Steel reinforcement corrosion sensor and preparation method and its detection method for reinforcement corrosion

A steel corrosion and sensor technology, applied in the field of sensors, can solve problems such as inability to accurately judge the corrosion state of steel bars, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

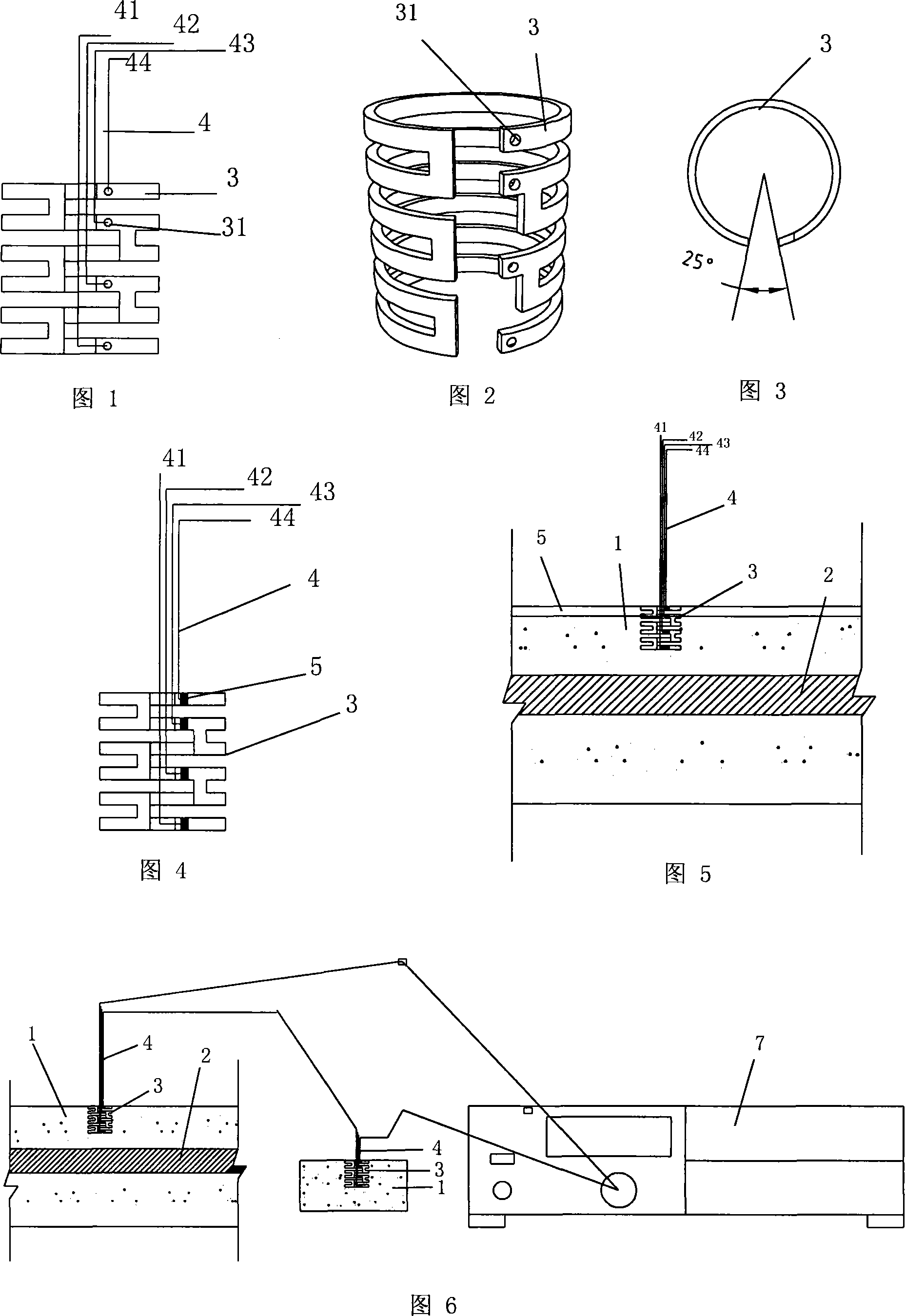

[0032] Referring to Figures 1 to 3, the steel bar corrosion sensor of the present invention is provided with a base body 3 and lead wires 4 (4 lead wires 41 to 44 are established in total), the cross section of the base body is circular, and the base body 3 is a spiral layer in the vertical direction. shape distribution. The thickness of each layer of the base body 3 is 2 mm, the distance between layers is 2 mm, the vertical length of the base body is 20-50 mm, and the number of layers of the base body is 4-10. The outer diameter of the cross-section can be adjusted according to the diameter of the steel bar section. The outer diameter of the general engineering steel bar is mostly in the range of 16-40mm. Therefore, when selecting the steel bar material, it is better to take the outer diameter of the sensor substrate as consistent as possible with the diameter of the steel bar in the component. , the inner diameter is 2mm smaller than the outer diameter. A wire lead-out hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| To the length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com