Non-destructive dynamic monitoring sensor for corrosion of reinforcing steel bar in concrete based on magnetic field and system

A technology for monitoring sensor and steel corrosion, applied in the direction of material magnetic variables, etc., can solve problems such as monitoring systems that do not accurately determine the corrosion rate of steel bars, high requirements for operator proficiency, and inability to quantitatively measure the corrosion rate of steel bars. Easy to operate on site, small size, high precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

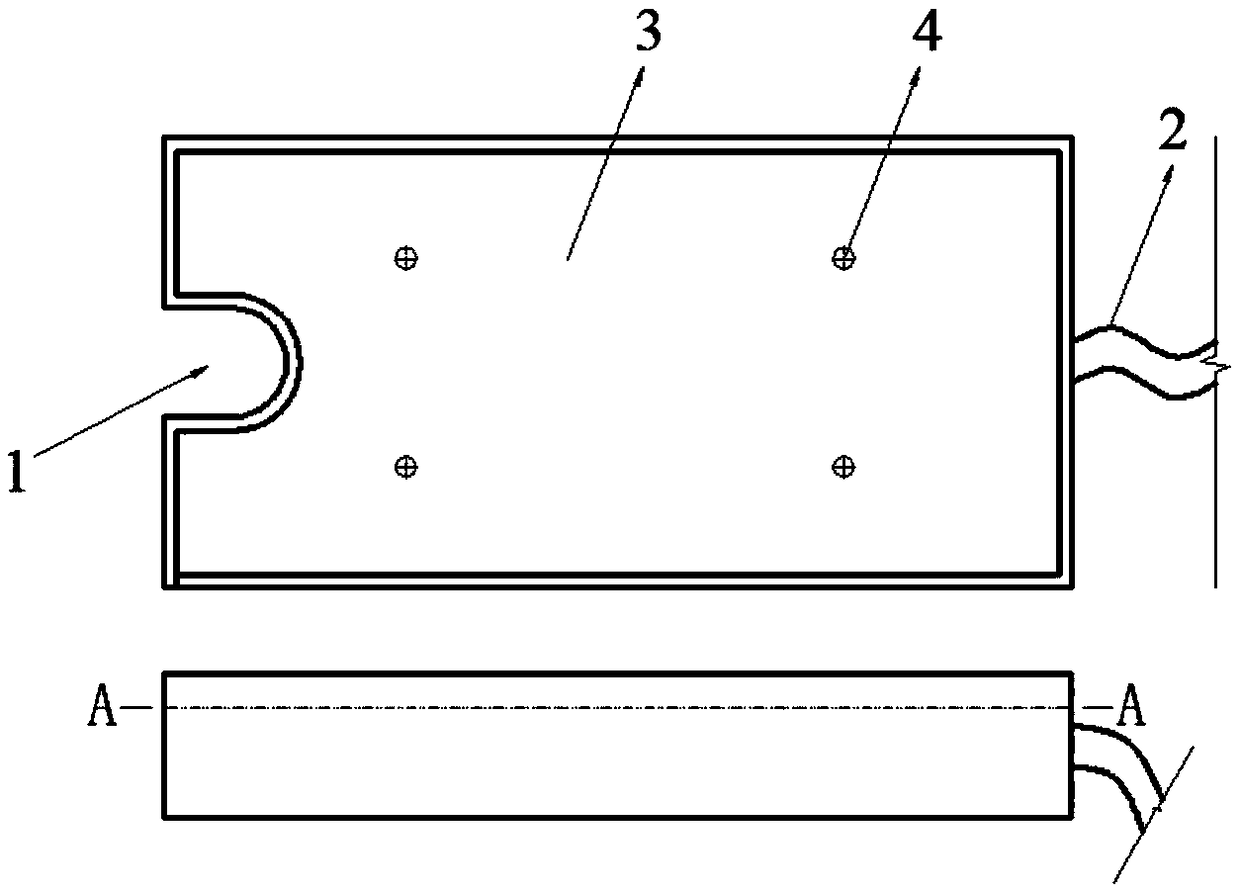

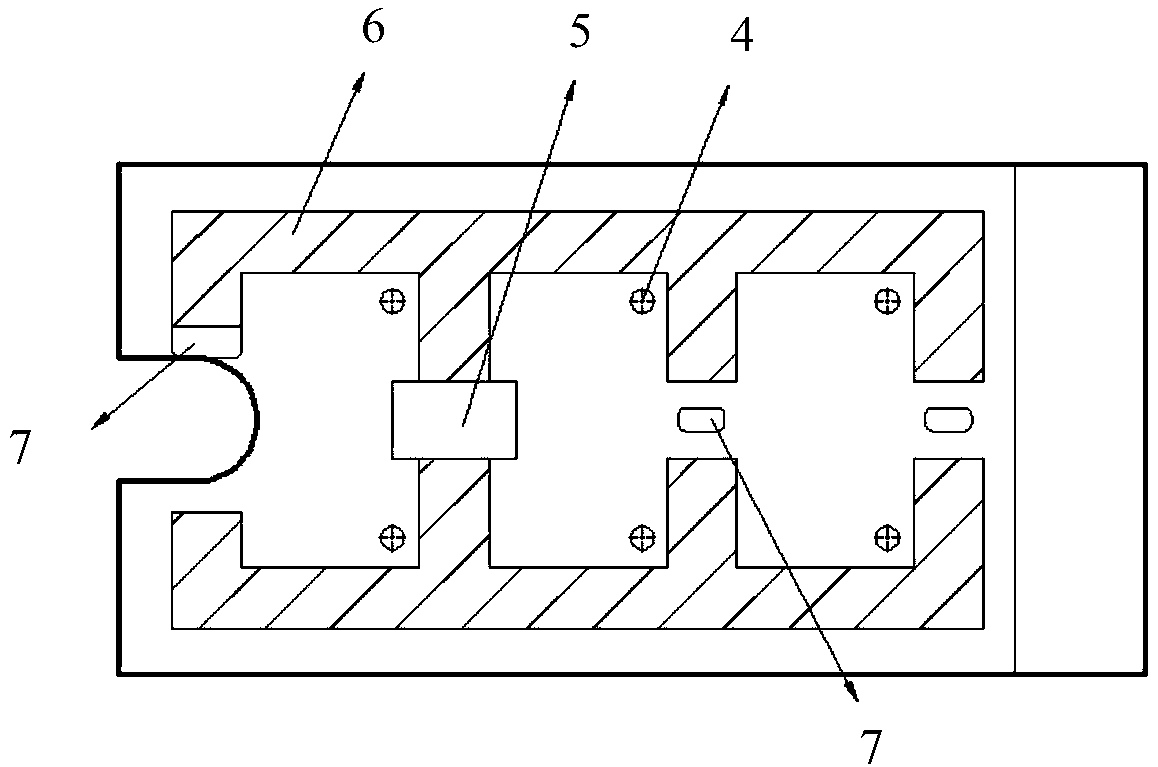

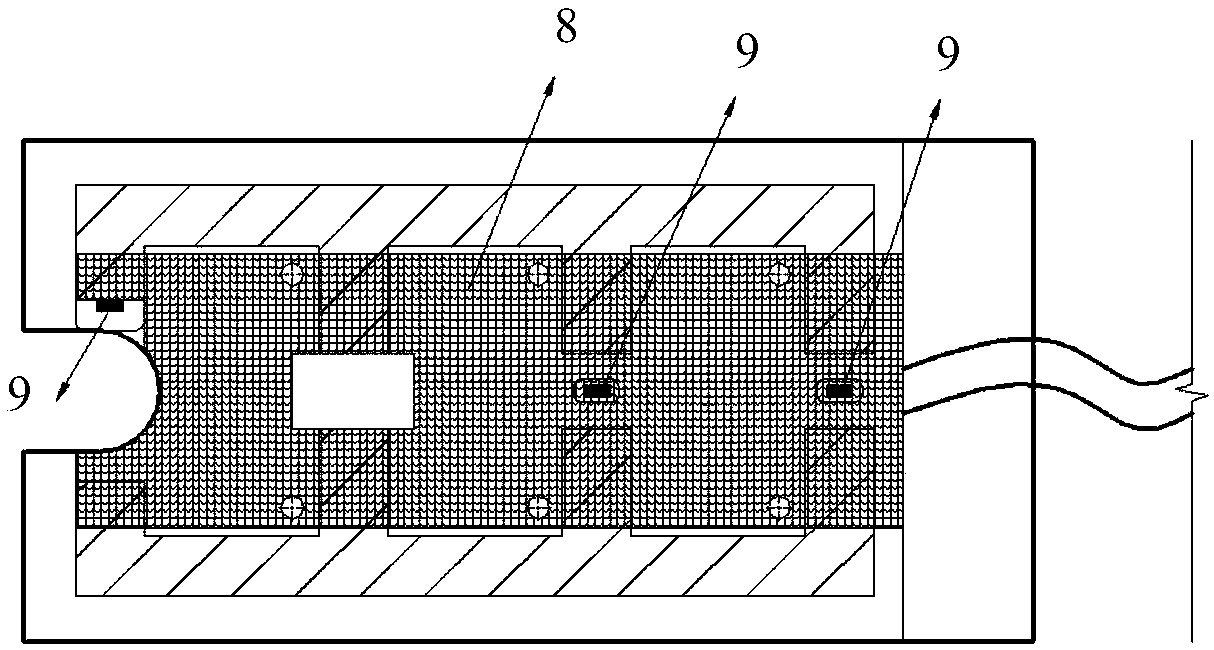

[0034] As shown in the figure, the non-destructive dynamic monitoring sensor for steel bar corrosion in concrete based on the magnetic field includes a hollow box-shaped shell; one end of the shell is provided with a bayonet groove 1 for clamping the steel bar to be tested; there are two in the shell with The stainless steel frame 6 with mountain-shaped protruding teeth and opposite arrangement, except that permanent magnets 5 are arranged between one group of relative teeth, the installation position (card slot 7) of Hall sensor 9 is reserved between other relative teeth, permanent magnet 5 Also fits in a matching card slot. On both sides of the bayonet groove 1, the opposite teeth of the ends of the stainless steel frame 6 and the installation position of a Hall sensor are arranged; there is also a data acquisition board 8 connected to the six-core cable 2 in the housing, and the Hall sensor 9 All are fixed on the data acquisition board 8, and its main body is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com