Multifunctional sensor for monitoring reinforced concrete structure erosion

A reinforced concrete, multi-functional technology, applied in the field of sensors, can solve the problems of time-consuming measurement, limited monitoring parts, and inability to obtain concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

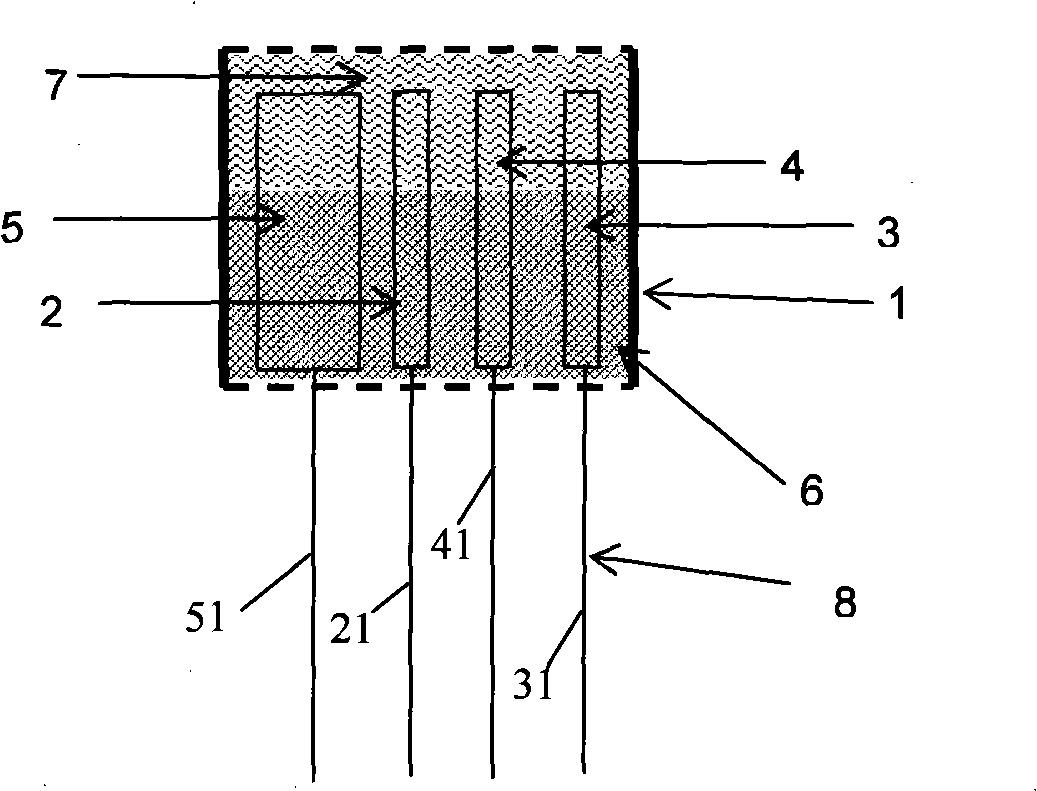

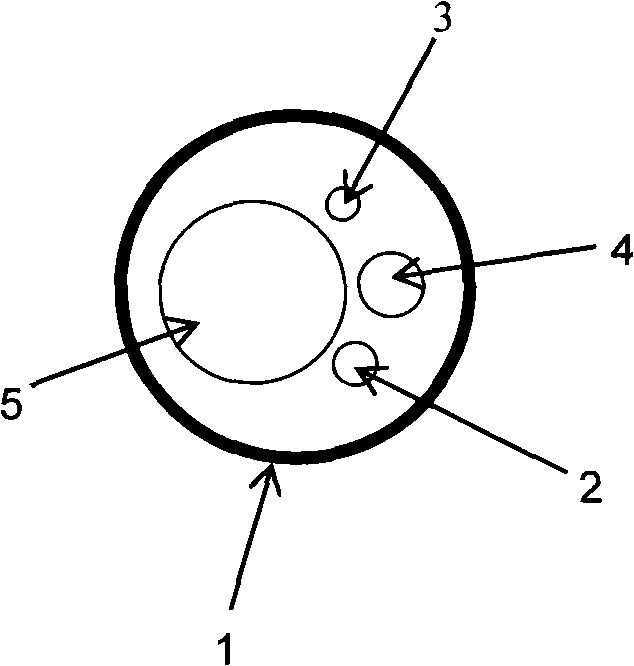

[0056] see figure 1 and 2 , in order to make the structural representation of the multifunctional sensor for monitoring the corrosion of reinforced concrete structures clearer, figure 1 Each probe and electrode are arranged in turn, each probe and electrode in the embodiment are actually according to figure 2 way to arrange.

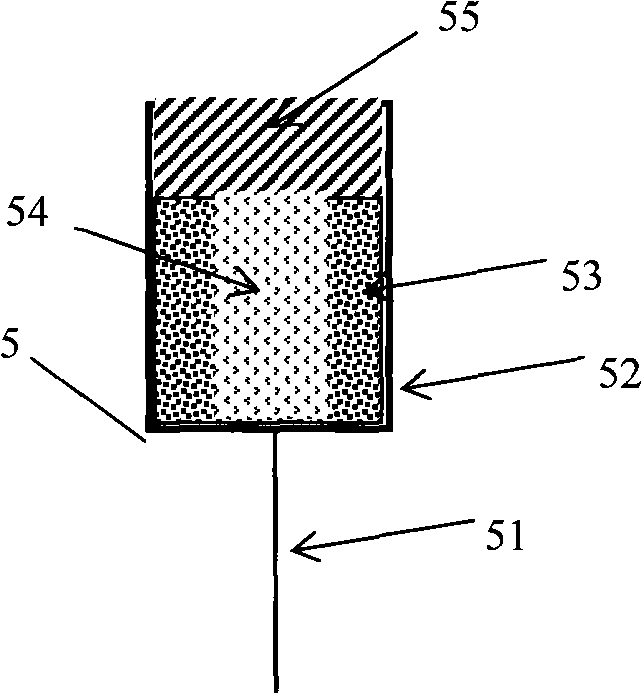

[0057] Multifunctional sensor for monitoring corrosion of reinforced concrete structures has a stainless steel cylindrical housing 1, Cl - Probe 2, pH probe 3, steel bar electrode 4, MnO 2 Reference electrode 5, and outer lead wires 21, 31, 41 and 51.

[0058] Cl - Probe 2, pH probe 3, steel electrode 4 and MnO 2 The reference electrodes 5 are all arranged in the shell 1 and arranged in parallel at intervals, Cl - Probe 2, pH probe 3, steel electrode 4 and MnO 2 The lower ends of the reference electrodes 5 are respectively provided with outer guide wires 21, 31, 41 and 51, Cl - Probe 2, pH probe 3, steel electrode 4 and MnO 2 The reference ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com