Migrating type composite rebar corrosion inhibitor as well as preparation method and application thereof

A technology of composite steel bar and rust inhibitor, applied in the field of building materials, can solve the problem that the efficiency is not as obvious as that of the anode type, and achieve the effects of reducing self-corrosion potential and corrosion current density, excellent corrosion and rust inhibition performance, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0045] Examples 1~3 A kind of migratory composite steel bar rust inhibitor

[0046] The raw material composition is shown in Table 1; it is prepared by the following method:

[0047] (1) Heat the sorbitol to 80~100℃ to melt the sorbitol completely and stir evenly;

[0048] (2) Add triethanolamine to it and stir evenly;

[0049] (3) Add boric acid again and increase the temperature to 100~120℃. After the boric acid is completely dissolved, keep it for 1~2h;

[0050] (4) Cool to about 80°C, add deionized water, stir evenly, and add sodium monofluorophosphate until completely dissolved.

[0051] Table 1 Example 1-3 Raw Material Composition

[0052]

Embodiment 4

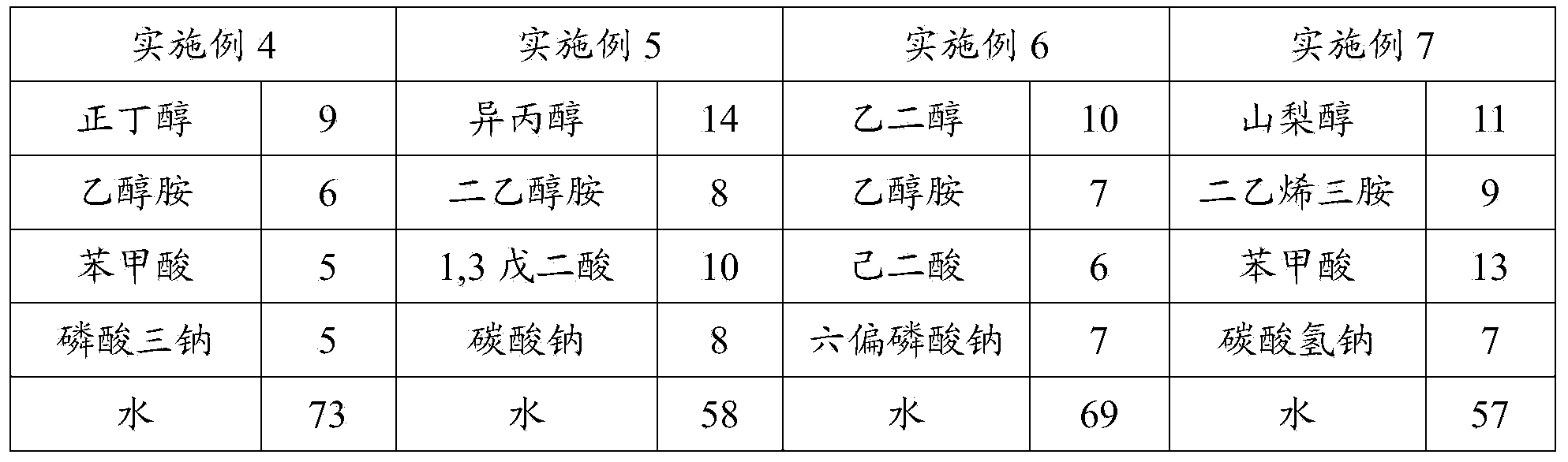

[0067] Example 4 A kind of migratory composite steel bar rust inhibitor

[0068] The composition of raw materials is shown in Table 3; prepared by the following method:

[0069] (1) Heat the n-butanol to 60°C and stir evenly;

[0070] (2) Add ethanolamine to it and stir evenly;

[0071] (3) Add benzoic acid again and increase the temperature to 100°C. After the benzoic acid is completely dissolved, keep it warm for 1.5h;

[0072] (4) Cool to about 80°C, add deionized water, stir evenly, and add trisodium phosphate until completely dissolved.

Embodiment 5

[0073] Example 5 A kind of migratory composite steel bar rust inhibitor

[0074] The composition of raw materials is shown in Table 3; prepared by the following method:

[0075] (1) Heat isopropanol to 70°C and stir evenly;

[0076] (2) Add diethanolamine to it and stir evenly;

[0077] (3) Add 1,3-glutaric acid again, and increase the temperature to 110°C. After the 1,3-glutaric acid is completely dissolved, keep it warm for 2h;

[0078] (4) Cool to about 80°C, add deionized water, stir evenly, and add sodium carbonate until it is completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com