Lithium ion battery

A technology of lithium ion battery and conductive agent, applied in the field of lithium ion battery, can solve the problems of affecting battery storage and high-temperature cycle performance, being unsuitable for the use of negative electrode film-forming additives, serious battery, etc., so as to improve high-temperature storage performance and cycle performance, The effect of reducing the risk of lithium precipitation at low temperature and reducing the interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

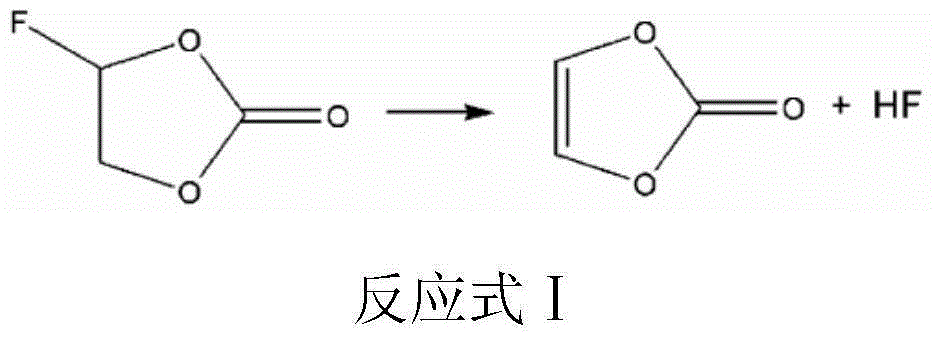

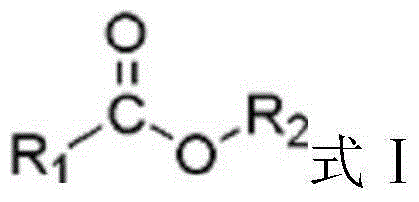

Method used

Image

Examples

Embodiment 1

[0058] Lithium-ion batteries were made according to the method in Comparative Example 3, except for the following differences:

[0059] Add 5% of additive PS and 5% of additive FEC in the non-aqueous electrolyte.

Embodiment 2

[0061] Lithium-ion batteries were prepared according to the method of Example 1, except for the following differences:

[0062] The compacted density of the positive diaphragm is 4.0g / cm 3 ;The compacted density of the negative electrode diaphragm is 1.6g / cm 3 .

Embodiment 3

[0064] Lithium-ion batteries were prepared according to the method of Example 1, except for the following differences:

[0065] The double-sided coating weight of the positive electrode diaphragm is 39.0mg / cm 2 ;The coating weight on both sides of the negative electrode diaphragm is 19.3mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com