Corrosion inhibitor gel microsphere with intelligent pH value controlled release function and its preparation method and use

A technology of gel microspheres and controlled release, which is applied in the field of corrosion inhibitor gel microspheres and their preparation, and can solve the problems of pH drop of steel/concrete interface, steel corrosion, corrosion inhibitor inactivation, hydrolysis and degradation, etc. , to achieve the effect of good monodispersity, realization of intelligence, and improvement of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

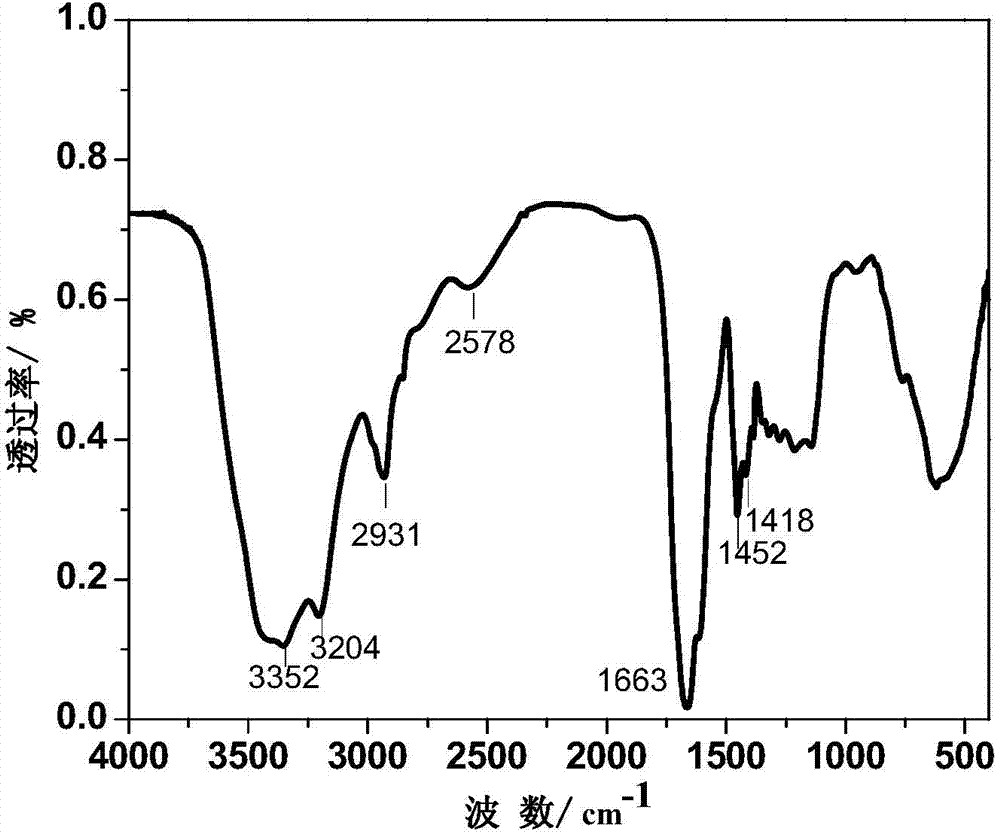

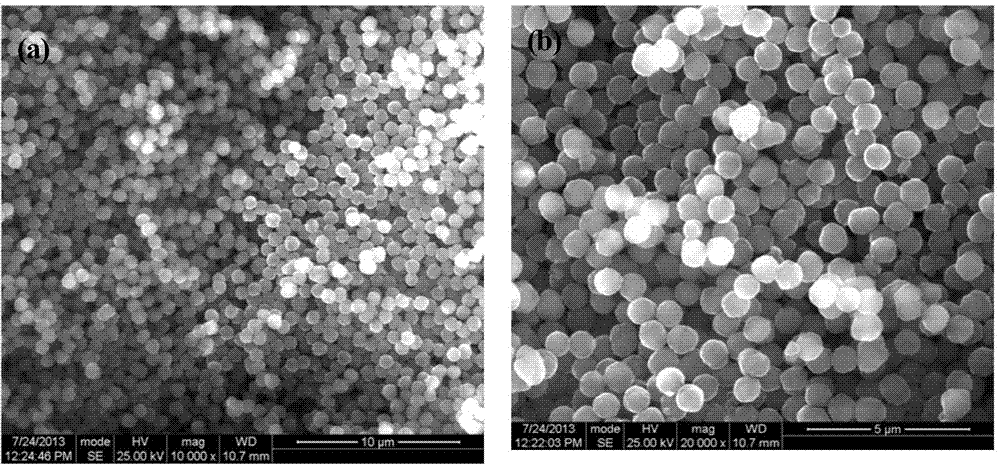

[0025] First weigh acrylic acid (AAc) and acrylamide (AAm) monomer 10g respectively, (wherein (AAc) / (AAm) weight ratio is 1:2), 0.6g N,N,-methylenebisacrylamide, 0.1 g of azobisisobutyronitrile, 1.5 g of sodium benzoate, 4 g of water and 80 g of cyclohexane were mixed by ultrasonic dispersion and dissolved, and then added to a reaction flask with mechanical stirring and a condenser tube. Then, the polymerization reaction was carried out for 18 hours at a stirring speed of 200 rpm and a reaction temperature of 50° C. to obtain a milky white emulsion product. After cooling to room temperature, the product was vacuum filtered, washed and dried to obtain corrosion inhibitor gel microspheres. The surface infrared reflectance spectrum of the prepared corrosion inhibitor gel microspheres is as follows: figure 1 , the surface morphology is as figure 2 (a).

Embodiment 2

[0027] Weigh respectively methacrylic acid (MAA) and acrylamide (AAm) monomer 5g, (wherein (MAA) / (AAm) weight ratio is 1:3), 0.6g N,N,-methylenebisacrylamide, 0.1 g of azobisisobutyronitrile, 1.5 g of sodium benzoate, 4 g of water and 80 g of cyclohexane were mixed by means of ultrasonic dispersion and dissolved, and then added to a reaction flask with mechanical stirring and a condenser tube. Then, the polymerization reaction was carried out for 18 hours at a stirring speed of 200 rpm and a reaction temperature of 50° C. to obtain a milky white emulsion product. After cooling to room temperature, the product was vacuum filtered, washed and dried to obtain corrosion inhibitor gel microspheres. The surface morphology of the gel microspheres is as figure 2 (b).

Embodiment 3

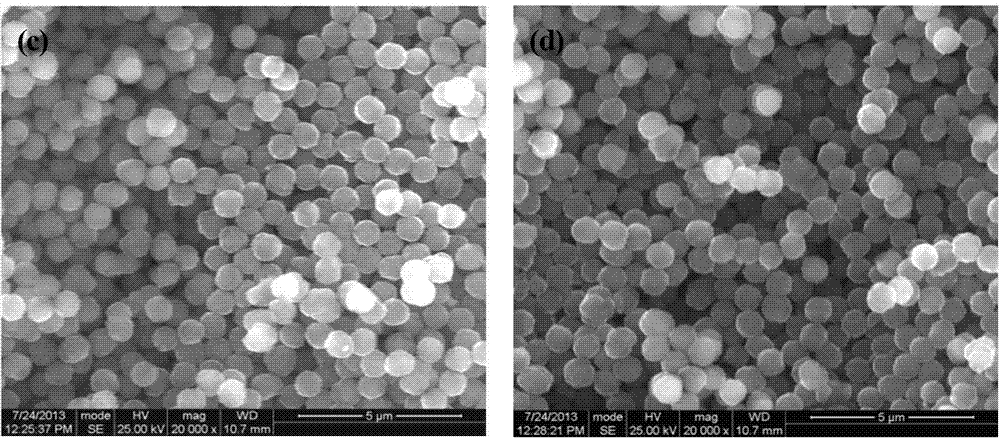

[0029] Weigh respectively 10g of acrylic acid (AAc) and acrylamide (AAm) monomers, (wherein (AAc) / (AAm) weight ratio is 1:2), 0.6g N,N,-methylenebisacrylamide, 0.2g Azobisisobutyronitrile, 1.0g of sodium benzoate, 4g of water and 80g of methanol were fully dissolved and mixed by ultrasonic dispersion, and then added to a reaction flask with mechanical stirring and a condenser. Then, the polymerization reaction was carried out at a stirring speed of 300 rpm and a reaction temperature of 40° C. for 22 hours to obtain a milky white emulsion product. After cooling to room temperature, the product was vacuum filtered, washed and dried to obtain corrosion inhibitor gel microspheres. The surface morphology of the microspheres is as figure 2 (c).

[0030]The corrosion inhibitor gel microspheres obtained in this example are placed in an alkaline buffer solution, which is composed of 0.1mol / L sodium borate and 0.1mol / L hydrochloric acid, 0.1mol / L sodium carbonate and 0.1mol / L Sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com