Slurry-rich concrete additive and preparation method thereof

A technology for concrete and additives, which is applied to the preparation of the slurry-rich concrete additive, an additive that can increase the volume of concrete slurry, and the field of slurry-rich concrete additives, which can solve the problem of not giving a guiding scheme and the like, and achieve a rich slurry. , good fluidity, small effect with time change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

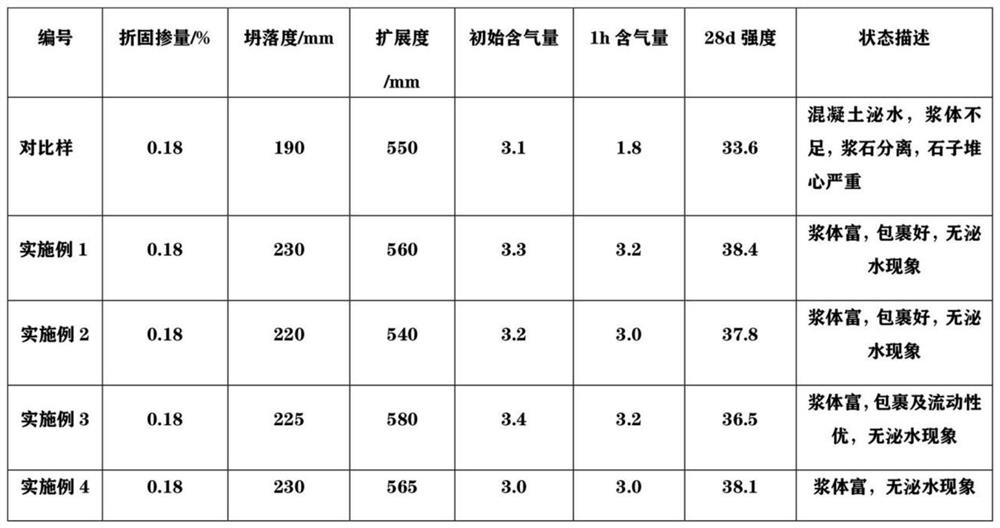

[0021] Example 1: The slurry-rich concrete additive described in the present invention is compounded by rapidly absorbing and dispersing water-reducing agent, air-entraining water-reducing agent, water-retaining agent, air-entraining agent, and deionized water. The mass ratio is: fast adsorption and dispersion water reducer: air-entraining type water reducer: water retention agent: air-entraining agent = 70:200:10:0.8, the balance is deionized water; the sum of the masses of each component is 1000g.

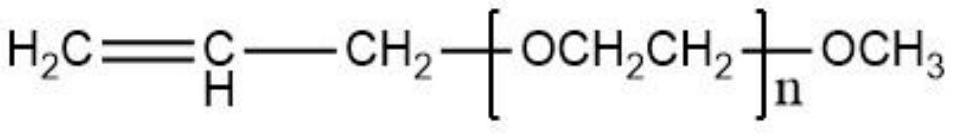

[0022] The preparation method of fast adsorption and dispersion water reducing agent: add 72 parts of allyl polyethylene glycol monomethyl ether with a molecular weight of 800 in the reaction kettle, add 48 parts of deionized water, start stirring, heat up, and prepare material A at the same time Liquid and B material liquid, A material liquid is made by mixing together 38.88 parts of acrylic acid, 18.54 parts of sodium p-styrene sulfonate, 50 parts of deionized water, B material...

Embodiment 2

[0025] Example 2: The slurry-rich concrete additive of the present invention is compounded by rapidly absorbing and dispersing water reducing agent, air-entraining water reducing agent, water-retaining agent, air-entraining agent, and deionized water. The mass ratio is: fast adsorption and dispersion water reducer: air-entraining type water reducer: water retention agent: air-entraining agent = 80:180:15:1, the balance is deionized water; the sum of the masses of each component is 1000g.

[0026] The preparation method of fast adsorption and dispersion water reducer: add 90 parts of allyl polyethylene glycol monomethyl ether with a molecular weight of 1200 into the reaction kettle, add 60 parts of deionized water, start stirring, heat up, and prepare material A at the same time Liquid and B material liquid, A material liquid is made by mixing together 43.2 parts of acrylic acid, 7.73 parts of sodium p-styrene sulfonate, 40 parts of deionized water, B material liquid is made of...

Embodiment 3

[0029] Example 3: The slurry-rich concrete additive of the present invention is compounded by rapidly absorbing and dispersing water reducer, air-entraining water reducer, water retaining agent, air-entraining agent, and deionized water. The mass ratio is: fast adsorption and dispersion water reducer: air-entraining type water reducer: water retention agent: air-entraining agent = 60:220:20:0.5, the balance is deionized water; the sum of the masses of each component is 1000g.

[0030] The preparation method of fast adsorption and dispersion water reducing agent: add 80 parts of allyl polyethylene glycol monomethyl ether with a molecular weight of 800 in the reaction kettle, add 55 parts of deionized water, start stirring, heat up, and prepare material A at the same time Liquid and B material liquid, A material liquid is made by mixing together 61.2 parts of acrylic acid, 20.60 parts of sodium p-styrene sulfonate, 60 parts of deionized water, B material liquid is made of mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com