A kind of reinforced concrete rust inhibitor and preparation method thereof

A technology of reinforced concrete and rust inhibitor, which is applied in the field of reinforced concrete rust prevention, can solve the problems of harmfulness to human health, pollution of the environment, and insufficient protection of steel bars, etc., and achieves the effects of easy-to-obtain raw materials, simple preparation process, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

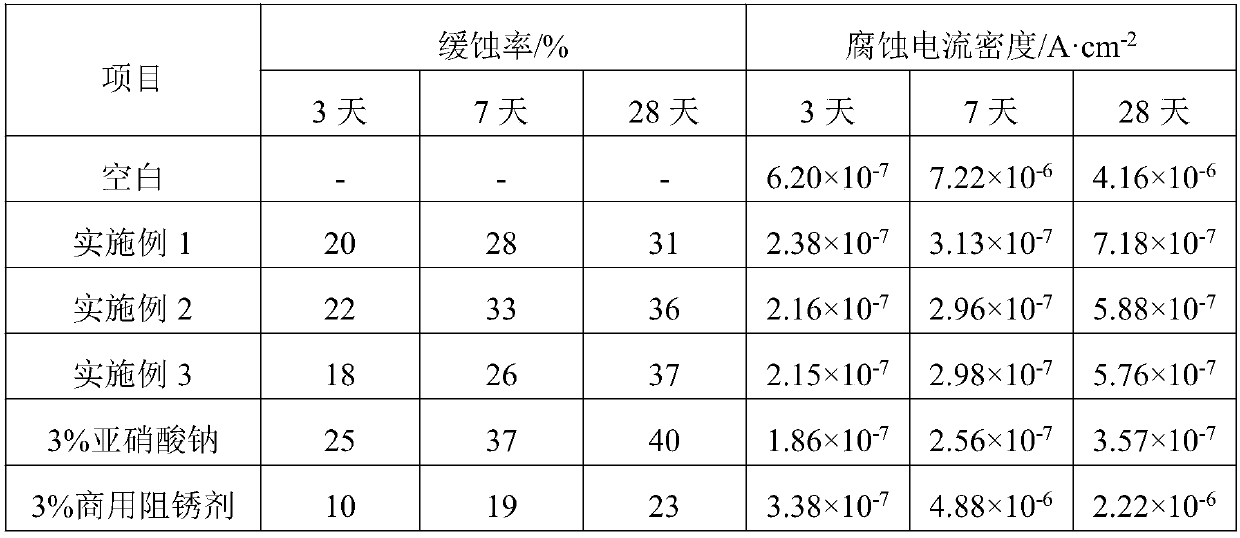

Examples

Embodiment 1

[0024] First, the monomeric ionic liquid 1-vinyl-2-methyl-3-ethylamine-imidazolium cationic amino acid anion salt needs to be prepared according to the following steps:

[0025] Step D1: Preparation of intermediates: dissolving N-vinyl-2-methylimidazole in the second organic solvent to prepare a solution with a mass fraction of 5%, and then adding N-vinyl-2-methylimidazole and N-vinyl-2-methylimidazole equimolar 2-Bromoethylamine hydrobromide, stir and heat at 500r / min and heat up to 60°C, react for 36h, cool to 25°C room temperature after the reaction, vacuum filter, put the filter cake in a drying oven at 50°C Drying under conditions for 24h, to obtain the intermediate;

[0026] Step D2: Dissolve the intermediate obtained in step D1 in dichloromethane to prepare a solution with a mass fraction of 40%, then add sodium hydroxide equimolar to the intermediate, stir and react at 1500r / min, 25°C for 24h at room temperature, and react After cooling to 25°C room temperature, the p...

Embodiment 2

[0036] First, the monomeric ionic liquid 1-vinyl-2-methyl-3-ethylamine-imidazolium cationic amino acid anion salt needs to be prepared according to the following steps:

[0037] Step D1: Preparation of intermediates: dissolving N-vinyl-2-methylimidazole in a second organic solvent to prepare a solution with a mass fraction of 10%, and then adding N-vinyl-2-methylimidazole and N-vinyl-2-methylimidazole equimolar 2-Bromoethylamine hydrobromide, stirring and heating at 1000r / min and heating to 80°C, then reacting for 12 hours, cooling to 25°C room temperature after the reaction, vacuum filtration, putting the filter cake in a drying oven at 80°C Drying for 6h under the condition to obtain the intermediate;

[0038]Step D2: Dissolve the intermediate obtained in step D1 in dichloromethane to prepare a solution with a mass fraction of 50%, then add sodium hydroxide equimolar to the intermediate, stir and react at 2000r / min, 25°C for 12h at room temperature, and react After cooling ...

Embodiment 3

[0048] First, the monomeric ionic liquid 1-vinyl-2-methyl-3-ethylamine-imidazolium cationic amino acid anion salt needs to be prepared according to the following steps:

[0049] Step D1: Preparation of intermediate: Dissolving N-vinyl-2-methylimidazole in a second organic solvent to prepare a solution with a mass fraction of 8%, and then adding N-vinyl-2-methylimidazole and N-vinyl-2-methylimidazole equimolar 2-Bromoethylamine hydrobromide, stirred and heated at 800r / min and heated to 70°C, reacted for 24h, cooled to 25°C room temperature after the reaction, vacuum filtered, put the filter cake in a drying oven at 65°C Drying under conditions for 12h, to obtain the intermediate;

[0050] Step D2: Dissolve the intermediate obtained in step D1 in dichloromethane to prepare a solution with a mass fraction of 50%, then add sodium hydroxide equimolar to the intermediate, stir and react at 1800r / min, 25°C for 12h at room temperature, and react After cooling down to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com