Etching solution composition and etching method for copper-molybdenum alloy

A technology of copper-molybdenum alloy and etching solution, which is applied in the field of electronic chemicals, can solve the problems of weakened acidity of the etching system, enhanced alkalinity, and high cost of sewage treatment of phosphorus-containing components, and achieve the effect of improving the consumption of organic acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

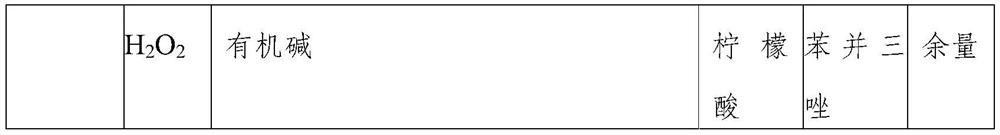

[0032] The composition of embodiment 1-3 and comparative example 1-3 sees the table below, and composition is all in weight percentage in the table:

[0033]

[0034]

[0035] The detection result of embodiment 1-3 and comparative example 1-2 sees the following table:

[0036] Solution life etch tilt angle cd loss Example 1 9500ppm 40.1° 0.85μm Example 2 9800ppm 40.4° 0.80μm Example 3 10000ppm 38.9° 0.88μm Comparative example 1 9400ppm 54.0° 1.09μm Comparative example 2 9700ppm 53.2° 1.05μm

[0037] As can be seen from the above table, Example 3 and Comparative Example 1 form a comparison containing sterically hindered amines in the organic base, and the sterically hindered amines help to reduce the cd loss. In Example 2, all organic bases are sterically hindered amines, and the mass The percentage increases to 6.5%, and the cdloss is further reduced on the basis of Example 1 and Example 3. In contrast...

Embodiment 4-6

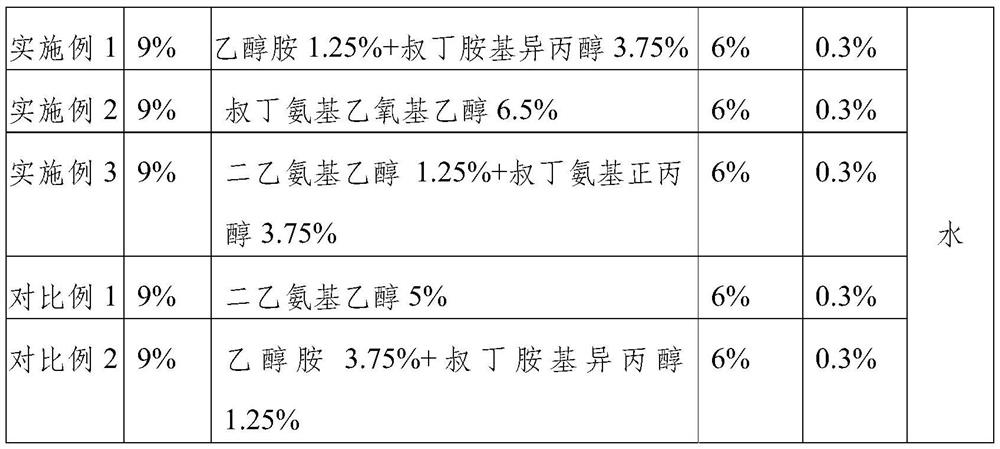

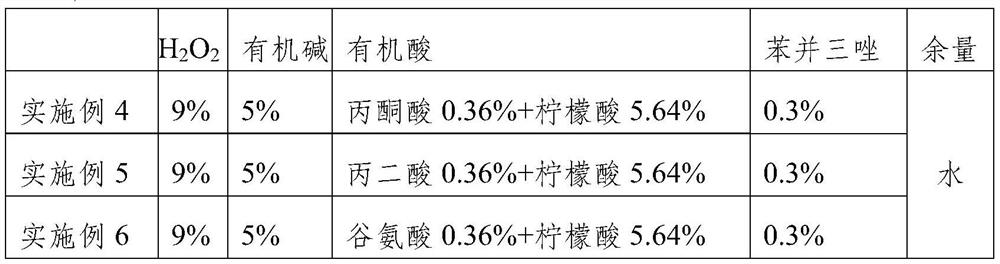

[0039] The composition of embodiment 4-6 and comparative example 3-5 sees the table below, and composition is all in weight percentage in the table:

[0040]

[0041]

[0042] In the above table, H 2 o 2 The weight percent of is calculated as the weight percent of hydrogen peroxide. The difference between embodiment 4-6 and comparative example 3-5 is that the composition of organic acid is different, and organic base all adopts the combination of isopropanolamine and tert-butylaminoethoxyethanol, and the weight of isopropanolamine in the etchant composition Percentage is 1.25%, and the weight percent of tert-butylaminoethoxyethanol is 3.75% (organic base total amount 100%, the weight percent of isopropanolamine is 25%, the weight percent of tert-butylaminoethoxyethanol is 75% %).

[0043] The detection result of embodiment 4-6 and comparative example 3-5 sees the following table:

[0044] Solution life etch tilt angle cd loss Molybdenum layer remains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com