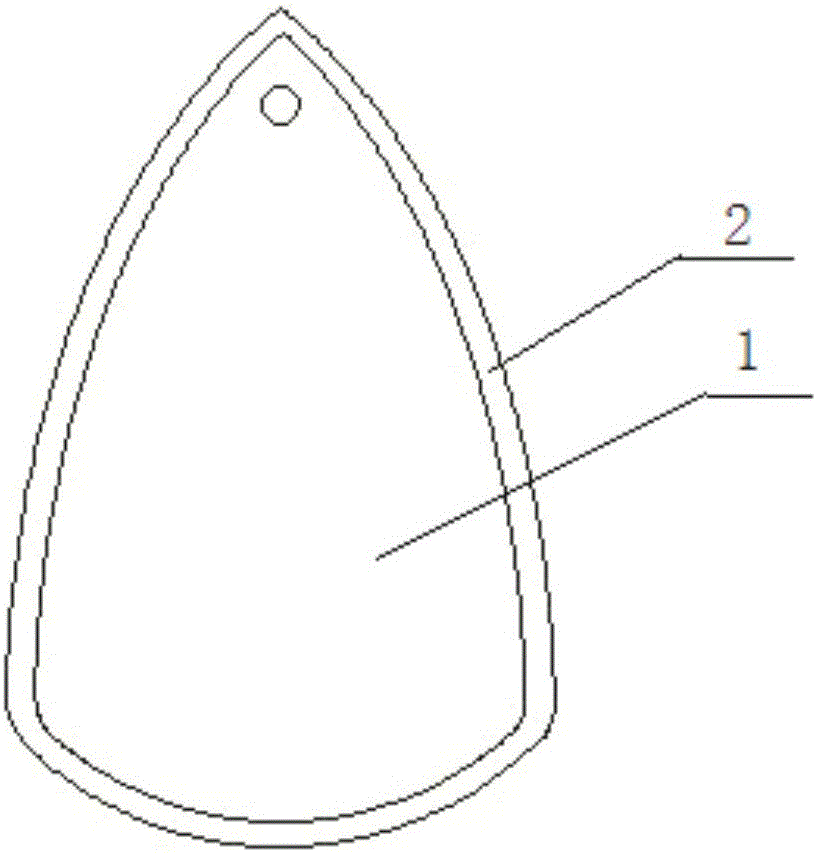

Lead-free fishing plummet and preparing method thereof

A lead-free fishing sinker and fishing sinker technology, applied in the field of fishing sinkers, can solve the problems of lead sinker health and adverse environmental effects, and achieve the effect of excellent appearance grade, excellent anti-corrosion and rust, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also provides a preparation method of a lead-free fishing weight, the preparation method comprising: under the condition of hot-dip galvanizing, contacting the cast iron body with molten zinc, and cooling after the contact; the contact time so that the thickness of the obtained zinc layer is not less than 65 μm; wherein, the cooling includes: cooling the cast iron body after contacting the zinc solution to 200±10°C at a rate of 5-8°C / s, and then cooling at a rate of 10-15°C / s s speed to cool to room temperature (such as 15-35 ℃).

[0021] In the present invention, the above-mentioned cooling can be realized by existing conventional methods, as long as the cooling rate meets the requirements. For example, water cooling is possible.

[0022] The present invention has no special limitation on the conditions of hot-dip galvanizing, which can be conventional choices in this field. For example, the hot-dip galvanizing conditions may include: the temper...

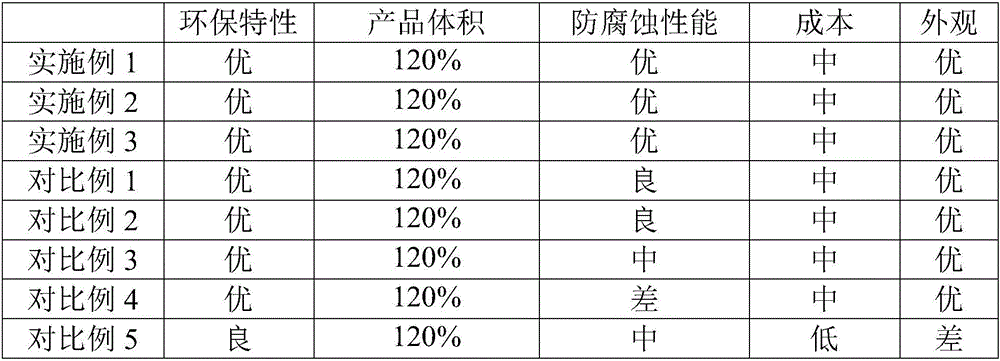

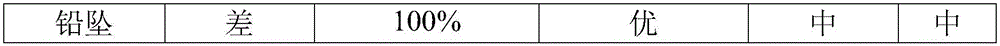

Embodiment 1

[0034] This example is used to illustrate the lead-free fishing weight provided by the present invention and its preparation method

[0035]The cast iron body was pickled and derusted with 5% by weight hydrochloric acid (at a temperature of 25° C. for 10 minutes), and then washed with water to remove acid. Then carry out flux treatment and drying, and the flux treatment is carried out with an aqueous solution of a composite agent consisting of 10% by weight of ammonium chloride and zinc chloride (temperature is 50°C, time is 20s). The obtained cast iron body was contacted with molten zinc at 580°C for 80s. The hot-dipped galvanized cast iron body was water-cooled to 200°C at a rate of 6°C / s, and then water-cooled to room temperature (25°C) at a rate of 10°C / s. Then passivation treatment was carried out on the above-mentioned fishing weight (at a temperature of 25° C. for 3 minutes) to obtain a lead-free fishing weight. Check the obtained fishing weights, the surface is clean...

Embodiment 2

[0037] This example is used to illustrate the lead-free fishing weight provided by the present invention and its preparation method

[0038] The cast iron body was pickled and derusted with 5% by weight of hydrochloric acid (at a temperature of 10° C. for 15 minutes), followed by water washing for deacidification. Then perform flux treatment and drying, and the flux treatment is carried out with an aqueous solution of a composite agent consisting of 15% by weight of ammonium chloride and zinc chloride. The obtained cast iron body was brought into contact with molten zinc at 600°C for 60 s. The hot-dipped galvanized cast iron body was water-cooled to 205°C at a rate of 8°C / s, and then water-cooled to room temperature at a rate of 12°C / s. Then passivation treatment was carried out on the above-mentioned fishing weight (at a temperature of 25° C. for 3 minutes) to obtain a lead-free fishing weight. Check the obtained fishing weights, the surface is clean and smooth, without zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com