Anti-seismic anti-corrosive prestress pipe pile and manufacturing method thereof

A prestressed pipe pile, anti-corrosion technology, applied in chemical instruments and methods, sheet pile walls, anti-corrosion coatings, etc., can solve the adverse effects of long-term service capacity of pipe piles, limited corrosion resistance of pipe piles, and reduced durability of concrete, etc. problems, to achieve the effect of improving horizontal shear and vertical pull-out performance, excellent seismic performance, and small slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

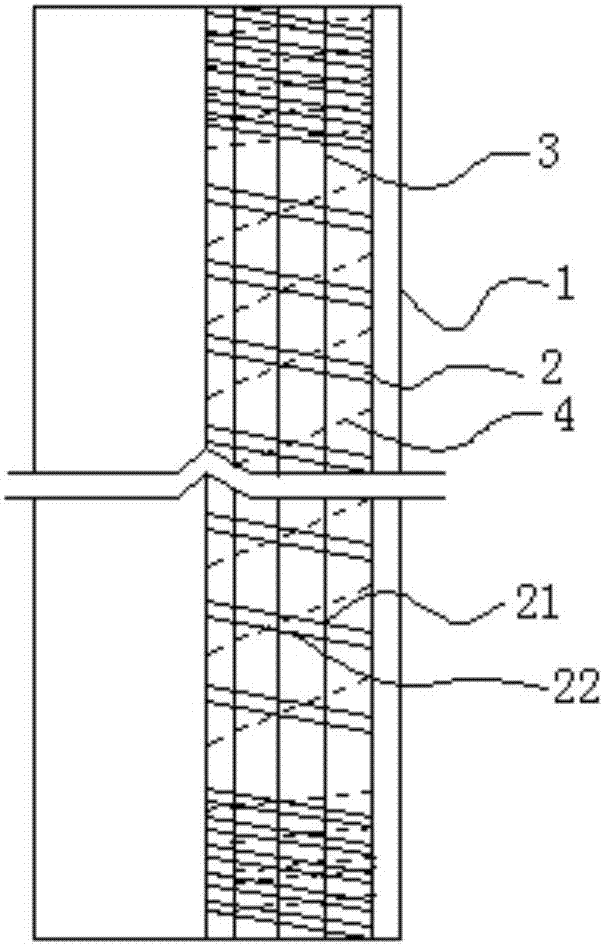

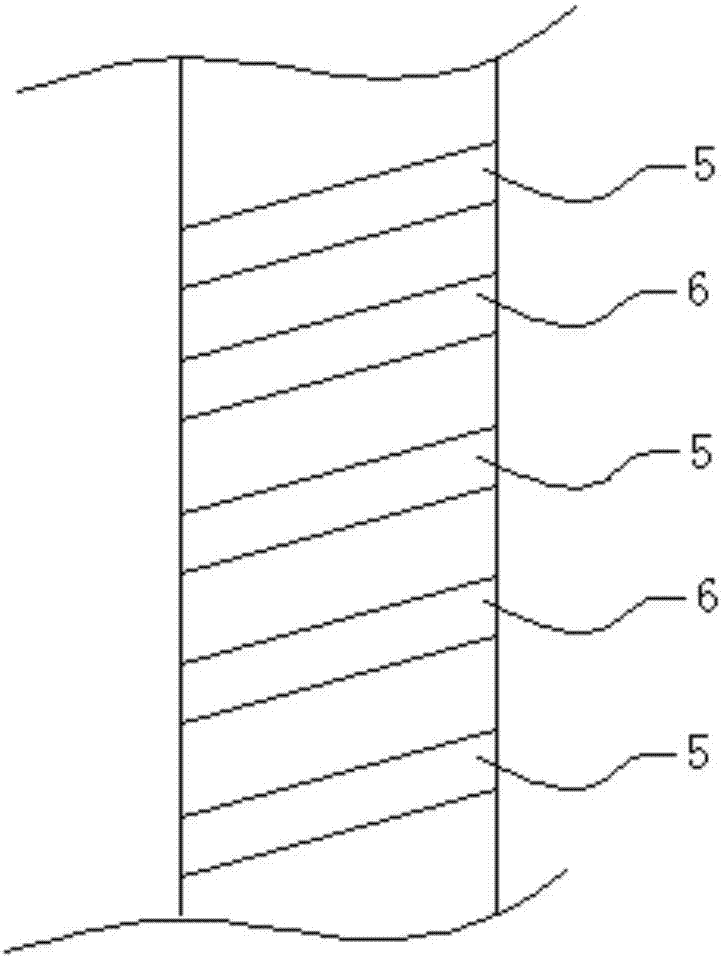

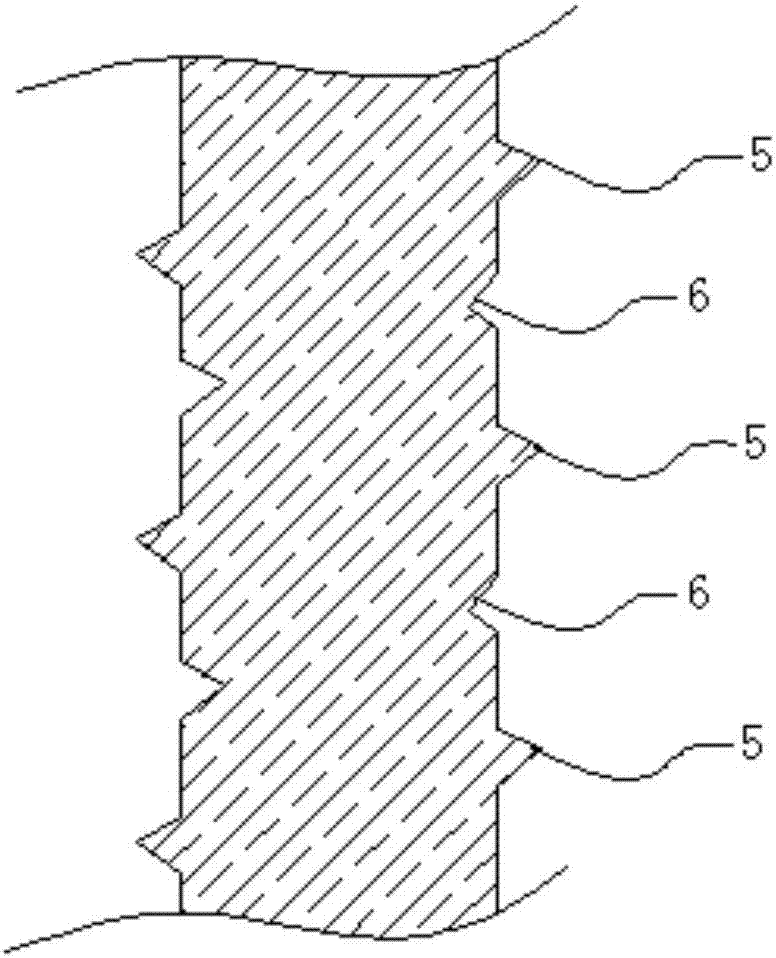

[0041] Embodiment: a kind of anti-seismic corrosion resistant prestressed pipe pile, such as figure 1 , figure 2 with image 3 Shown (dotted line represents circular stirrup), comprises pile body body 1 and reinforcing bar, and described reinforcing bar comprises longitudinal main bar 3, double helix stirrup 2 and annular stirrup 4, and described longitudinal main bar 3, described double helical stirrup 2 and the annular stirrup 4 are all embedded in the pile body 1, the double helix stirrup 2 is wound on the outside of the longitudinal main reinforcement 3, and the annular stirrup 4 is welded to the longitudinal main reinforcement 3 Inside, the helical direction of the double helix stirrup 2 intersects the inclination direction of the annular stirrup 4;

[0042] The double spiral stirrup 2 includes a first spiral stirrup 21 and a second spiral stirrup 22 parallel to each other, the distance between the first spiral stirrup and the second spiral stirrup is 1 / of the outer d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com