Resistance heating

A heating plate and heating element technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems that the heat carrier cannot be taken out, the fault of the heat carrier is unobtrusive, and the uneven temperature distribution, etc., to achieve simple assembly, Short post-heating times, cheap effects to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

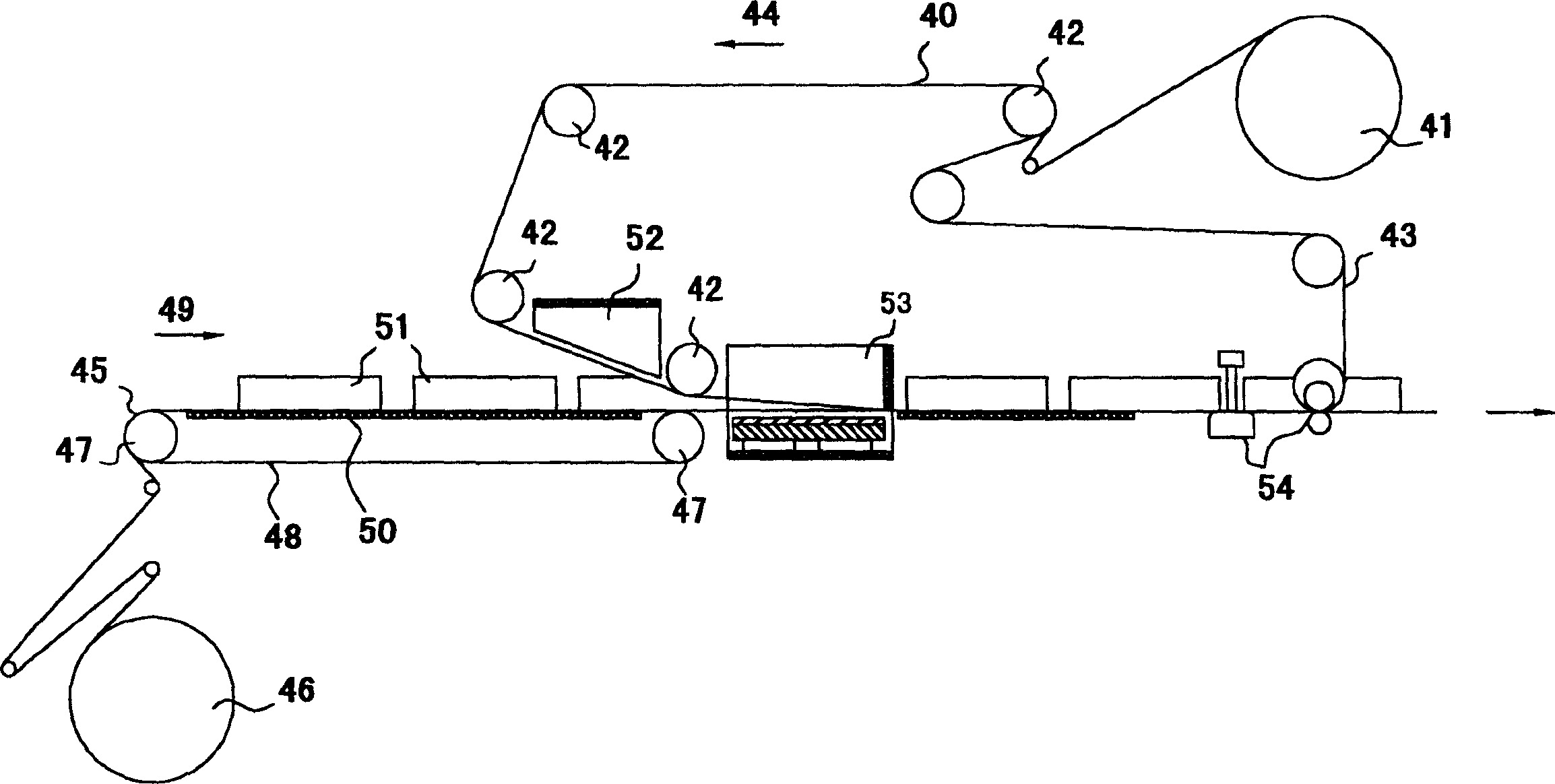

[0048] exist figure 1 In , the top web 40 is unwound from a supply roll 41 and guided on deflection pulleys 42 to individual work stations. The top web 40 is conveyed along a chain conveyor 43 which conveys the top web 40 in the direction of arrow 44 . The back web 45 is conveyed from a supply roll 46 by a chain conveyor 48 driven by a sprocket 47 in the direction of arrow 49 . The back web 45 is guided on a table 50 comprising a cooling plate and an insert formwork. The package contents 51 are then deposited on the moving back web 45 and transported with the back web 45 in the transport direction 49 to further work stations. After the package contents 51 are placed on the bottom web 45, the bottom web 45 and top web 40 are joined together once the top web 40 passes through the preheating station 52. The webs 40, 45 joined to each other, together with the package contents 51, pass through a vacuum chamber 53 formed by a fixed bottom and a lowerable top. When the package c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com