Piezoelectric sensor for steel-bar corrosion monitoring and steel-bar corrosion monitoring method

A technology of piezoelectric sensors and piezoelectric ceramics, which is applied in the field of piezoelectric sensors and steel corrosion monitoring, can solve problems that have not been reported, and achieve the effects of good reliability, simple calculation, and accurate corrosion status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

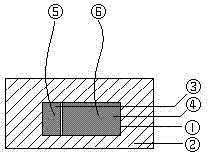

Embodiment 1

[0044] The PZT-5 piezoelectric ceramic with a size of Φ10×1.8mm is used as the sensing element, in which the lower surface electrode of the piezoelectric ceramic extends from the side to the upper surface, and is divided into two parts from the original upper surface electrode. A mixture of ordinary Portland cement, E51 epoxy resin and polyamide curing agent was used as the encapsulation layer, and the copper core RVVP shielded cable was used as the wire to prepare the piezoelectric sensor for steel corrosion monitoring. The preparation process is as follows: first, the shielded cable is respectively welded to the electrode part extending from the lower surface of the piezoelectric ceramic to the upper surface and the original upper surface electrode part of the piezoelectric ceramic; then, the piezoelectric ceramic sheet after welding the wire Fixed in the mold, the welding surface of the ceramic sheet is 3mm away from the inner wall of the mold, the side of the ceramic sheet ...

Embodiment 2

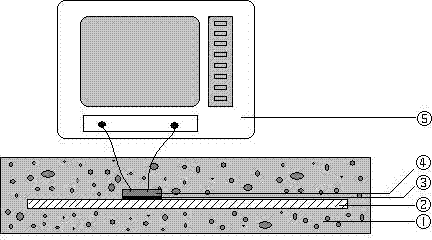

[0046] Make a reinforced concrete rectangular cross-section beam with a strength grade of C30. The size of the beam is length×width×height=500mm×200mm×200mm. The cement is 42.5 grade ordinary Portland cement produced by a certain company, the sand is medium sand with a fineness modulus of 2.5 in a certain real estate, and the crushed stone is continuously graded 5-20mm crushed stone in a certain real estate. The longitudinal tensile steel bars used are Secondary hot rolled ribbed steel bars. First, mix the mixture of cement, epoxy resin and curing agent with a mass ratio of 1:1:0.25, and spread it evenly on the surface of the steel bar and the lower surface of the piezoelectric sensor; then, paste the piezoelectric sensor on the surface of the steel bar, And press to discharge the air and excess adhesive, after curing in the air for 48 hours; fix the steel bars pasted with sensors in the pouring mold, pour concrete raw materials, and demould after standard curing for 24 hours....

Embodiment 3

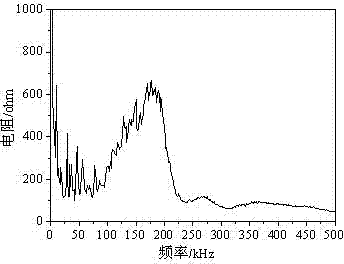

[0048] After the reinforced concrete beam was maintained for 7 days, according to the operation method of embodiment 2, an impedance tester was used to test the resistance-frequency characteristics of the piezoelectric sensor at 50kHz-200kHz, and its resistance-frequency spectrum was as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com