Prefabricated hexagonal energy pile and manufacturing method thereof

A technology of hexagonal and energy piles, which is applied in the direction of sheet pile walls, refrigerators, refrigeration components, etc., can solve the problems of the decline of the overall bearing capacity of pile foundations, achieve high compactness, strong operability, save underground space and The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the patent of the present invention is described in detail below in conjunction with accompanying drawing. The protection scope of the patent of the present invention is not limited only to the description of this embodiment.

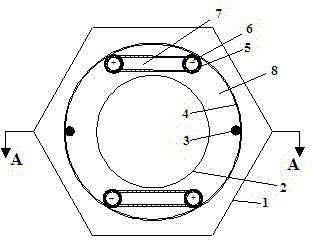

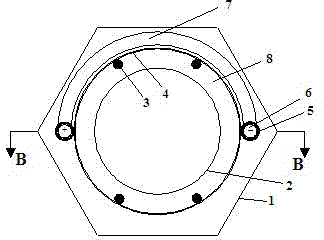

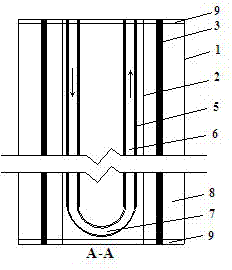

[0033] Such as Figure 1-Figure 4 As shown, a hexagonal prefabricated energy pile, the outer surface is hexagonal 1, the inner surface is circular 2, the reinforcement cage inside the pile body 8 is composed of solid steel bars 3, stirrups 4 and hollow steel pipes 5, heat transfer The tube 6 is arranged in the hollow steel pipe 5; two heat transfer tubes 6 are connected by a heat transfer elbow 7. The advantage of this embodiment is that the heat transfer tube 6 is pre-embedded in the hollow steel pipe 5 as the main reinforcement of the structure, and the through-U-shaped heat transfer system composed of the heat transfer tube 6 and the heat transfer elbow 7 is pre-embedded inside the prefabricated pile, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com