Design and construction for connection node between steel tube-reinforced concrete composite column and reinforced concrete beam

A technology of reinforced concrete beams and concrete-filled steel tubes, which is applied in the directions of buildings and building structures to achieve the effect of saving construction time, convenient construction and simple joint form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

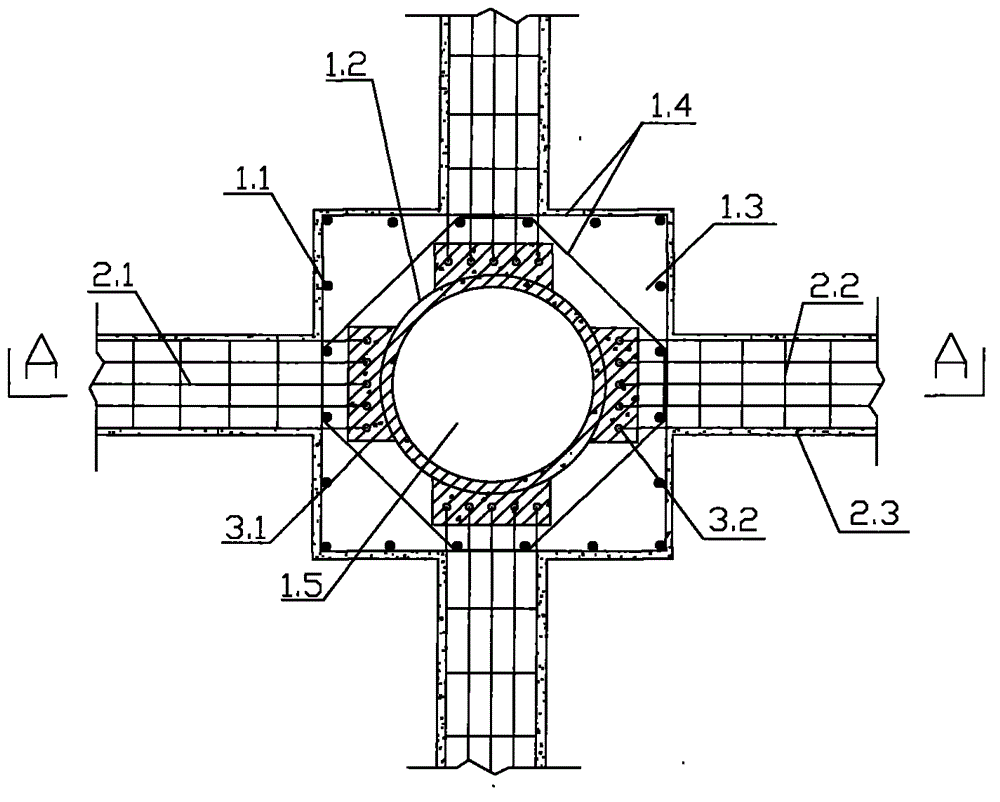

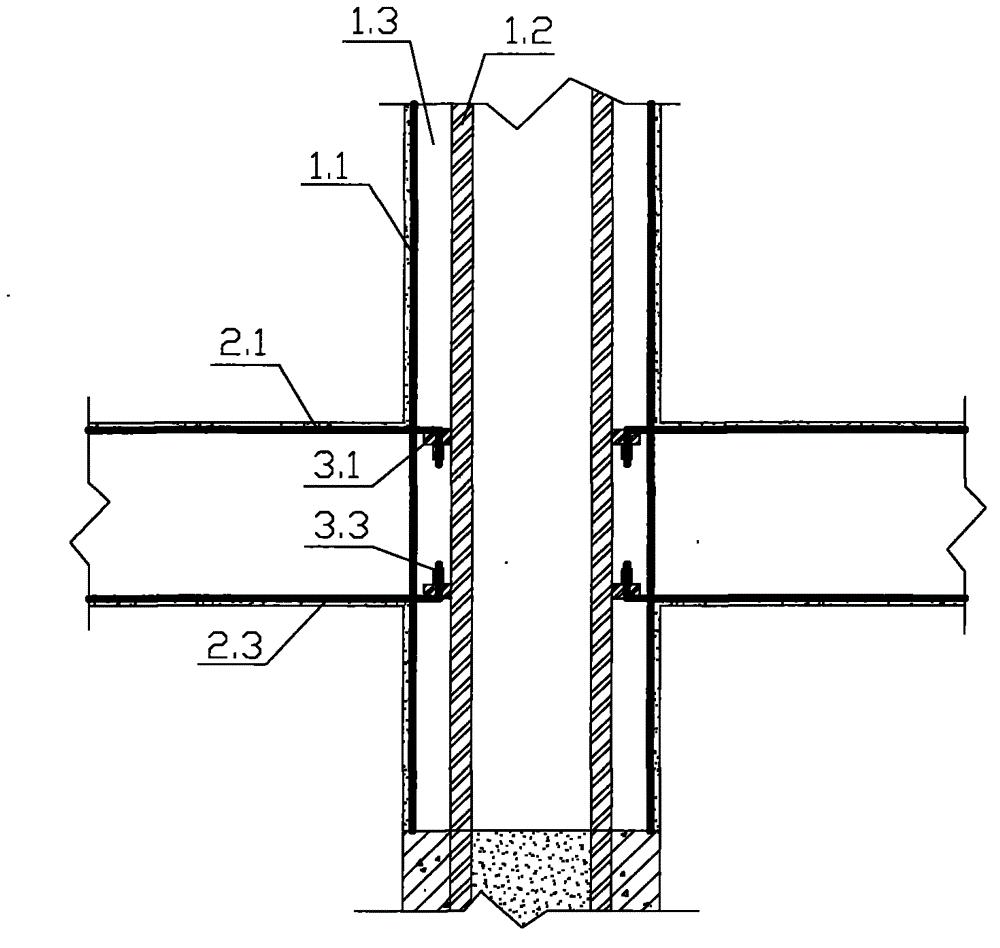

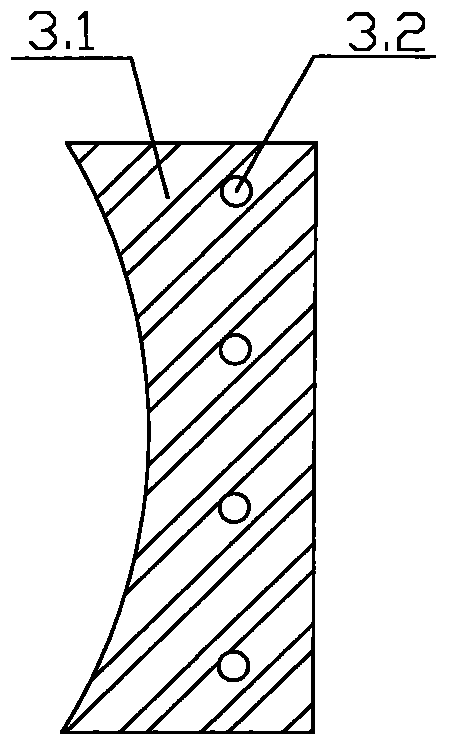

[0023] Examples see Figure 1 to Figure 3 As shown, a joint of concrete-filled steel tube composite column and reinforced concrete beam, the concrete-filled steel tube composite column (1) includes longitudinal reinforcement (1.1), inner steel pipe (1.2), peripheral concrete (1.3), stirrup (1.4 ), concrete (1.5) inside the steel pipe, the reinforced concrete beam (2) at least includes the main reinforcement (2.1), the stirrup (2.2) and the concrete (2.3) with threaded sleeves, and the connecting piece (3) includes at least bolt holes connecting plate (3.1), bolt holes (3.2), and nuts (3.3), the connecting plate with bolt holes is welded on the inner steel pipe (1.2), the threaded main reinforcement of the reinforced concrete beam (2) Pass through the bolt holes (3.2) of the connecting plate (2) with bolt holes and screw on the nuts (3.3).

[0024] For the nodes of the concrete-filled steel tube composite column and the reinforced concrete beam, the inner steel tubes can be ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com