Sensor device for long-term monitoring of reinforcement corrosion conditions and applied inside concrete

A sensor device, steel corrosion technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of judging the true degree of steel corrosion based on rough and non-quantitative judgments, and can not quantitatively judge steel corrosion. rate and other issues, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

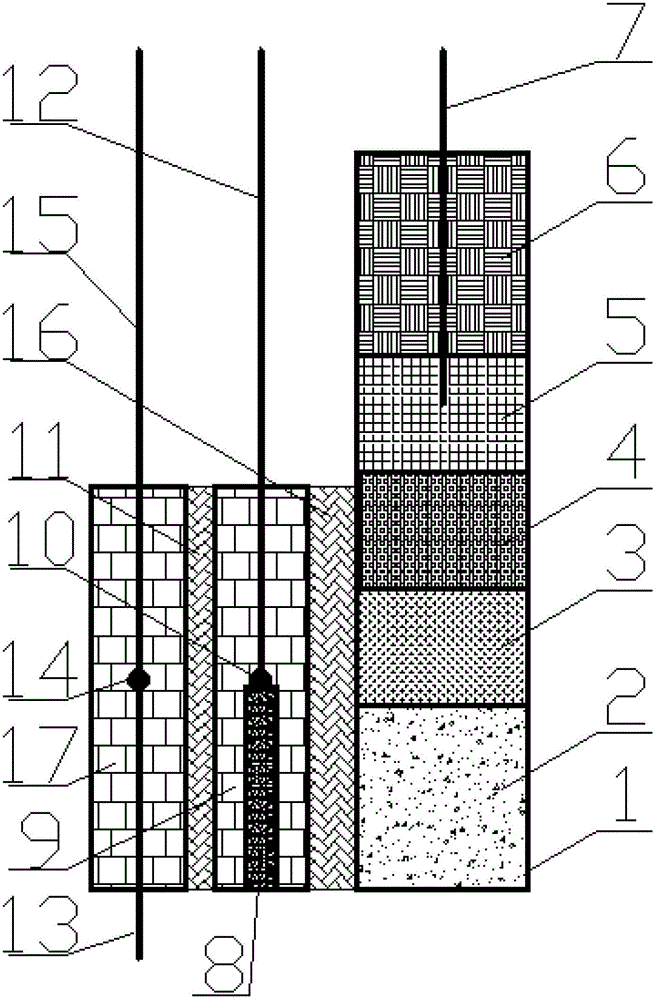

[0019] The present invention as figure 1 As shown, the sensor device used in the long-term monitoring of steel bar corrosion inside the concrete is made of three sensors bonded by the first epoxy resin 11 and the second epoxy resin 16, and one of the sensors is a reference that can be used in concrete components Electrode sensor, reference electrode The sensor is a layered manganese dioxide electrode, and the layered manganese dioxide electrode is arranged in a PVC pipe 1, and the PVC pipe 1 is filled with cement colloid 2 and calcium hydroxide mixed colloid layer in sequence from bottom to top 3. Manganese dioxide colloid layer 4, graphite layer 5 and epoxy resin layer 6, the first copper wire 7 electrically connected to the outside is inserted into the graphite layer 5 through the epoxy resin layer 6 from the top of the PVC pipe 1; the other The sensor is a steel bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com