Hydrolyzation resistant double-tail trisiloxane surfactant

A technology of surfactant and trisiloxane, which is applied in the field of trisiloxane surfactant and two-tailed trisiloxane surfactant, can solve the problems of being difficult to obtain, difficult to industrialize and develop, and achieves the promotion of spreading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

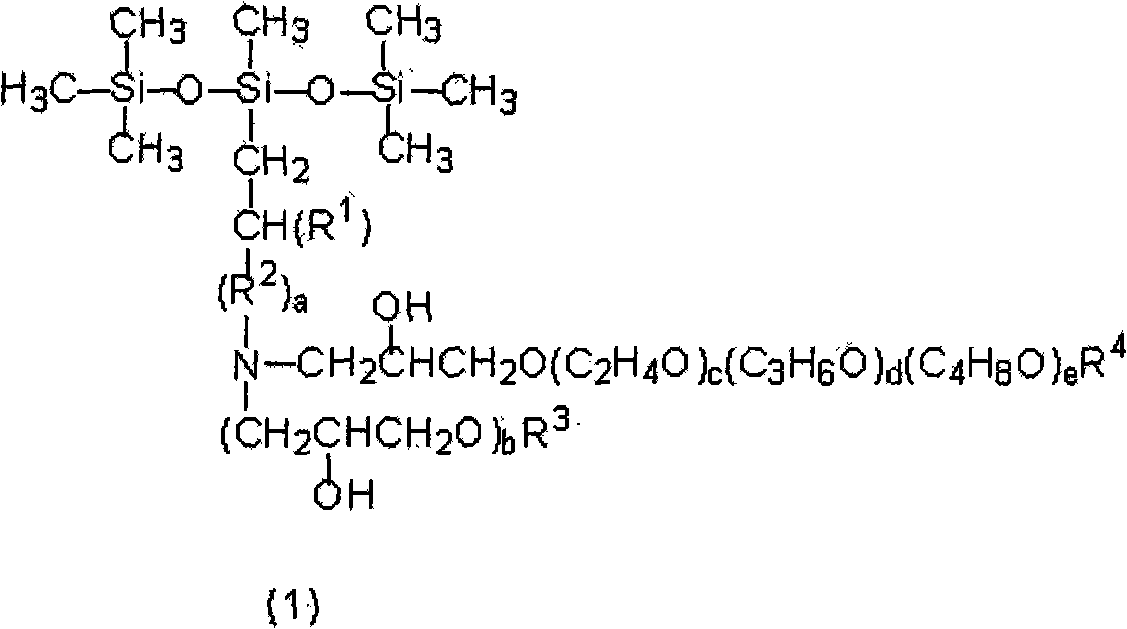

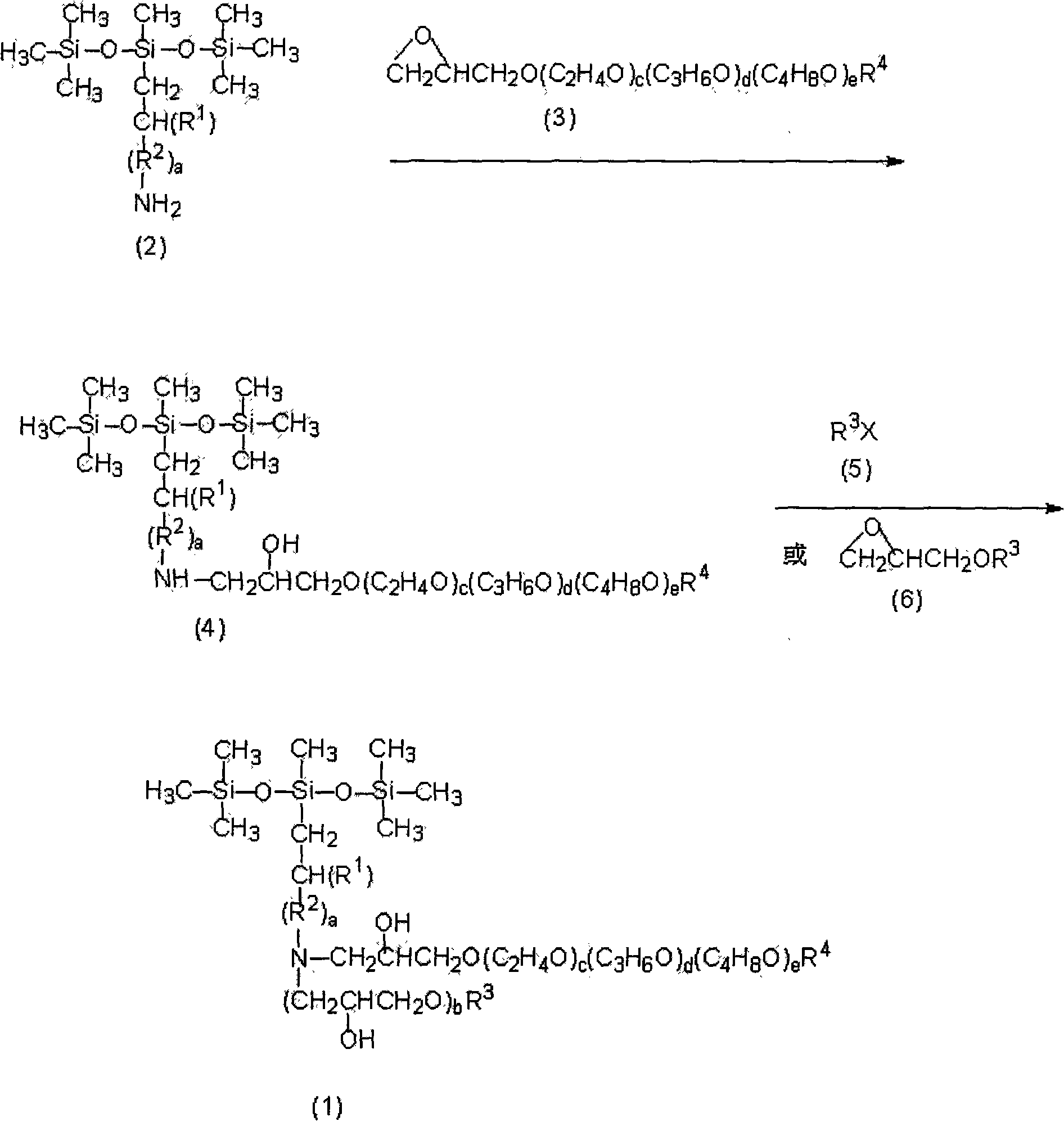

Method used

Image

Examples

Embodiment 1

[0019] Add 1.06×10 to the three-neck flask -2 Moles of 3-aminopropyl trisiloxane [compound shown in formula (2), wherein R 1 = H, R 2 =CH 2 , a=1], 0.72×10 -2 Mole methyl polyoxyethylene glycidyl ether [compound shown in formula (3), wherein R 4 =CH 3 , c=8.4, d=e=0] and 44 milliliters of toluene, feed nitrogen to replace the air in the reactor, under nitrogen protection, reflux for 3 hours, distill off the solvent and excess aminoalkyltrisiloxane to obtain the formula (4) shown single tail surfactant (wherein R 1 = H, R 2 =CH 2 , R 4 =CH 3 , a=1, c=1, d=e=0; MS1 for short).

[0020] Add 0.7×10 to the three-neck flask -2 mol of the single-tailed surfactant (MS1) prepared earlier, 0.70×10 -2 mole n-octane bromide 1.40×10 -2 Mole of sodium carbonate and 40 milliliters of toluene, feed nitrogen to replace the air in the reactor, under nitrogen protection, react at 80-110°C for 10 hours, cool down, filter to remove the filter residue, and the filtrate is distilled to ...

Embodiment 2

[0022] Add 1.0×10 to the three-neck flask -2 Moles of 3-aminopropyl trisiloxane [compound shown in formula (2), wherein R 1 = H, R 2 =CH 2 , a=1], 0.70×10 -2 Mole methyl polyoxyethylene glycidyl ether [compound shown in formula (3), wherein R 4 =CH 3 , c=12.9, d=e=0] and 42 milliliters of toluene, feed nitrogen to replace the air in the reactor, under nitrogen protection, reflux for 3 hours, distill off solvent and excess 3-aminopropyl trisiloxane The single-tail surfactant (wherein R) shown in alkane formula (4) 1 = H, R 2 =CH 2 , R 4 =CH 3 , a=1, c=12.9, d=e=0; MS2 for short).

[0023] Add 0.60×10 to the three-neck flask -2 The single tail surfactant (MS2) prepared in front of mole, 0.60×10 -2 mole n-octane bromide 1.20×10 -2 Mole of sodium carbonate and 40 milliliters of toluene, feed nitrogen to replace the air in the reactor, under nitrogen protection, react at 80-110°C for 10 hours, cool down, filter to remove the filter residue, and the filtrate is distille...

Embodiment 3

[0025] In the there-necked flask, add the single tail surfactant (MS1) 0.70×10 prepared by the embodiment -2 mole, n-octyl glycidyl ether 0.70×10 -2mol and 40 milliliters of toluene, feed nitrogen to replace the air in the reactor, under the protection of nitrogen, react at 80~110°C for 10 hours, distill off the solvent to obtain the double tail surfactant shown in formula (1) (wherein R 1 = H, R 2 =CH 2 , R 3 =n-C 8 h 17 , R 4 =CH 3 , a=1, c=8.4, b=1, d=e=0; DS3 for short).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com