Premixed concrete produced by tailings

A technology of ready-mixed concrete and concrete, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as environmental pollution of waste tailings, achieve extended service life, improve carbonation resistance, reduce Effects on management and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

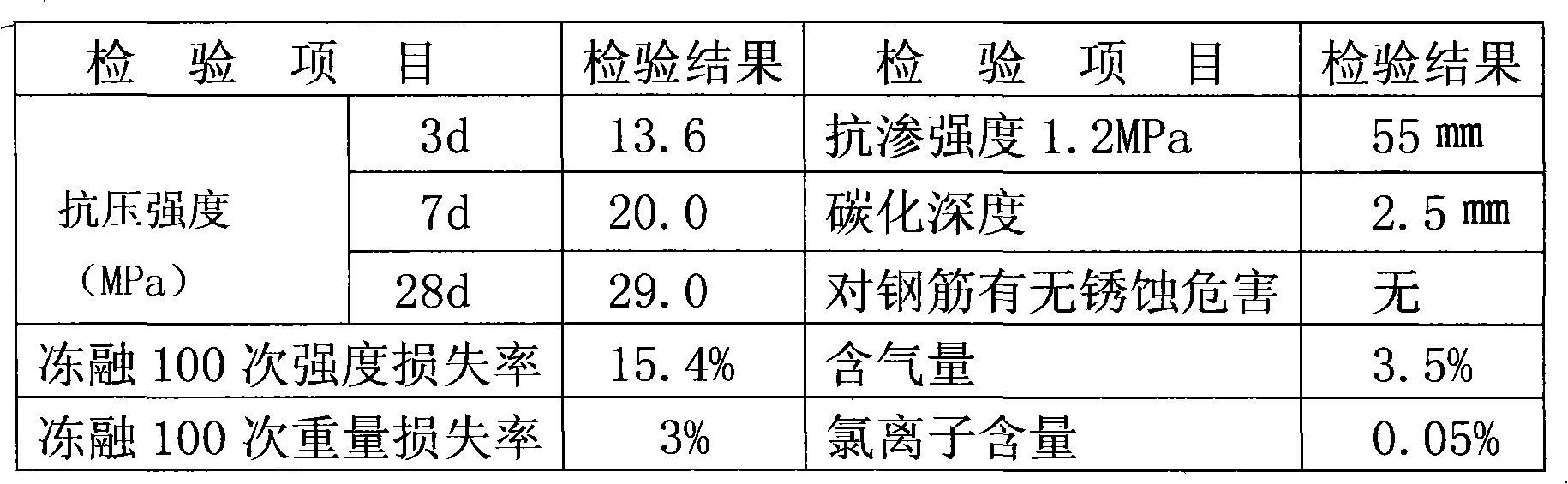

Image

Examples

Embodiment Construction

[0020] The present invention utilizes the tailings to produce the ready-mixed concrete in this way, which will be described in detail below.

[0021] The present invention utilizes tailings to produce ready-mixed concrete, and utilizes waste tailings from mine dressing to produce tailings concrete with a strength level below C35. Waste tailings are used as a component of ready-mixed concrete, and its raw material composition is: PS32. 5 Cement, Class III fly ash, river sand, gravel, tailings powder, water and tailings modifier; of which:

[0022] (1) The slump of C35 tailings concrete out of the mixer is 25cm, and the formula is: PS32.5 cement 330~350kg, grade III fly ash 90~120kg, river sand 700~800kg, crushed stone 780~880kg, 180-300kg of tailings powder, 170-180kg of water and 9.2-9.8kg of tailings modifier;

[0023] (2) The slump of C30 tailings concrete out of the mixer is 25cm, and the formula is: PS32.5 cement 290~310kg, grade III fly ash 90~120kg, river sand 720~820kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com