EL sheet and component for lighting type push-button switch

A thin sheet and luminous body technology, applied in the direction of electric switches, light sources, electric light sources, etc., can solve the problems of insulation degradation, luminance reduction, and non-lighting, etc., and achieve the reduction of electrostatic capacity, suppression of insulation degradation, and firm combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

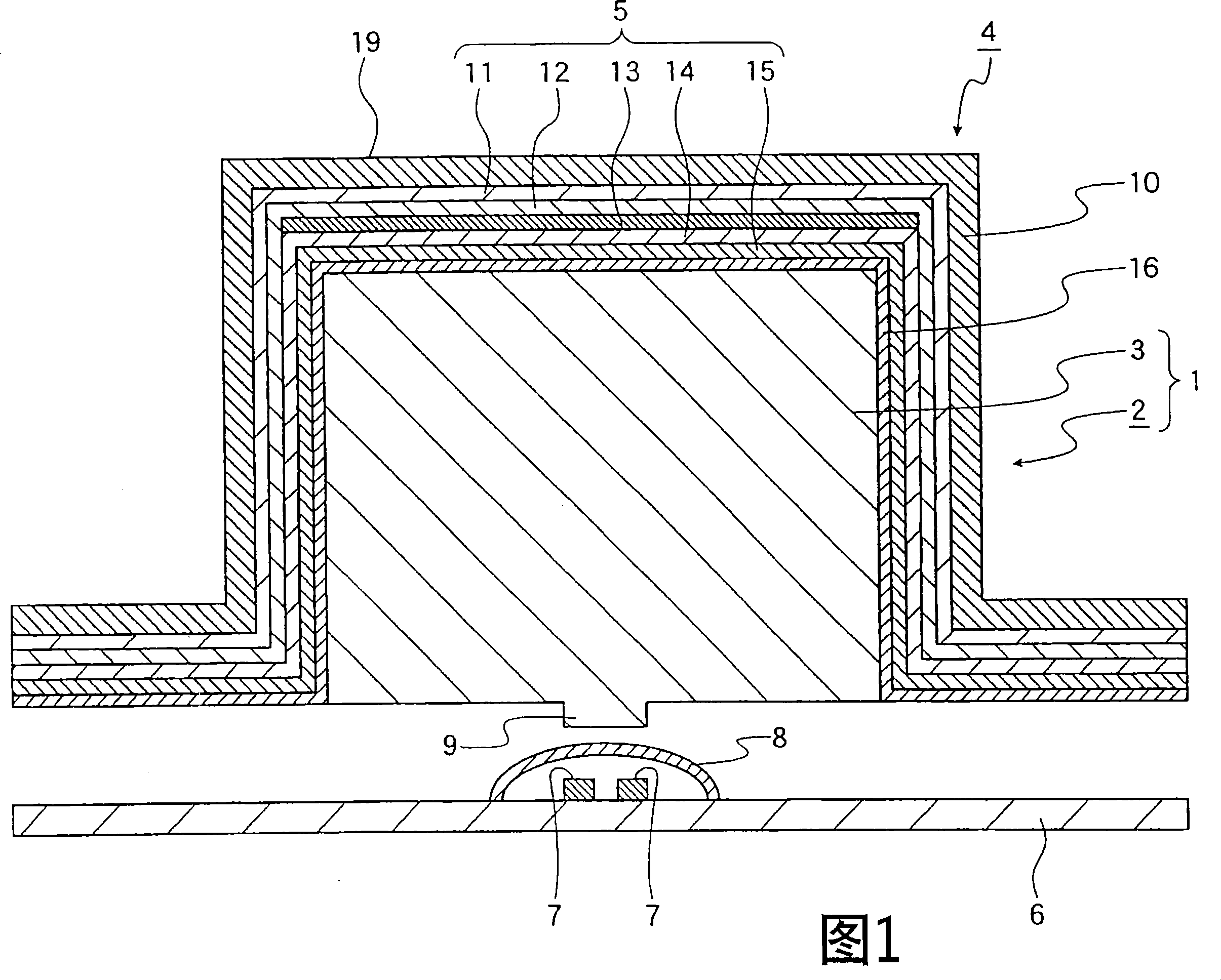

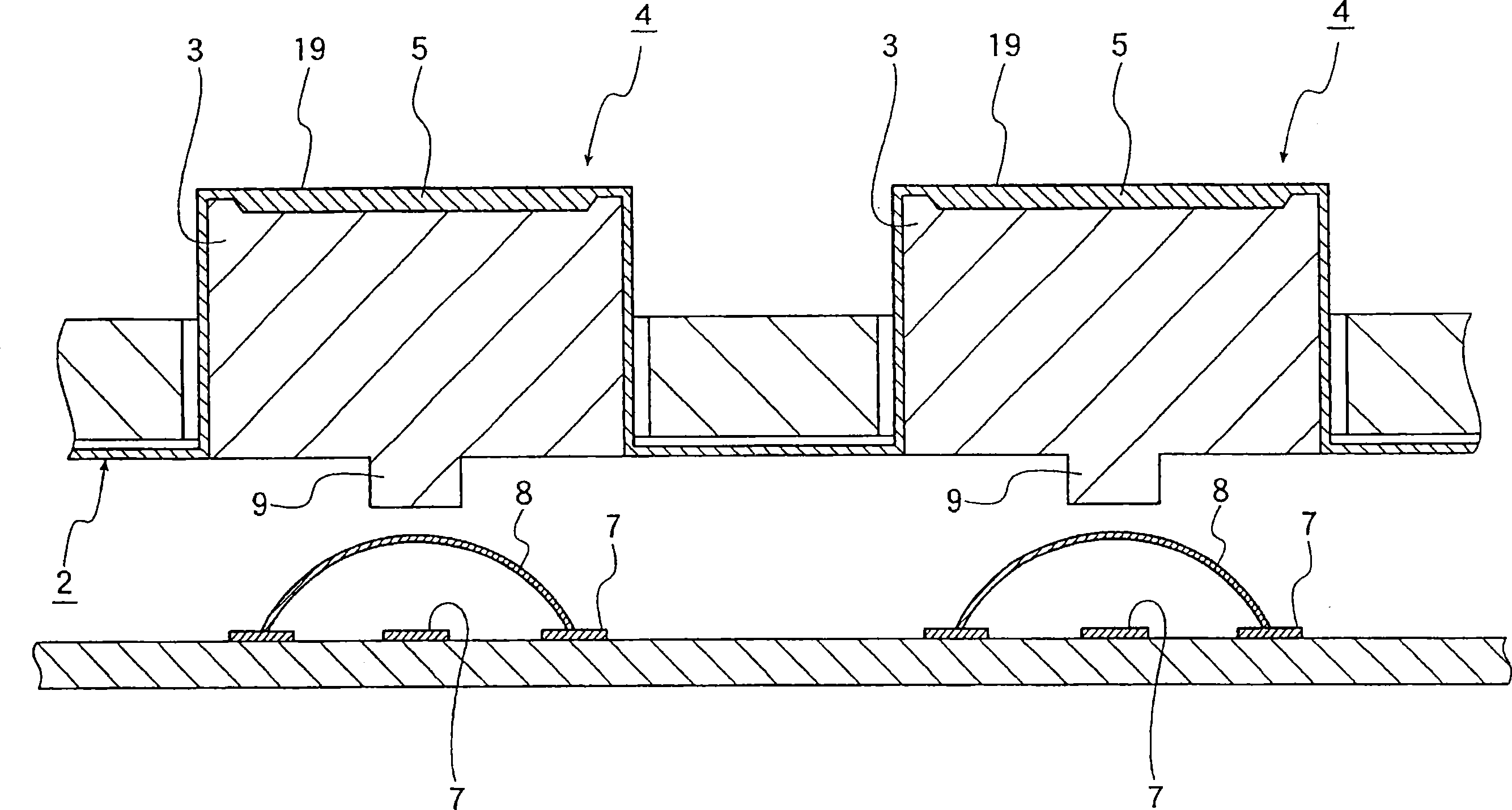

[0106] According to the above-mentioned embodiment, the EL sheet 2 and the member 1 for an illuminated push button switch are formed as follows.

[0107] A polycarbonate-based resin alloy film バイホル (trade name, manufactured by バイエル Corporation) with a thickness of 125 μm is prepared, and it is used as a transparent insulating film 10 on the outermost peripheral surface, and it is applied and colored by screen printing as a decorative layer. ink.

[0108] On the film coated with the colored ink, polyester-based ink IPS-000 (trade name, manufactured by Teikoku Ink Co., Ltd.) was applied by screen printing as a light-transmitting adhesive layer 12, and then a conductive layer 12 was formed by screen printing. A transparent polymer Orgacon P3040 (trade name, manufactured by Agfa Corporation) was used as the transparent electrode layer 11 .

[0109] On the film on which the transparent electrode layer 11 was printed, polyester-based ink IPS-000 (trade name, manufactured by Teikoku...

Embodiment 2

[0117] According to the above-mentioned embodiment, the EL sheet 2 and the member 1 for an illuminated push button switch are formed as follows.

[0118] A 125 μm-thick polycarbonate-based resin alloy film バイホル (trade name, manufactured by バイエル Corporation) was prepared as the transparent insulating film 10 on the outermost peripheral surface, and colored ink was applied thereto by screen printing.

[0119] On the film coated with the colored ink, a conductive polymer Orgacon P3040 (trade name, manufactured by Agfa Corporation) was applied as the transparent electrode layer 11 by screen printing.

[0120] On the thin film printed with the transparent electrode layer 11, the luminescent layer 13 is formed by a wet method at the position where light is required. As the binder, a polyester-based EG-000 Mejumu (trade name, manufactured by Teikoku Ink Co., Ltd.) was used, and EL phosphor GGSS22 (manufactured by Osram Silbania Co., Ltd.) was mixed in the binder at a weight ratio of ...

Embodiment 3

[0127] Barium titanate was dispersed in the fluorine-based resin, and 5% by mass of amphoteric ion-type ion-exchange resin IXE-633 (antimony-bismuth system, trade name, Toagosei Co., Ltd.) was added thereto, and the coating thus obtained was passed through Coating is performed by screen printing as the dielectric layer 14 . Other conditions are identical with embodiment 1.

[0128] Thereby, the member 1 for light-emitting pushbutton switches with high moisture resistance can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com