Sea sand anti-corrosion marine concrete and preparation method thereof

A technology of concrete and sea sand, applied in the field of building materials, can solve problems such as service life not reaching the designed service life, gel strength degradation, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

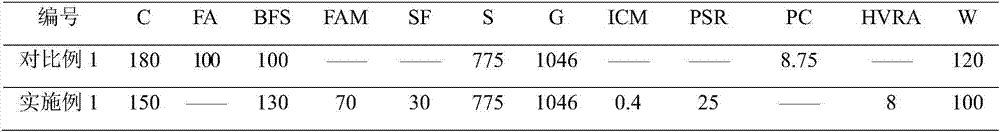

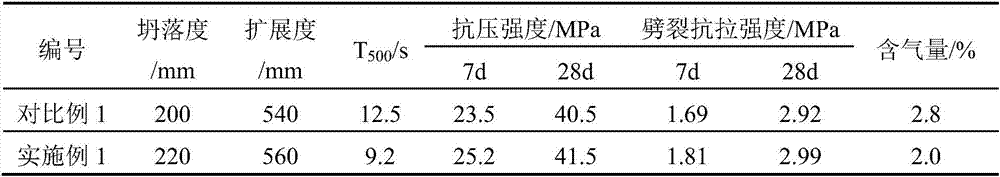

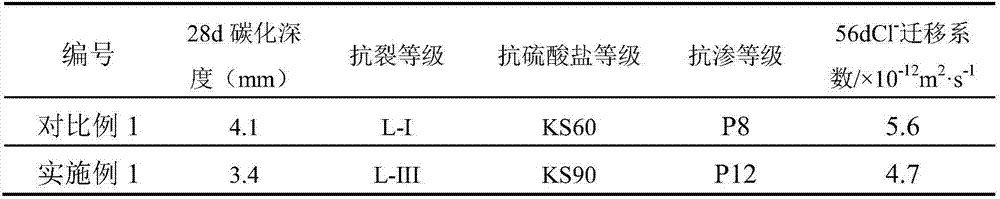

Embodiment 1

[0051] The preparation method of internal maintenance material described in embodiment 1 and embodiment 2 comprises the following steps:

[0052] 1) Use magnesite, bauxite, limestone and gypsum powder as raw materials, mix and grind them evenly, calcinate at 1000-1200°C for 10-15min, and then grind to 60μm square hole sieve residue ≤ 5% after natural cooling, Prepare expansion component A; wherein the mass percentage of each raw material is: magnesite 20-25%, bauxite 15-20%, limestone 30-40%, gypsum powder 15-35%, and control Al 2 o 3 / SO 3The molar ratio is 0.4-0.5, the CaO / MgO molar ratio is 0.1-0.3, and the alkalinity coefficient Cm is 3.1-3.5; the obtained expansion component A contains MgO, C 4 The mass percentages of AF and AFt are 30-40%, 10-15% and 45-60% respectively;

[0053] 2) Put the tapioca starch in water and stir evenly to form a starch slurry, adjust the pH value to 6.0-6.5, and then put it in a water bath at 55-80°C under the stirring condition of 200-250r...

Embodiment 2

[0080] A sea sand corrosion-resistant marine concrete, which is made of cement, fly ash microbeads, silica fume, mineral powder, gravel, sea sand, internal maintenance materials, pore structure adjustment and erosive ion transport inhibitors, hyperdispersion shrinkage reduction Type admixture and water are prepared as raw materials, and its preparation method includes the following steps: take the raw materials according to the ratio described in Table 2-1, mix cement, fly ash microbeads, mineral powder, internal maintenance materials, crushed stone and Pour sea sand into a concrete mixer and dry mix for 3 minutes to mix evenly, then add water, pore structure adjustment, aggressive ion transport inhibitor, and ultra-dispersed shrinkage-reducing admixture, and continue to stir for 10 to 15 minutes to mix evenly to obtain the sea sand Corrosion-resistant marine concrete (C40).

[0081] The working performance and mechanical performance test results of the sea sand corrosion-resi...

Embodiment 3

[0089] A sea sand corrosion-resistant marine concrete, which is made of cement, fly ash microbeads, silica fume, mineral powder, gravel, sea sand, internal maintenance materials, pore structure adjustment and erosive ion transport inhibitors, hyperdispersion shrinkage reduction Type admixture and water are prepared as raw materials, and its preparation method includes the following steps: weigh the raw materials according to the ratio described in Table 3-1, mix cement, fly ash microbeads, mineral powder, internal maintenance materials, crushed stones and Pour sea sand into a concrete mixer and dry mix for 3 minutes to mix evenly, then add water, pore structure adjustment, aggressive ion transport inhibitor, and ultra-dispersed shrinkage-reducing admixture, and continue to stir for 10 to 15 minutes to mix evenly to obtain the sea sand Corrosion-resistant marine concrete (C50). The working performance and mechanical performance test results of the C50 sea sand corrosion-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com