Preparation method of S-C positive pole composite material of high cycle performance lithium sulfur battery

A technology of cycle performance and composite materials, applied in the field of electrochemical cells, can solve the problems of complex nano-carbon production method, long sulfur-carbon composite time, poor cycle performance, etc., and reduce self-discharge and polysulfide ion shuttle effect. , The effect of high product performance consistency and small change in sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

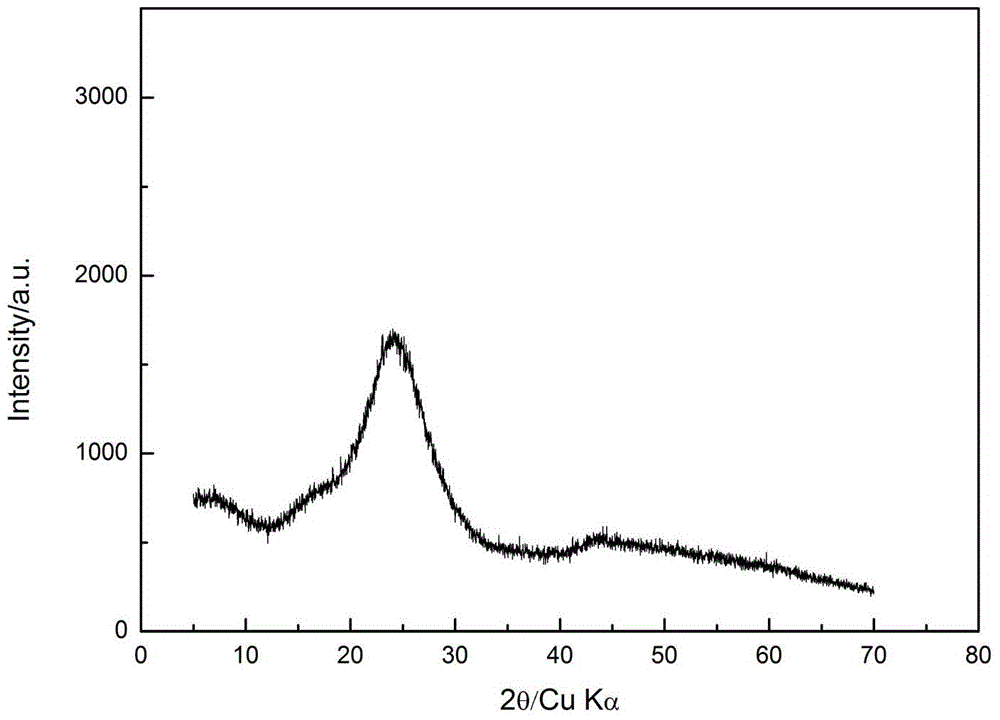

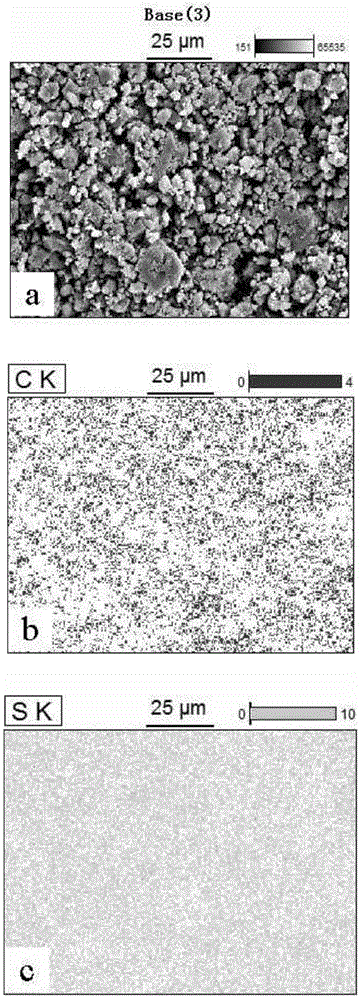

[0024] Weigh 1.4g of sublimed sulfur and 0.6g of Ketjen black conductive carbon black, put them in a ball milling tank, add agate balls, and ball mill on a ball mill at a speed of 250r / min for 10 hours to obtain a uniformly mixed S-C composite powder. Then put the ball-milled SC composite powder on the rotating table of the microwave oven, evacuated and vented with nitrogen gas, controlled the rotating table speed to be 4.5r / min, the heating rate to 18℃ / min, and keep it at 149℃ for 120s, microwave The output power is 2.4kW, and the SC microwave composite material with a sulfur content of 55.53wt% is obtained. Using N-methylpyrrolidone as the organic solvent, the prepared S-C microwave composite material, acetylene black and PVDF were slurried at a mass ratio of 7:1:2. Finally, the adjusted slurry was evenly coated on the aluminum sheet and placed in a vacuum drying oven at 60°C for 12 hours. figure 1 It is the XRD pattern of the obtained sample. It can be seen from the figure t...

Embodiment 2

[0026] Weigh 1.6 g of sublimed sulfur and 0.4 g of acetylene black, put them in a ball mill tank, add agate balls, and ball mill on a ball mill at a speed of 300 r / min for 8 hours to obtain a uniformly mixed S-C composite powder. Then put the ball-milled SC composite powder on the rotating table of the microwave oven, evacuated and ventilate argon gas, control the rotating table speed to 4r / min, the heating rate to 15℃ / min, heat preservation at 125℃ for 150s, microwave The output power is 2.0kW, and the SC microwave composite material with a sulfur content of 59.26wt% is obtained. Figure 4 It is the XRD pattern of the obtained sample, which can be seen from the figure, and also shows the existence of crystalline and amorphous sulfur without any impurity phase. Using deionized water as the solvent, the prepared S-C microwave composite material, Ketjen black conductive carbon black, and LA133 were slurried at a mass ratio of 7:2:1. Finally, the adjusted slurry was evenly coated...

Embodiment 3

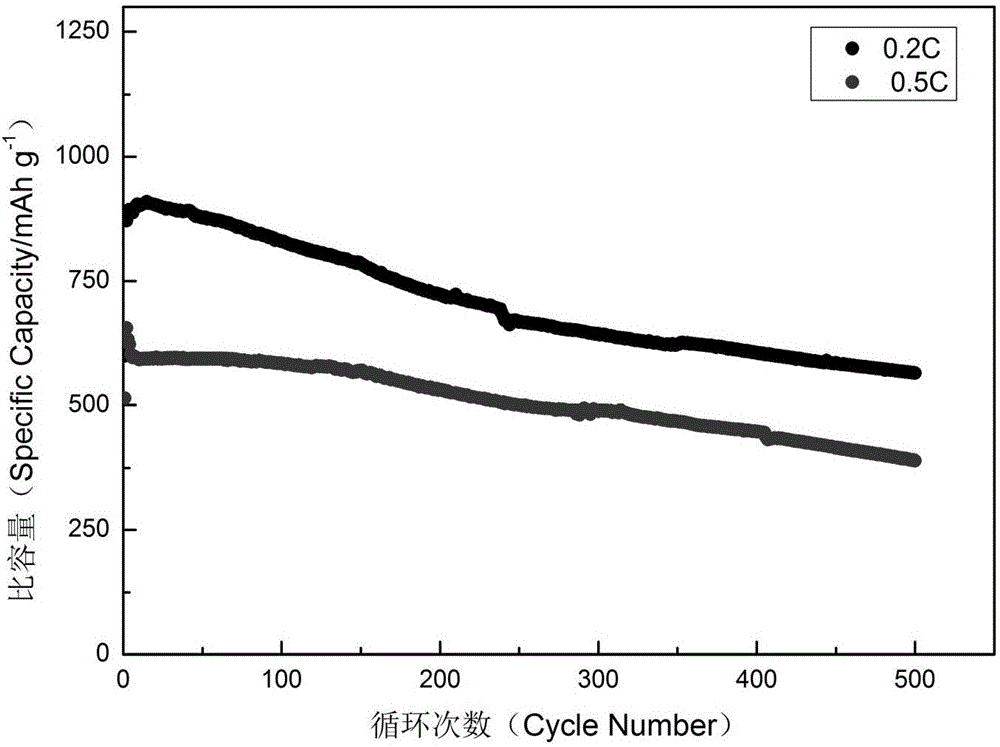

[0028] Weigh 1.2g of sublimed sulfur and 0.8g of BP2000 conductive carbon black, put them in a ball milling tank, add agate balls, and ball mill on a ball mill at a speed of 400r / min for 5 hours to obtain a uniformly mixed S-C composite powder. Then place the ball-milled SC composite powder on the rotating table of the microwave oven, evacuated and blow in nitrogen gas, control the rotating table speed to 5r / min, heating rate to 25℃ / min, heat preservation at 170℃ for 90s, microwave output power It is 2.8kW, and the SC microwave composite material with a sulfur content of 48.11wt% is obtained. Using acetone as the organic solvent, the prepared S-C microwave composite material, BP2000 conductive carbon black and PVDF were slurried at a mass ratio of 7:1.5:1.5. Finally, the adjusted slurry was evenly coated on the aluminum sheet and placed in a vacuum drying oven at 65°C for 10 hours. Using this material as the positive electrode and the metal lithium sheet as the negative electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com