Osamine organic rebar corrosion inhibitor and preparation method thereof

A steel rust inhibitor and sugar amine technology, which is applied in the preparation of sugar derivatives, organic chemistry, chemical instruments and methods, etc., can solve the problems of inability to delay corrosion, high application cost, and accelerated dissolution of passivation film, so as to avoid Environmental pollution and ecological damage, excellent anti-rust efficiency, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

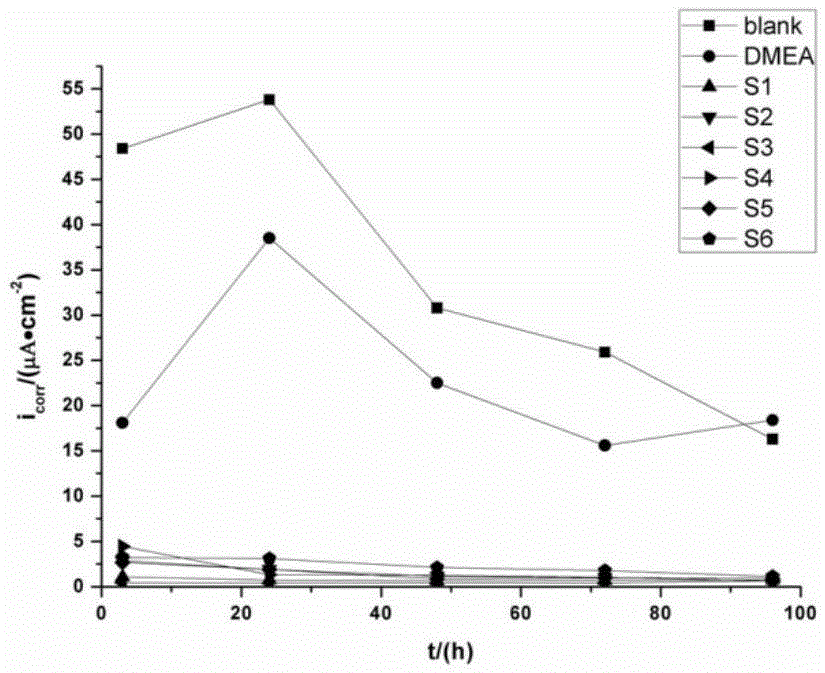

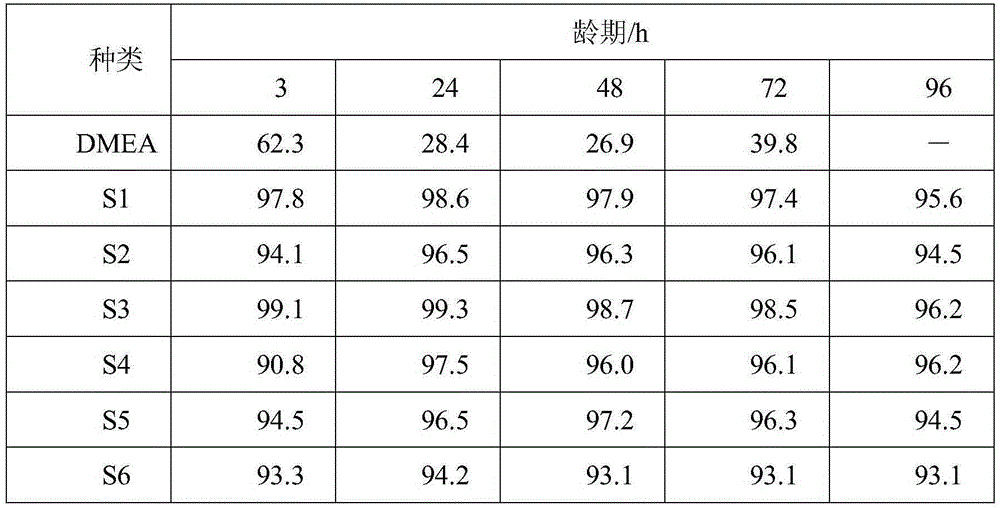

Examples

Embodiment 1

[0027] Add 36g of glucose into a three-necked bottle, then add 80mL of methanol and 21mL of diethanolamine in sequence, react at 50°C for 12 hours under mechanical stirring, cool to room temperature, and spin dry the solvent to obtain the sugar amine organic steel rust inhibitor agent.

Embodiment 2

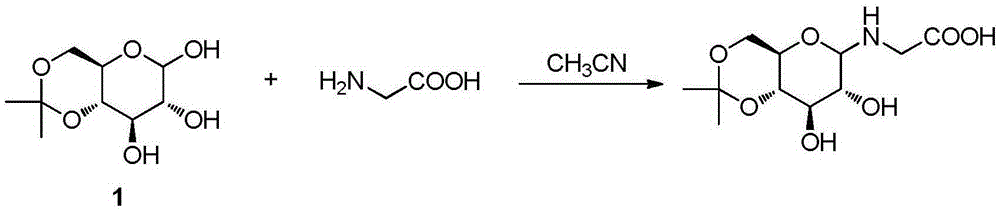

[0029]According to the following reaction steps, add 44g of isopropylidene-protected D-glucopyranose (1) into a three-necked flask, then add 80mL of acetonitrile and 16g of glycine in sequence, react at 80°C for 6 hours under mechanical stirring, and cool to room temperature , and spin dry the solvent to obtain the sugar amine organic steel rust inhibitor.

[0030]

Embodiment 3

[0032] Add 36g of maltose to the three-necked bottle, then add 80mL of 1,4-dioxane and 10mL of aniline in sequence, react at 100°C for 12 hours under mechanical stirring, cool to room temperature, and spin the solvent to obtain the sugar amine Organic steel rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com