Deicing salt-resisting cement-based channel repairing agent

A technology of salt cement and repairing agent, which is used in cement-based repairing agent for drainage ditch and the field of road side ditch which is resistant to deicing salt corrosion, can solve the problem of not having impermeability and deicing salt corrosion resistance, and not having salt resistance. Corrosion and impermeability, lack of impermeability and bonding ability, etc., to achieve the effect of improving bond strength and impermeability, improving workability and fluidity, and reducing segregation and bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

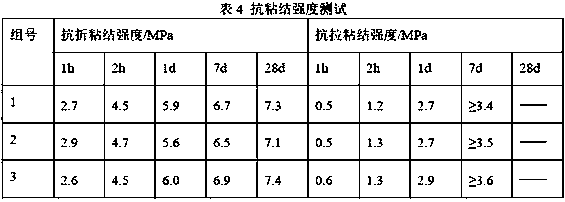

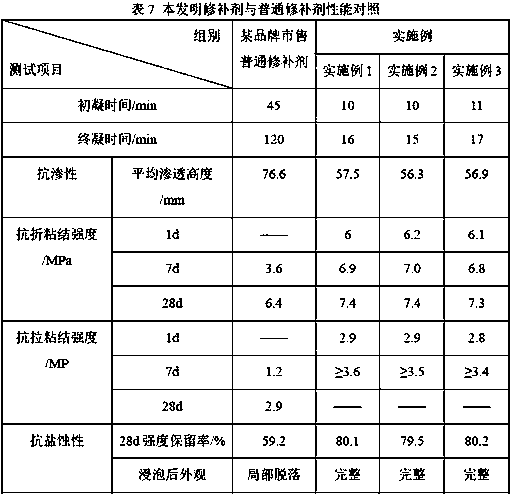

Examples

Embodiment 1

[0021] An anti-deicing salt cement-based ditch repair agent, its material ratio and preparation method are as follows: 10% potassium dihydrogen phosphate, 16% magnesium oxide, 3% borax, 4.5% calcium carbonate are weighed sequentially according to the required ratio of raw materials , 18.4% fly ash, 3% silica fume, 0.1% polyacrylamide, 0.3% triterpene saponin air-entraining agent, 0.2% polycarboxylate superplasticizer, 24% fine aggregate, 15% coarse aggregate, The remaining water; put the weighed potassium dihydrogen phosphate, magnesium oxide, borax, calcium carbonate, fine aggregate, coarse aggregate, fly ash and microsilica fume in a mixer for 5 minutes; add air-entraining agent and water reducer 1. Continue to stir the polyacrylamide for 2 minutes to make it evenly mixed, and finally add water and stir for 2 minutes until a paste-like slurry with good fluidity is formed.

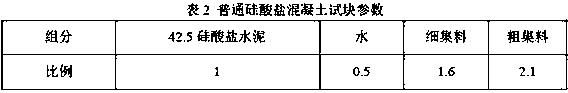

[0022] 1. Performance test method.

[0023] (1) Coagulation time.

[0024] The experimental equipmen...

Embodiment 2

[0045] An anti-deicing salt cement-based ditch repair agent, its material ratio and preparation method are as follows: according to the required ratio of raw materials, take 12% potassium dihydrogen phosphate, 18% magnesium oxide, 5% borax, and 3% calcium carbonate in sequence , 16.9% fly ash, 1.6% silica fume, 0.2% polyacrylamide, 0.2% triterpene saponin air-entraining agent, 0.1% polycarboxylate superplasticizer, 23% fine aggregate, 13% coarse aggregate, The remaining water; put the weighed potassium dihydrogen phosphate, magnesium oxide, borax, calcium carbonate, fine aggregate, coarse aggregate, fly ash and microsilica fume in a mixer for 5 minutes; add air-entraining agent and water reducer 1. Continue to stir the polyacrylamide for 2 minutes to make it evenly mixed, and finally add water and stir for 2 minutes until a paste-like slurry with good fluidity is formed.

Embodiment 3

[0047] An anti-deicing salt cement-based ditch repair agent, its material ratio and preparation method are as follows: according to the required ratio of raw materials, 11% potassium dihydrogen phosphate, 17% magnesium oxide, 5% borax, and 4% calcium carbonate are sequentially weighed , 16% fly ash, 1.8% silica fume, 0.15% polyacrylamide, 0.2% triterpene saponin air-entraining agent, 0.15% polycarboxylate superplasticizer, 24% fine aggregate, 14% coarse aggregate, The remaining water; put the weighed potassium dihydrogen phosphate, magnesium oxide, borax, calcium carbonate, fine aggregate, coarse aggregate, fly ash and microsilica fume in a mixer for 5 minutes; add air-entraining agent and water reducer 1. Continue to stir the polyacrylamide for 2 minutes to make it evenly mixed, and finally add water and stir for 2 minutes until a paste-like slurry with good fluidity is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com