High-silicon austenitic stainless steel resistant to concentrated sulfuric acid corrosion and preparing method of high-silicon austenitic stainless steel

A technology of silicon austenite and concentrated sulfuric acid, which is applied in the field of high-silicon austenitic stainless steel and its preparation, can solve the problems of high price, achieve good mechanical properties and welding performance, and improve the effect of high-temperature concentrated sulfuric acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below and through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

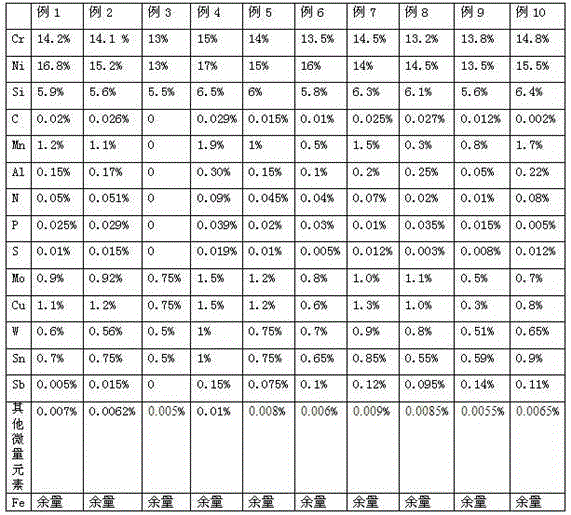

[0040] A high-silicon austenitic stainless steel for concentrated sulfuric acid corrosion resistance, the composition is as follows in terms of weight percentage: Cr: 13-15%, Ni: 13-17%, Si: 5.5-6.5%, C: <0.03%, Mn: <2%, Al: ≤0.30%, N: <0.1%, P: <0.04%, S: <0.02%, Mo: 0.75-1.5%, Cu: 0.75-1.5%, W: 0.5-1%, Sn : 0.5-1%, Sb≤0.15%, other trace elements: 0.005-0.01%, the balance is Fe. Other trace elements are rare earth elements.

[0041] Table 1 shows ten examples of high-silicon austenitic stainless steel for corrosion resistance to concentrated sulfuric acid (the content of each example is in weight percent).

[0042]

[0043] Table 1.

[0044] The high-silicon austenitic stainless steel resistant to concentrated sulfuric acid corrosion of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com