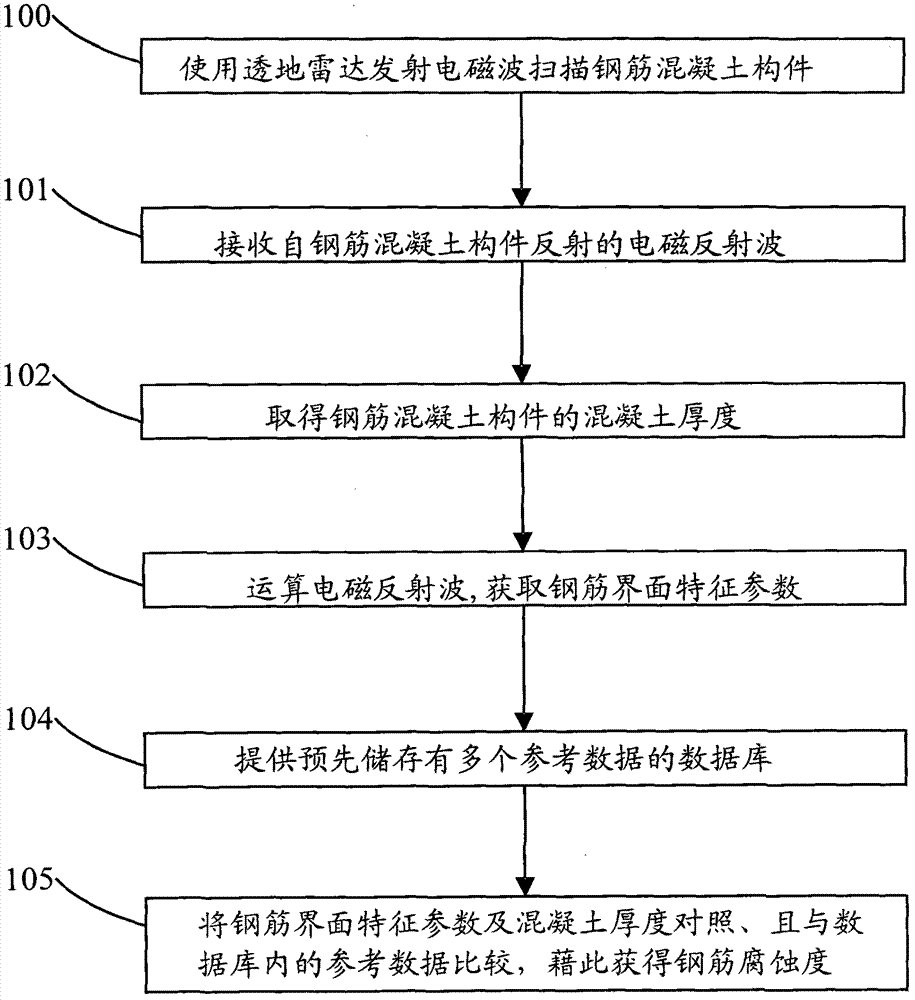

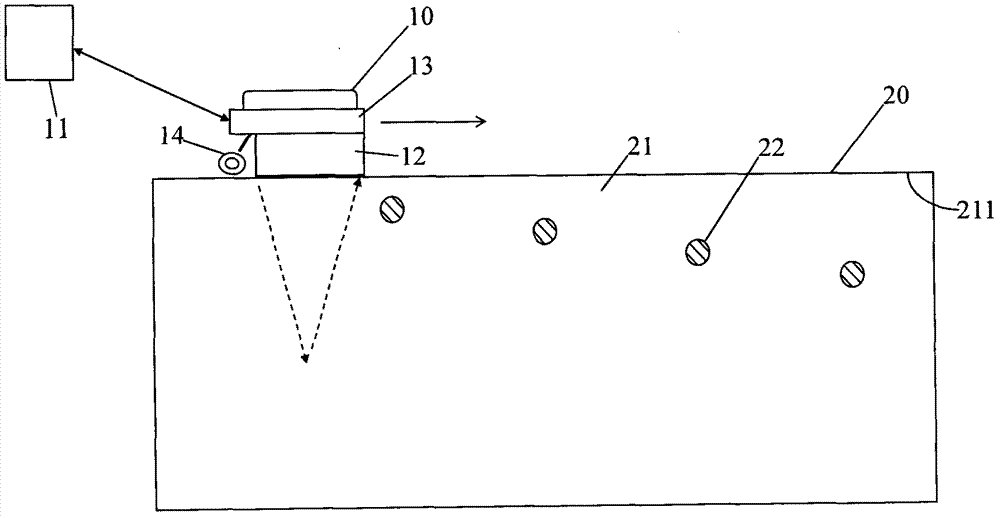

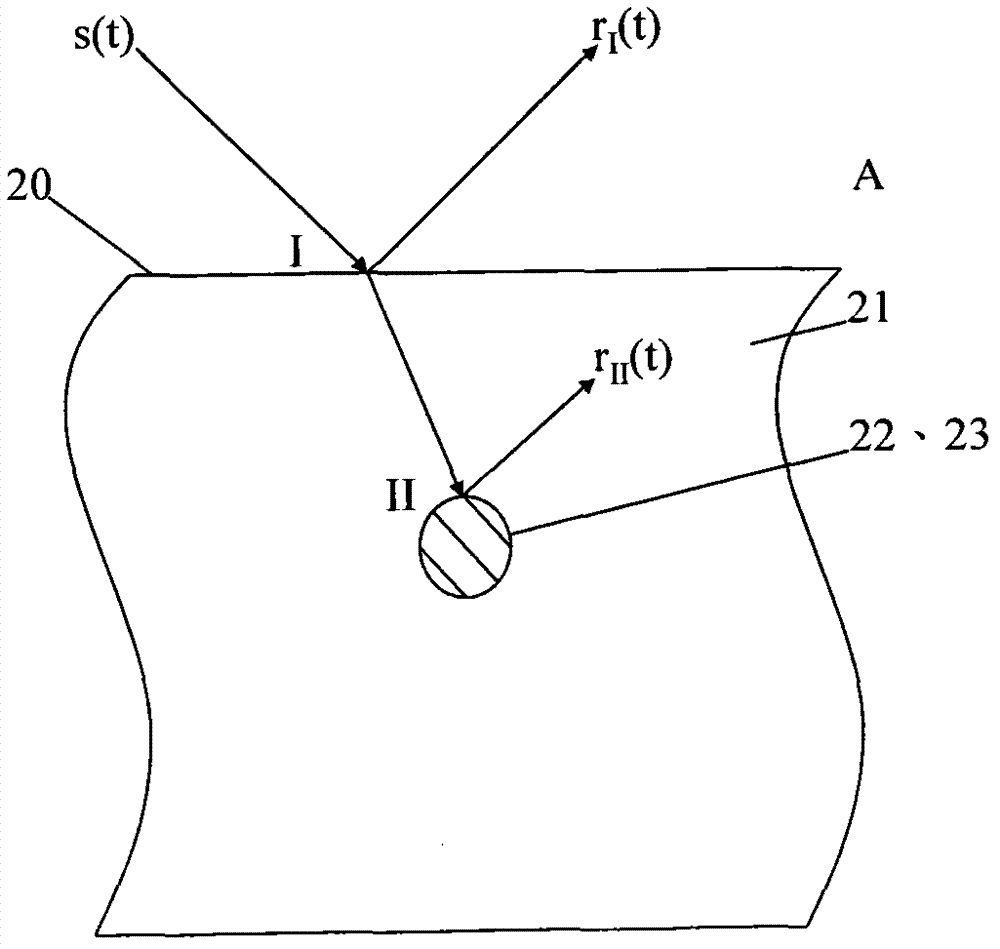

Method used

Image

Examples

experiment example

[0084] A. Experimental content: The experimental content is divided into an experimental group and a control group. The experimental group is to conduct a ground-penetrating radar steel corrosion test, and at the same time use a ground-penetrating radar to do a steel corrosion test. In the control group, the ground penetrating radar steel bar corrosion test was carried out, and at the same time, the steel bar corrosion test was done with a half-cell potentiometer.

[0085] I. Experimental group experiment content:

[0086] a. Accelerated corrosion test of steel bars:

[0087] In this experimental example, a DC power supply is used to apply current to accelerate the corrosion rate of steel bars. The experiment is to place concrete on a titanium mesh, and immerse part of the concrete and titanium mesh in water, but care should be taken not to contact the steel bars with water. Next, the anode of the DC power supply is connected to the steel bar, and the cathode is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com