Method for measuring migration depth and apparent migration coefficient of chloride ions in concrete

A technology of migration coefficient and concrete, applied in measurement devices, surface/boundary effects, instruments, etc., can solve the problems of limiting the accurate application of silver nitrate color development method, high equipment requirements, and cumbersome test steps for layer-by-layer sampling, so as to improve discoloration. The boundary does not appear, the construction operation is simple, and the test is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

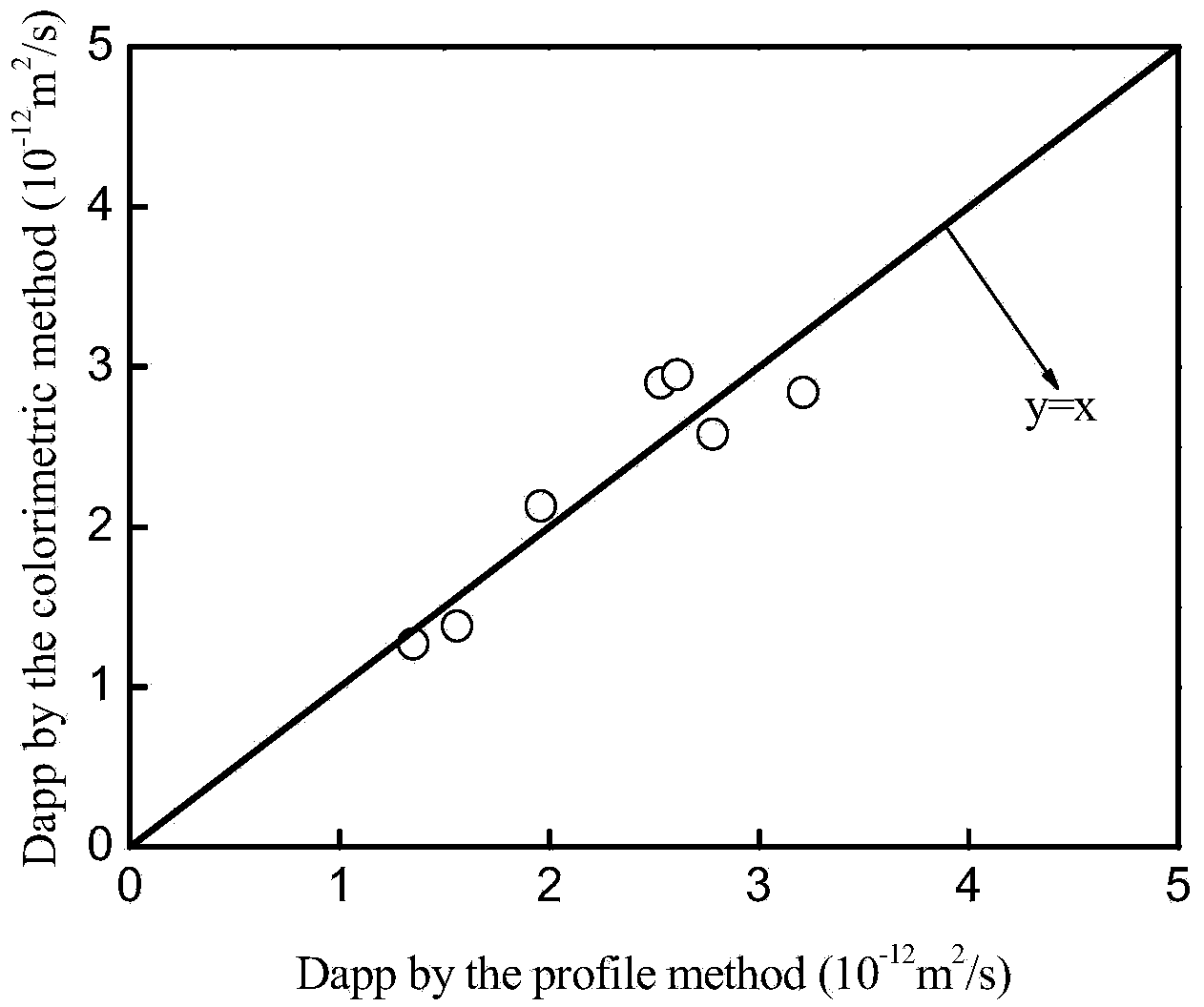

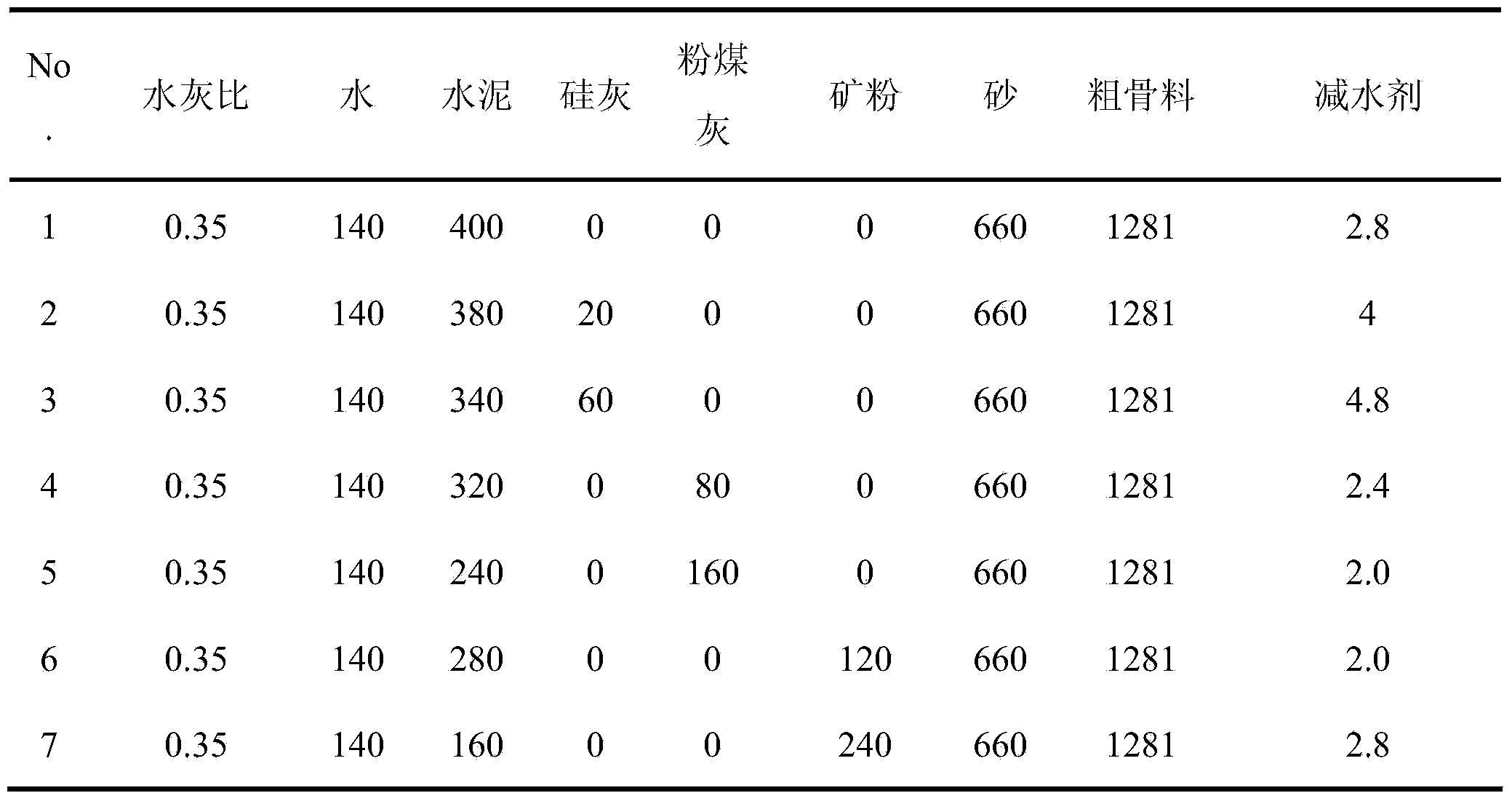

[0023] Examples 1 and 2 of the present invention both adopt concrete specimens to carry out natural diffusion experiments. The immersion liquid adopts 3.5% NaCl solution, and the immersion time is 300 days. The test fits are shown in Table 1.

[0024] Table 1 Example 1, 2 concrete mix ratio

[0025]

[0026] After reaching the immersion age designed for the experiment, according to NT Build443, the chloride ion content of each layer of samples was measured by the Profile method of layer-by-layer cutting sampling and chemical analysis. The cylindrical specimen is fixed on the cutting machine tool, and the cutting machine is used to dry cut the powder layer by layer. The powder thickness of each layer is 1mm. The obtained powder was measured by the acid-dissolution method to measure the chloride ion content in the powder, and the apparent diffusion coefficient of the specimen was calculated according to the least square method and formula (1).

[0027] C ...

Embodiment 2

[0030] (1) After immersing the cylindrical specimen in 3.5% NaCl solution for 300 days for natural diffusion experiment, place the specimen horizontally, apply a force in the middle of the upper part, and apply supporting force at 1 / 3 of the lower part, along the permeable surface Split in parallel directions until the specimen is completely split;

[0031] (2) Adopt the vertical section spraying method, spray 0.1N silver nitrate solution, and the spraying amount is 300±60ml / m 2 , the ambient temperature is controlled at 20-25 degrees Celsius,

[0032] (3) Measure the discoloration depth by ruler and gauge method. After spraying the silver nitrate solution, about 10-30 minutes later, it depends on the humidity of the experimental environment. When there is no water mark on the section of the specimen, use a thinner pen to draw the discoloration boundary clearly, and then use a ruler to stick to the side of the specimen , test a discoloration depth value every 1cm, test at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com