Control system of converter valve hall inner wall cleaning robot

A technology for cleaning robots and control systems, applied in the field of control systems, can solve problems such as low efficiency, high risk, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

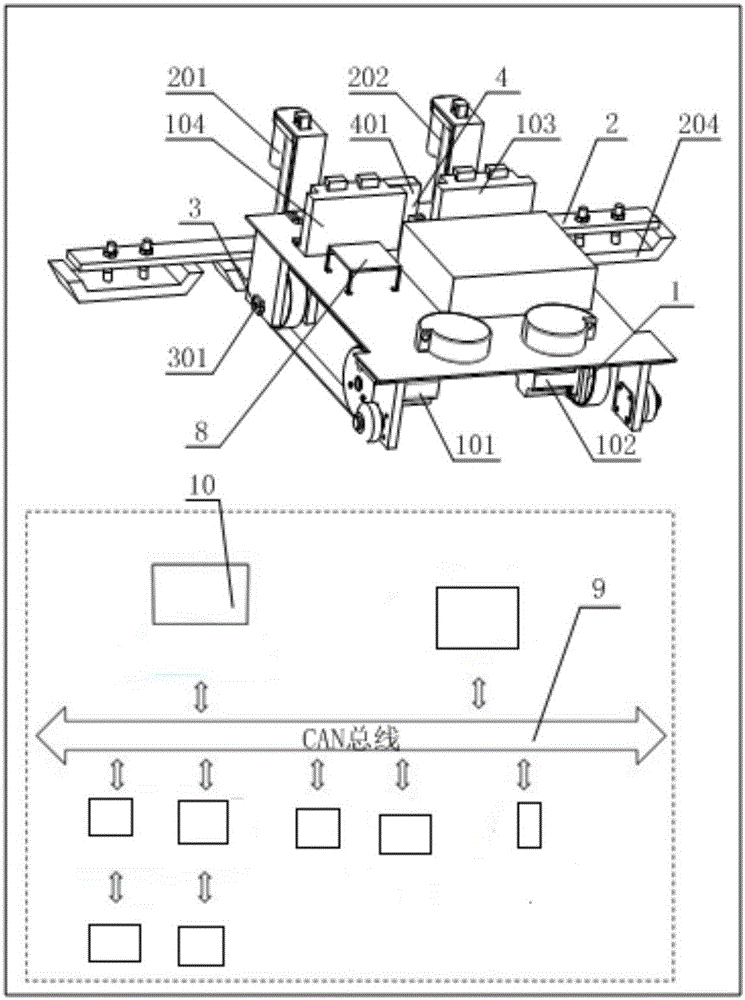

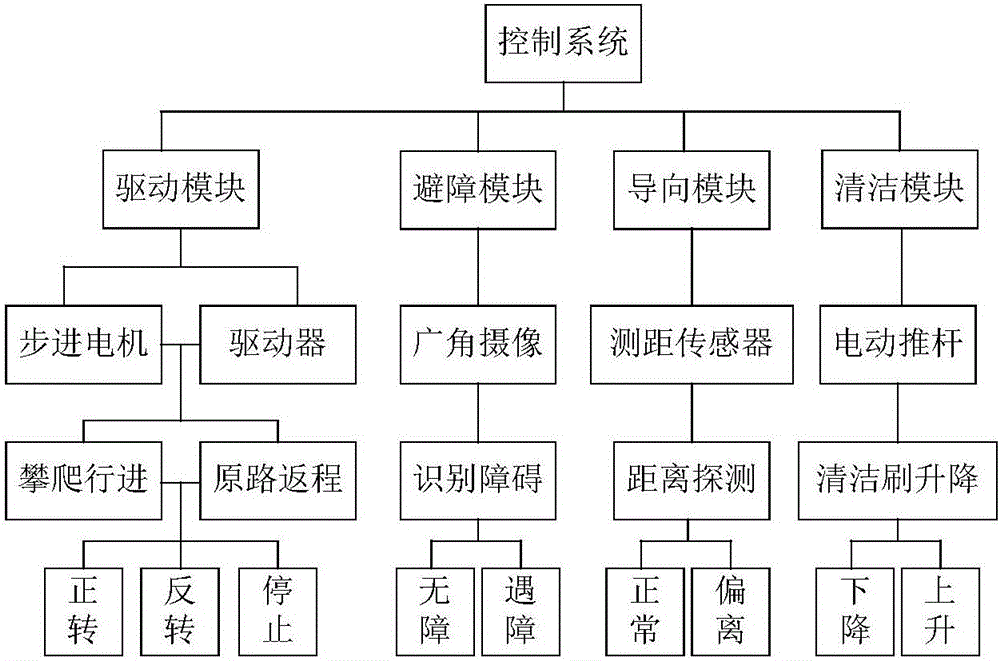

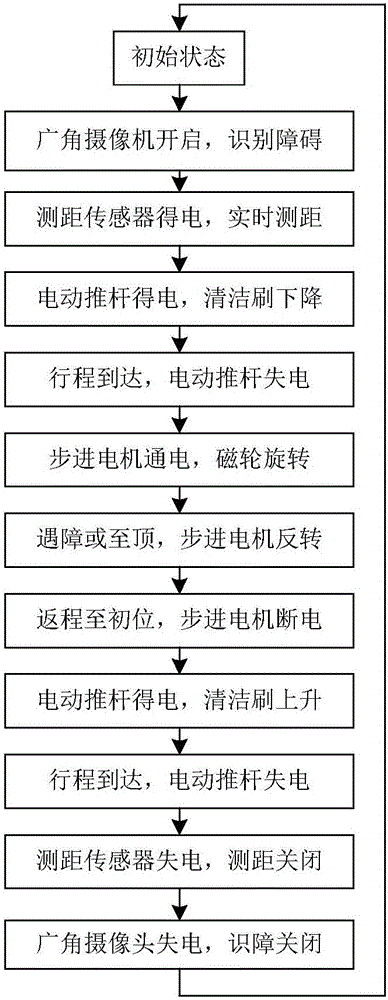

[0023] refer to Figure 1 to Figure 3 , the control system of the cleaning robot for the inner wall of the converter valve hall, including at least one driving module 1, at least one controlled object stepping motor, electric push rods 201, 202, cleaning module 2, guiding module 3, obstacle avoidance module 4, and computer PC Terminal 10, single-chip microcomputer chip 8 and CAN bus 9, described single-chip microcomputer chip 8 is respectively connected with drive module 1, cleaning module 2, guide module 3, obstacle avoidance module 4, computer PC end 10; Wherein,

[0024] Described computer PC end 10 is connected with CAN bus 9, and described computer PC end 10 receives all bus messages from described CAN bus 9, to complete described driving module 1, cleaning module 2, guiding Initialization of module 3 and obstacle avoidance module 4 and monitoring of working status;

[0025] The drive module 1 is connected to the CAN bus 9, and the drive module 1 obtains navigation infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com