Organic reinforcing steel bar rust inhibitor for reinforced concrete

A steel bar rust inhibitor and organic technology, applied in the field of organic steel bar rust inhibitor, can solve the problems of limited promotion and use, the rust inhibitor is not environmentally friendly, the price of sodium molybdate is expensive, etc., and achieves excellent corrosion and rust inhibition performance and environmental protection. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

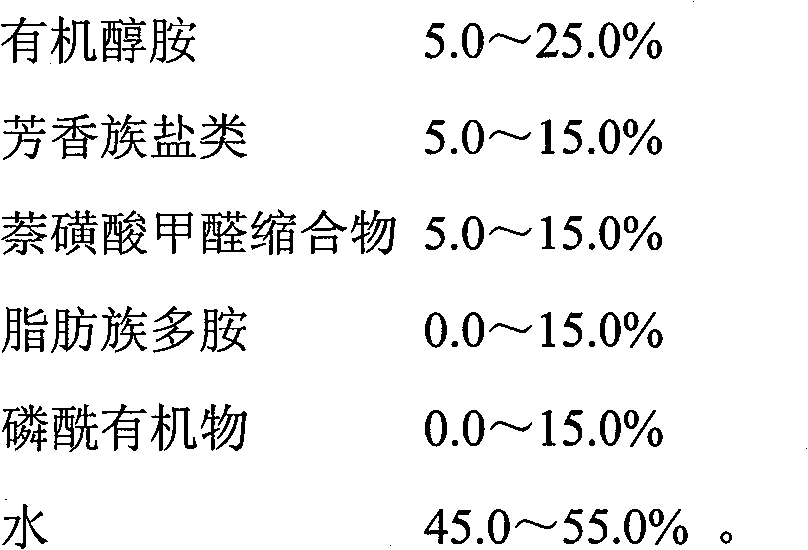

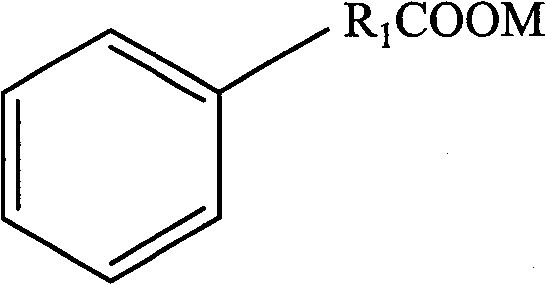

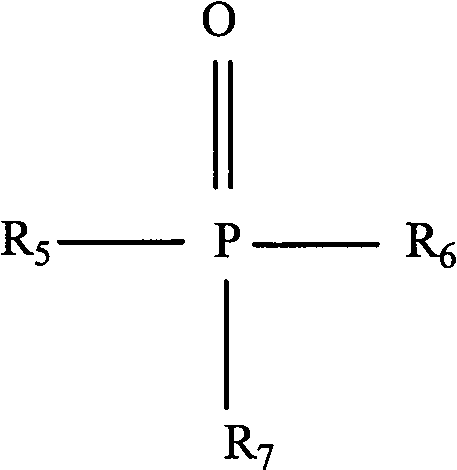

[0023] Weigh 100g of diethanolamine, 150g of N,N-dimethylethanolamine and add it into a glass container, then add 150g of hexamethylphosphoric triamide under stirring; simultaneously weigh 450g of water and add it to the glass container, weigh benzene Sodium formate 50g, naphthalenesulfonic acid formaldehyde condensate 100g, under the state of stirring, successively add into the container of weighing water, fully stir until the solid is uniformly dissolved, then add into the solution prepared in the first step, and stir well to get the resistance rust products.

Embodiment 2

[0025] Weigh 150g of N,N-dimethylethanolamine and add it into a plastic container, then add 50g of N,N-tetramethylenephosphoramide and 100g of triethylenetetramine successively under stirring; at the same time, weigh 550g of water and add it to the glass container In the method, weigh 100g of potassium benzoate and 50g of naphthalenesulfonic acid formaldehyde condensate, and add them into the container of weighed water successively under stirring, and stir well until the solids are uniformly dissolved, then add them into the solution prepared in the first step, and stir After uniformity, the rust inhibitor product is obtained.

Embodiment 3

[0027] Weigh 50g of N,N-diethylethanolamine and add it to a stainless steel container, then add 150g of diethylenetriamine under stirring; at the same time, weigh 500g of water and add it to a stainless steel container, weigh 150g of ammonium benzoate, naphthalenesulfonate formaldehyde Add 150g of the condensate into the container of weighed water one by one while stirring, stir well until the solid is uniformly dissolved, then add it into the solution prepared in the first step, and stir well to get the rust inhibitor product.

[0028] The present invention has a good antirust effect on steel bars in reinforced concrete, and has no adverse effect on the performance of concrete. The performance indicators comply with the "Technical Regulations for the Use of Steel Bar Rust Inhibitors" YB / T 9231. The indicators are shown in Table 2:

[0029] Table 2 performance index of rust inhibitor

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com