A kind of maltose derived carbon/lithium sulfide composite electrode material and its preparation method and application

A composite electrode, maltose technology, applied in the direction of positive electrode, battery electrode, lithium battery, etc., can solve the problems of unsolved polysulfide shuttle effect, limited research on lithium sulfide insulation characteristics, and reduced battery safety performance, etc., to reduce irreversible capacity. , Improve the rate performance and cycle performance, and promote the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Wash the purchased glutinous rice, pour it into a pot and cook it, stir it with the chopped malt, and let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature into a paste, which becomes amber-shaped sugar lumps after cooling. Lithium sulfate solution was prepared with lithium sulfate and deionized water. The mass ratio of lithium sulfate, deionized water, and maltose was 1:2:4. The solution was poured into maltose and stirred for 30 minutes, and then freeze-dried in a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated at 600 °C for 4 hours in argon, and then transferred to a tube furnace for sintering at 850 °C for 3 hours. The heating rate was 5 °C / min. After cooling, maltose-derived carbon / lithium sulfide was obtained. composite material.

Embodiment 2

[0036] Wash the purchased glutinous rice, pour it into a pot and cook it, stir it with the chopped malt, and let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature into a paste, which becomes amber-shaped sugar lumps after cooling. Lithium sulfate solution was prepared with lithium sulfate and deionized water. The mass ratio of lithium sulfate, deionized water, and maltose was 1:2:4. The solution was poured into maltose and stirred for 30 minutes, and then freeze-dried in a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated at 600 °C for 4 hours in argon, and then transferred to a tube furnace for sintering at 850 °C for 5 hours. The heating rate was 5 °C / min. After cooling, maltose-derived carbon / lithium sulfide was obtained. composite material.

Embodiment 3

[0038] Wash the purchased glutinous rice, pour it into a pot and cook it, stir it with the chopped malt, and let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature into a paste, which becomes amber-shaped sugar lumps after cooling. Lithium sulfate solution was prepared with lithium sulfate and deionized water. The mass ratio of lithium sulfate, deionized water, and maltose was 1:2:4. The solution was poured into maltose and stirred for 30 minutes, and then freeze-dried in a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated at 600 °C for 4 hours in argon, and then transferred to a tube furnace for sintering at 850 °C for 4 hours. The heating rate was 5 °C / min. After cooling, maltose-derived carbon / lithium sulfide was obtained. composite material.

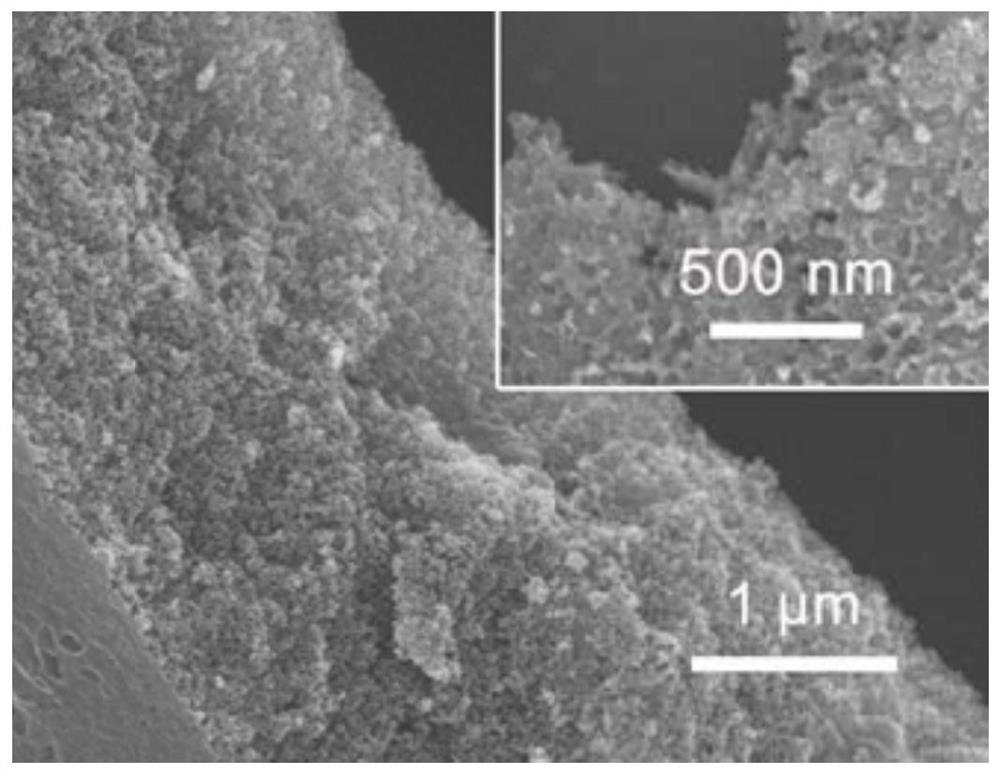

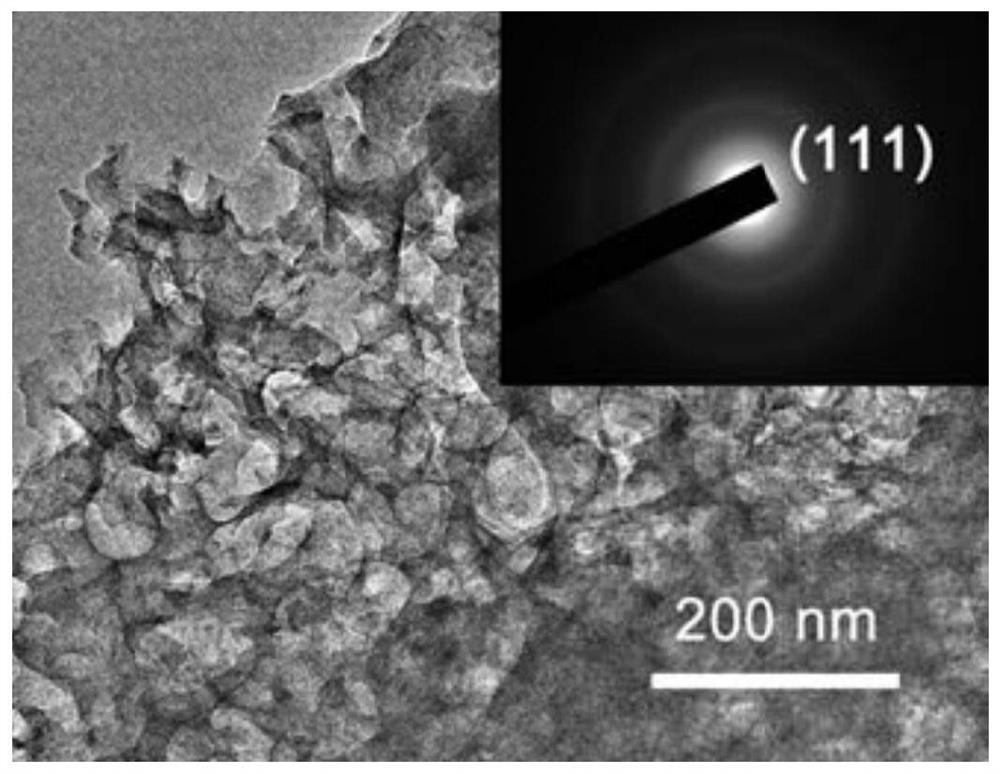

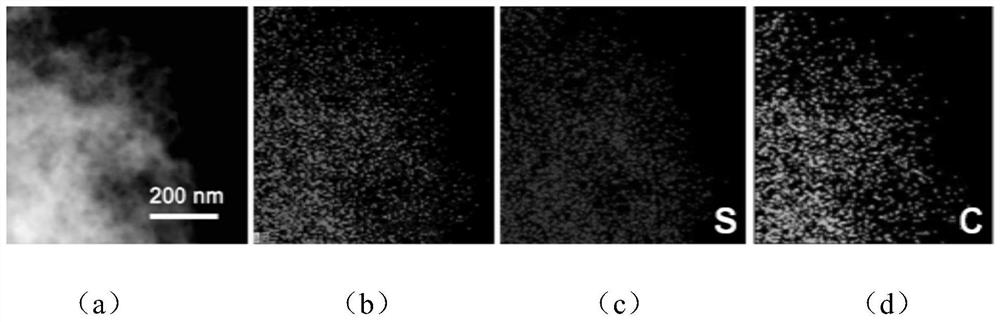

[0039] figure 1 It is a scanning electron microscope image of the maltose-derived carbon / lithium sulfide composite material prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com