Ecological dustproof type seawater sea-sand anti-corrosion marine concrete and preparation method thereof

A concrete and seawater technology, applied in the field of building materials, can solve the problems of the service life not reaching the designed service life, the reduction of concrete durability, the increase of the corrosion rate of steel bars, etc., to inhibit the erosion of ions, reduce the water-binder ratio, reduce The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

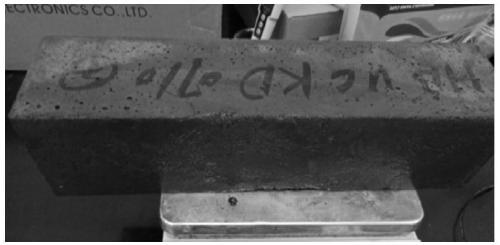

Embodiment 1

[0039] An ecological anti-corrosion type seawater sea sand corrosion-resistant marine concrete material is prepared by the following method:

[0040] Step 1, take the following raw materials by weight for later use: 50 parts of cement, 15 parts of silica fume, 20 parts of fly ash microbeads, 15 parts of blast furnace slag powder, 1 part of corrosive ion inhibitor nicotinic acid, 110 parts of sea sand, 10 parts of steel fiber, 2 parts of water reducer, 12 parts of sea water.

[0041] Step 2: Mix cement, silica fume, fly ash microbeads, blast furnace slag powder, nicotinic acid, and steel fiber in proportion and stir evenly with a mixer, add sea sand and continue stirring evenly, then add seawater and water reducer and mechanically stir for 8 ~10 minutes until the mixture is evenly stirred to make an ecological rust-resistant seawater sea sand corrosion-resistant marine concrete slurry.

[0042] Step 3, after pouring for 24 hours, remove the formwork and then place it at 80°C a...

Embodiment 2

[0048] An ecological anti-corrosion type seawater sea sand corrosion-resistant marine concrete material is prepared by the following method:

[0049] Step 1, take the following raw materials by weight for later use: 40 parts of cement, 10 parts of silica fume, 25 parts of fly ash microbeads, 10 parts of blast furnace slag powder, 5 parts of corrosive ion inhibitor nicotinic acid, 130 parts of sea sand, 15 parts of steel fiber, 5 parts of superplasticizer, 15 parts of sea water.

[0050] Step 2: Mix cement, silica fume, fly ash microbeads, blast furnace slag powder, nicotinic acid, and steel fiber in proportion and stir evenly with a mixer, add sea sand and continue stirring evenly, then add seawater and water reducer and mechanically stir for 8 ~10 minutes until the mixture is evenly stirred to make an ecological rust-resistant seawater sea sand corrosion-resistant marine concrete slurry.

[0051] Step 3, after pouring for 24 hours, remove the formwork and then place it at 80...

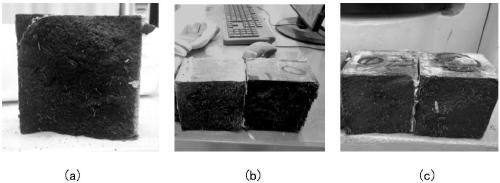

Embodiment 3

[0056] An ecological anti-corrosion type seawater sea sand corrosion-resistant marine concrete material is prepared by the following method:

[0057] Step 1, take the following raw materials by weight for later use: 46 parts of cement, 13 parts of silica fume, 22 parts of fly ash microbeads, 14 parts of blast furnace slag powder, 3 parts of corrosive ion inhibitor nicotinic acid, 117 parts of sea sand, 12 parts of steel fiber, 3 parts of water reducing agent, 10 parts of sea water.

[0058] Step 2: Mix cement, silica fume, fly ash microbeads, blast furnace slag powder, nicotinic acid, and steel fiber in proportion and stir evenly with a mixer, add sea sand and continue stirring evenly, then add seawater and water reducer and mechanically stir for 8 ~10 minutes until the mixture is evenly stirred to make an ecological rust-resistant seawater sea sand corrosion-resistant marine concrete slurry.

[0059] Step 3, after pouring for 24 hours, remove the formwork and then place it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com