On-line corrosion detector for reinforced concrete and method thereof

A technology for reinforced concrete and steel bar corrosion, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems such as difficult to determine the polarization area of steel bars, large deviation of results, far away from the real value, etc., to improve measurement Accuracy, easy operation, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

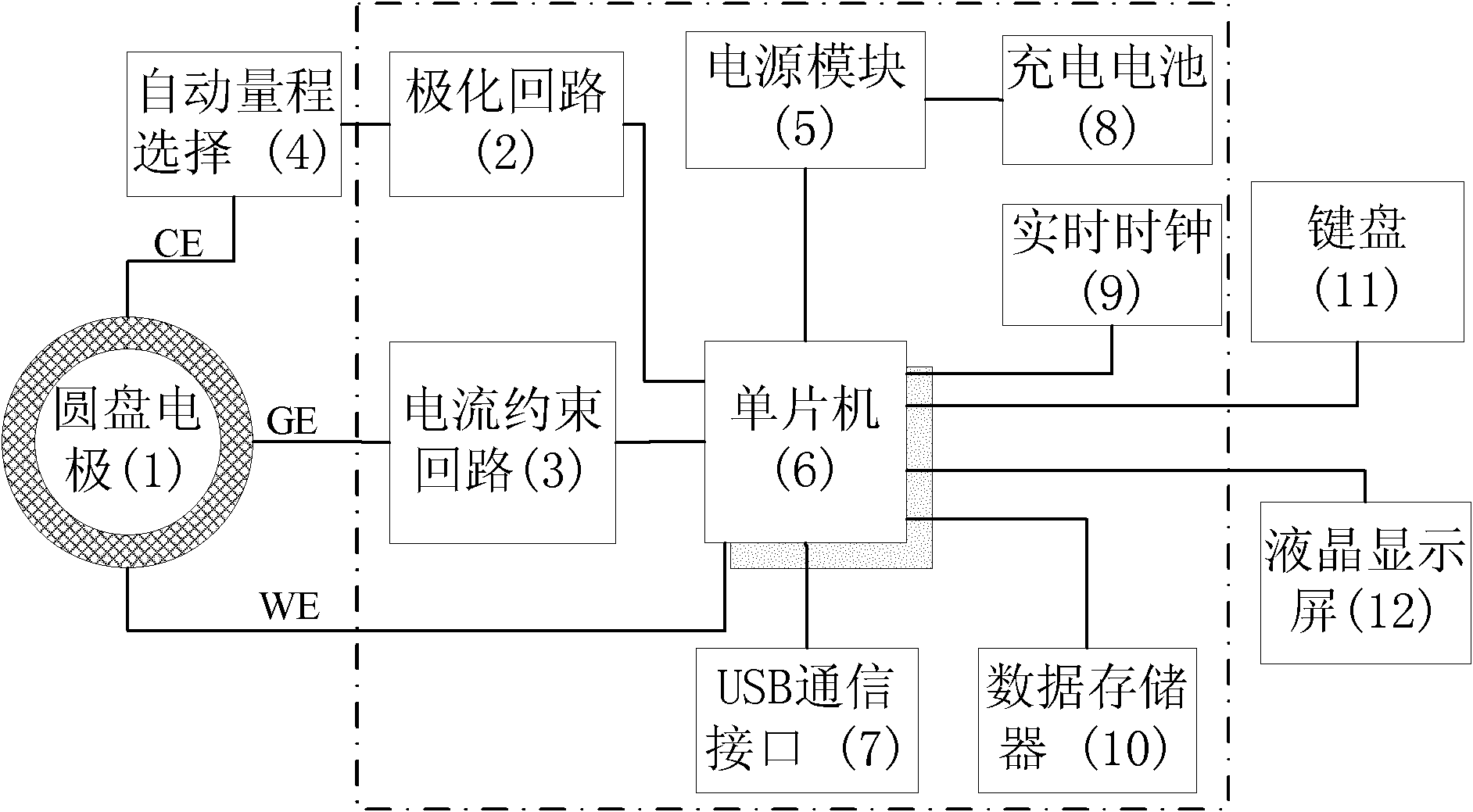

[0025] See attached figure 1 , The on-line detector for reinforced concrete corrosion of the present invention includes: a guard ring disk electrode 1 , a polarization circuit 2 , a current restraint circuit 3 , and a single-chip microcomputer 6 .

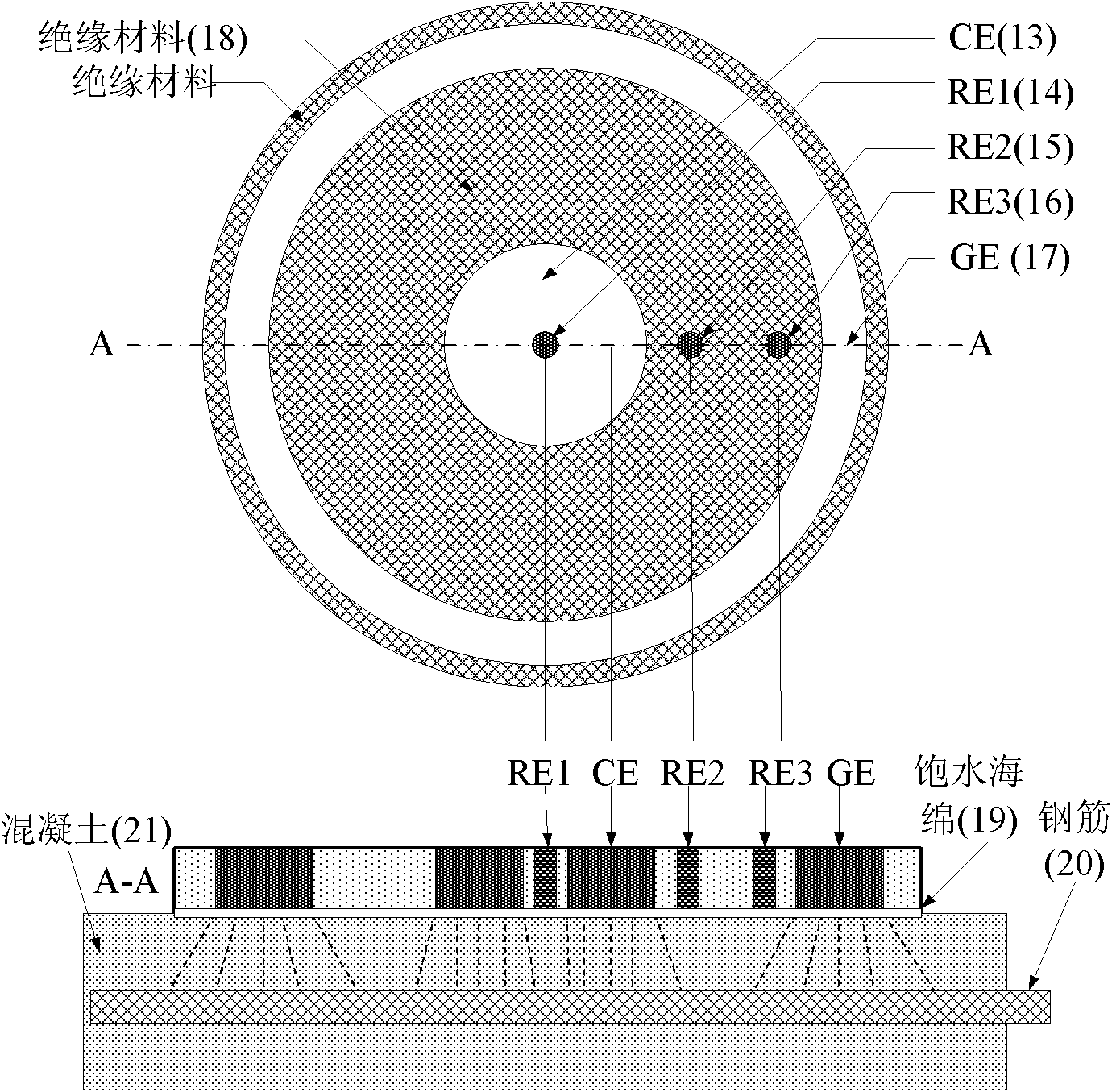

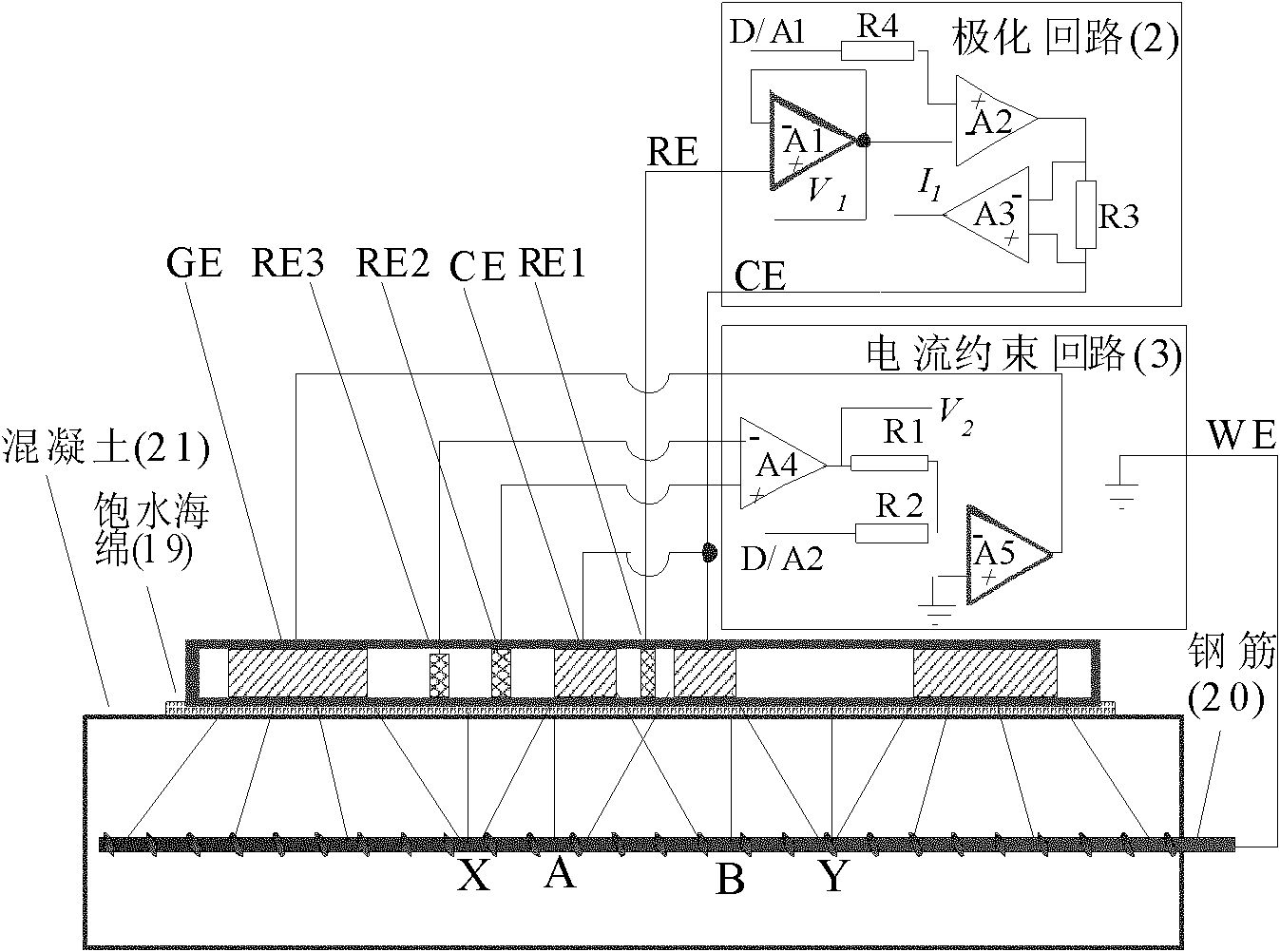

[0026] Such as figure 2 As shown, the guard ring disc electrode is used for the confinement of the polarization current, and the guard ring disc electrode includes 3 reference electrodes RE1, RE2, RE3 (by saturated Cu / CuSO 4 , Ag / AgCl or MnO 2 Electrode composition), an auxiliary electrode CE and a ring electrode GE, CE and GE electrodes are coaxially placed and embedded in an insulating disc, and there is a small hole with a diameter of 1-5mm in the center of the CE electrode for placing the reference electrode RE1 , the two form the input end of the polarization circuit together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com