Method for preparing viscosity-reduction-type polycarboxylic acid superplasticizer and application of viscosity-reduction-type polycarboxylic acid superplasticizer

A viscous polycarboxylic acid and superplasticizer technology, applied in the field of concrete admixtures, can solve the problems of long emptying time, limited viscosity reduction effect, and difficulty in meeting the requirements of high and ultra-high-strength concrete for low-viscosity construction performance, etc. To achieve the effect of reducing the water-to-binder ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

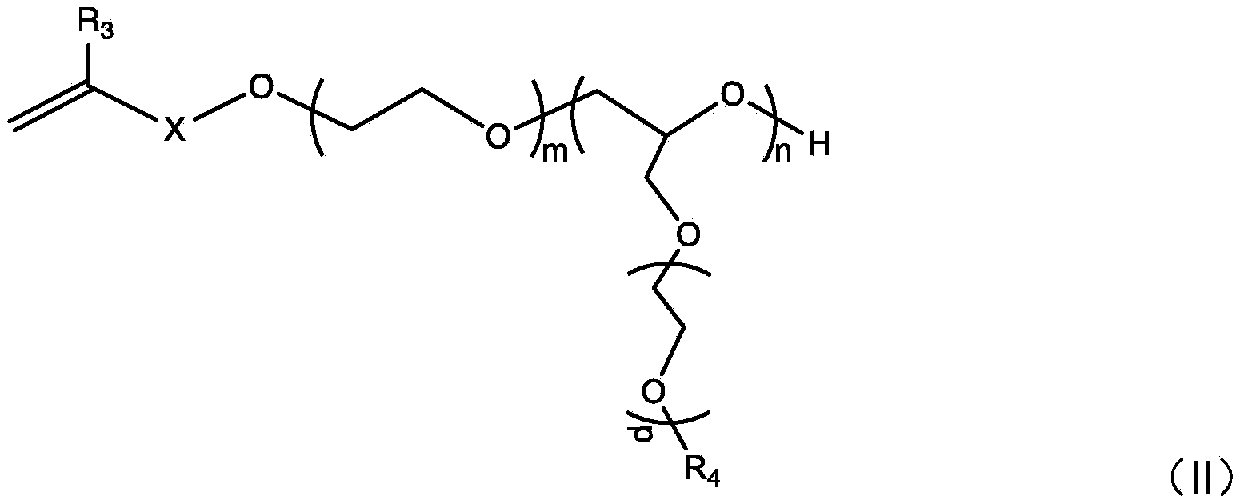

[0041] Preparation of monomer b

[0042] Preparation of epoxy-terminated alkyl polyethylene glycol:

[0043] Add 0.5 mol of epichlorohydrin, 0.2 mol of sodium hydroxide, 0.005 mol of phase transfer catalyst tetra-n-butyl ammonium bisulfate, and 0.05 mol of monoalkyl polyethylene glycol in a stirred three-necked flask. Quickly stirred for 5h, filtered, and the filtrate was distilled under reduced pressure to remove excess epichlorohydrin, and the product was tested by HPLC. The conversion rate of monoalkyl polyethylene glycol was 85% to 90%, and the product was then purified by silica gel column chromatography (acetic acid ethyl ester as eluent) for separation and purification to obtain epoxy-terminated alkyl polyethylene glycol with a purity greater than 99%.

[0044] Summary of epoxy-terminated alkyl polyethylene glycol prepared in table 1

[0045] the code

name

End group type

p

molecular weight

E-1

Epoxy terminated methyl polyethylene gl...

Embodiment 1

[0059] In this example, the molar ratio of monomer a, monomer b and monomer c is 4:1:0.5.

[0060] In a 1 L glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen line, 191 g of distilled water and 286.5 g of monomer b-1 were added. Under the protection of nitrogen, the reactor was stirred until it was completely dissolved, and the temperature was raised to 80°C, then 51.63g of acrylic acid, 9.95g of N-vinylpyrrolidone, 0.35g of 3-mercaptopropionic acid and 67g of water were mixed and stirred to form a uniform monomer aqueous solution , and drop it into the reactor at a constant speed, and the dropping time is 5h. At the same time, the initiator solution mixed with 0.35 g of ammonium persulfate and 86 g of water was added dropwise at a constant speed for 5 hours. After the whole solution was added dropwise, continue to keep the constant temperature for 4h, then cool down to 40°C, neutralize the product to about pH=7 with sodium hydroxide, and o...

Embodiment 2

[0062] In this example, the molar ratio of monomer a, monomer b and monomer c is 6.7:1:1.85.

[0063] In a 1 L glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen line, 164 g of distilled water and 245.5 g of monomer b-2 were charged. Under the protection of nitrogen, the reactor was stirred until it was completely dissolved, and the temperature was raised to 75°C, then 28.07g of acrylic acid, 9.14g of sodium methacrylate, 13.77g of 4-vinylpyridine, 0.59g of mercaptoethanol and 87g of water were mixed and stirred to form Uniform monomer aqueous solution was added dropwise to the reactor at a constant speed, and the dropping time was 4 hours. At the same time, the initiator solution mixed with 1.48g of potassium persulfate and 105g of water was added dropwise at a constant speed for 4 hours. After the entire solution was added dropwise, continue to keep the constant temperature for 3 hours, then cool down to 40° C., and neutralize the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com