Hangar steel truss structure lifting system and modeling analysis method

A steel grid and hangar technology, applied in the direction of instruments, electrical digital data processing, geometric CAD, etc., can solve the problems of bending deformation of rods, easy occurrence of grids, engineering accidents, etc., to reduce cost increase and avoid rods Effects of adjustments or reinforcements, safety and reliability guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

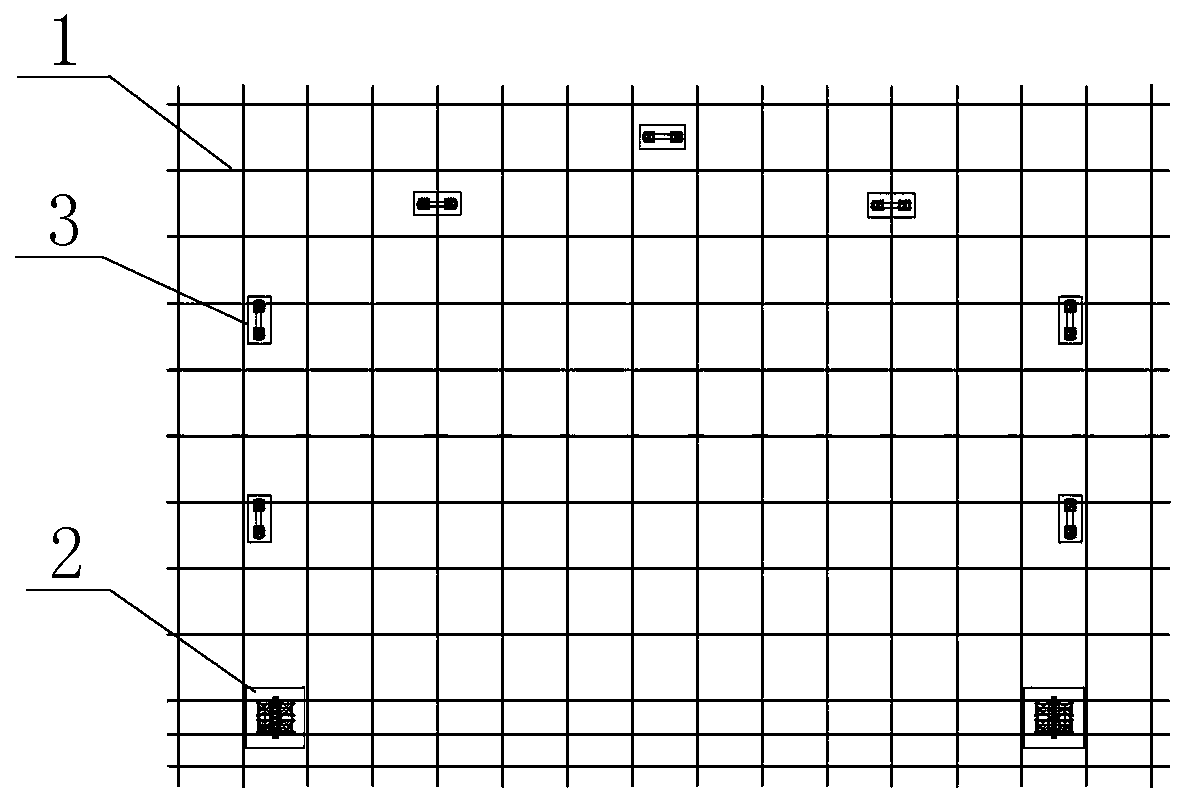

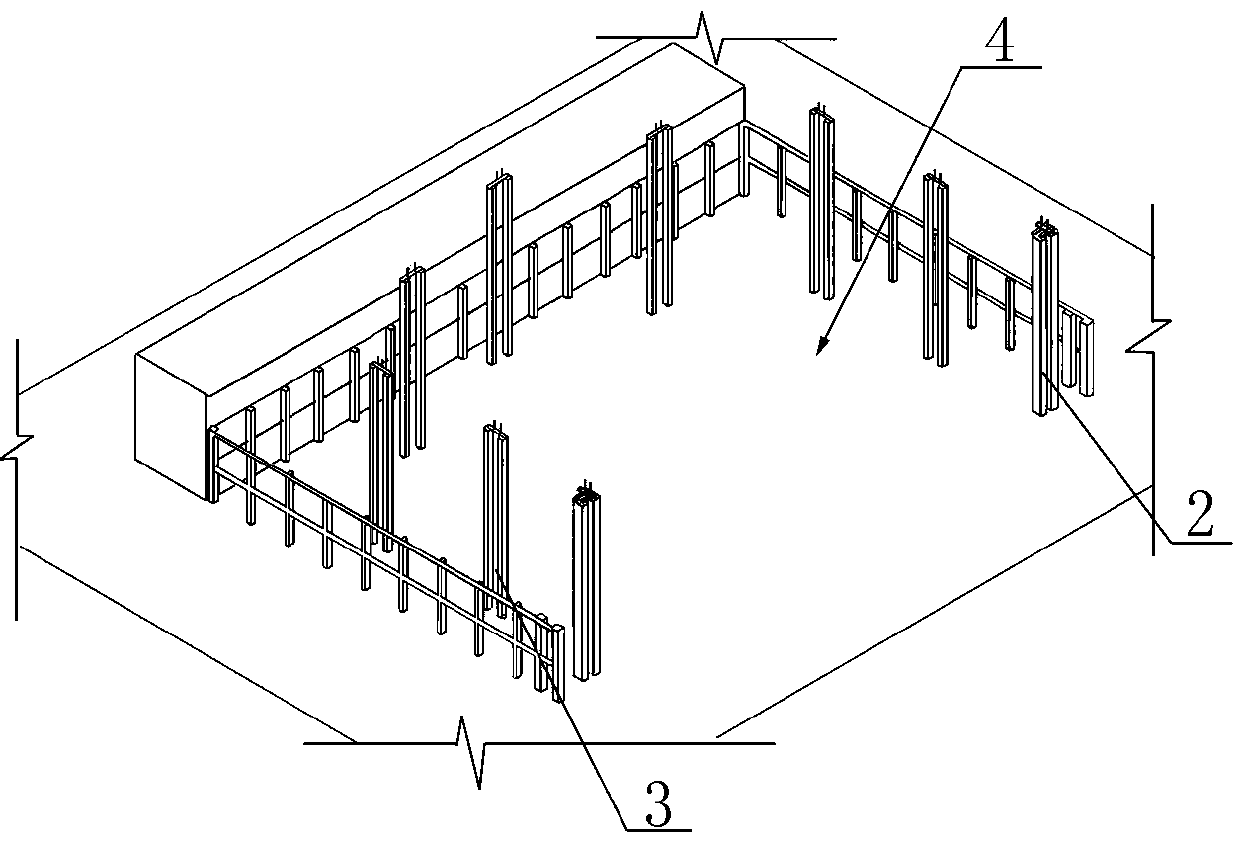

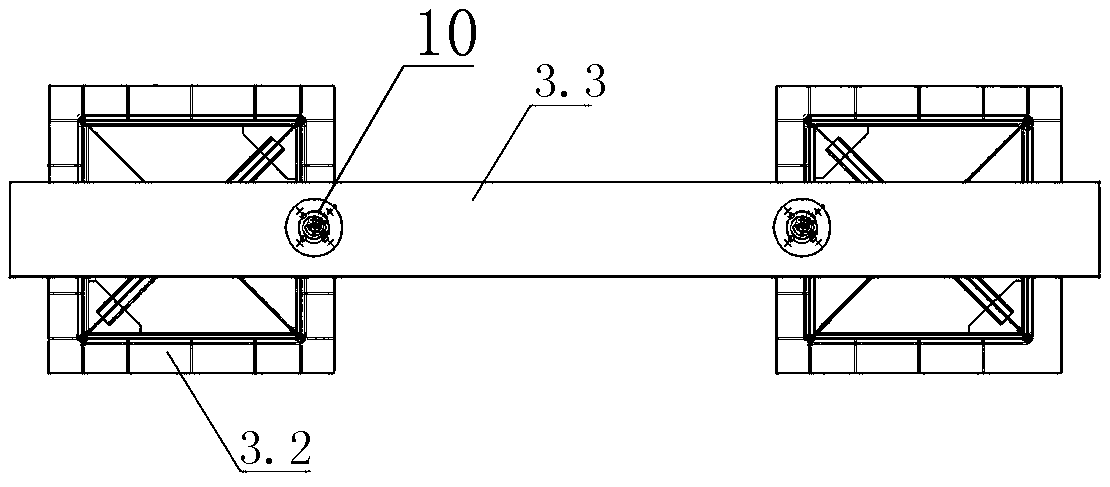

[0041] Such as Figure 1-9 As shown, the lifting system of this hangar steel grid structure is used to lift the hangar steel grid structure 1 to be constructed; it includes a door head support frame 2 and a hall support frame 3; the door head support frame 2 There are two, respectively arranged in the hangar 4 at the left and right sides of the hangar door, and the distance between the door head support frame 2 and the longitudinal side of the corresponding side of the hangar 4 is 8m ~ 12m, the door head The distance between the support frame 2 and the front side of the hangar 4 is 4m to 5m; the top of the door support frame 2 is provided with a first lifting device; The left sideline, rear sideline and right sideline are arranged at intervals, and the distance between adjacent hall support frames 3 is 25m-35m; The support frames 2 are vertically aligned, and the hall support frames 3 on the left and right sides are arranged in one-to-one correspondence; the hall support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com