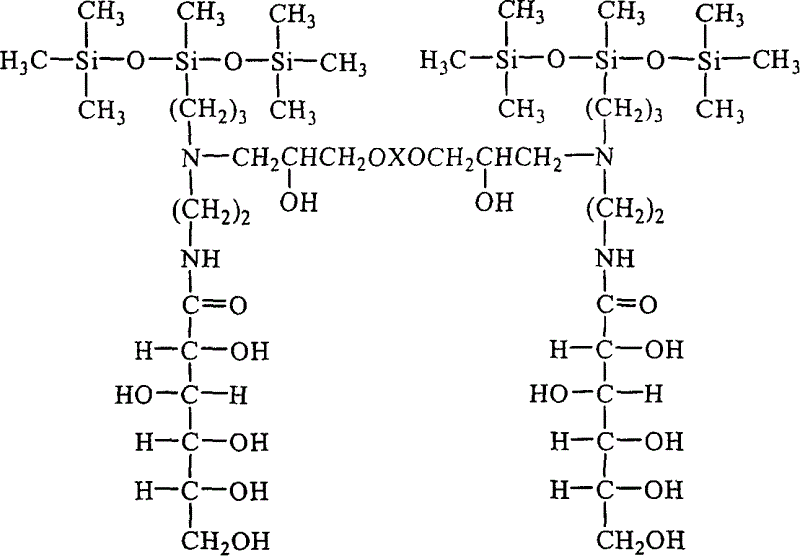

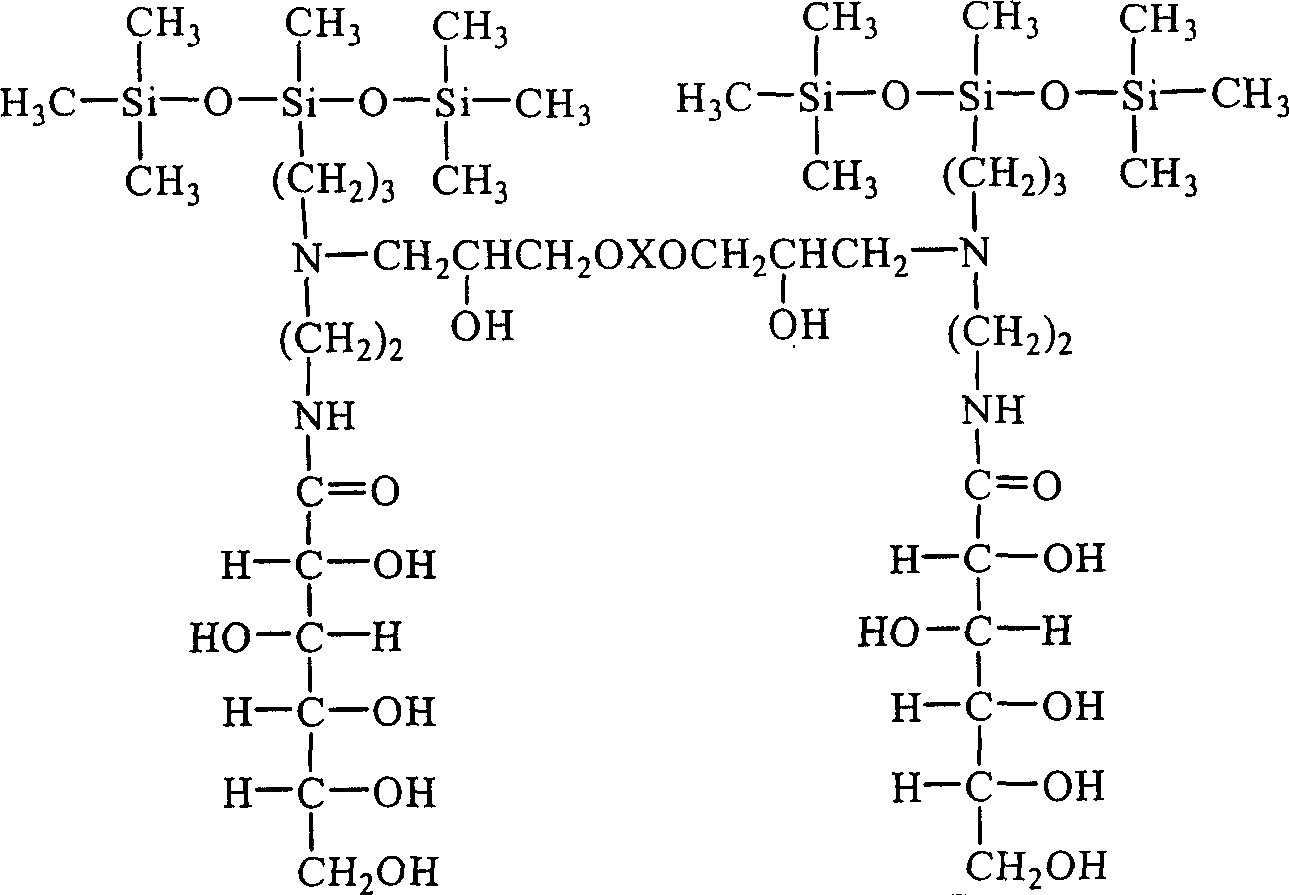

Dipolytrisiloxane surfactant containing glucose amide and its preparation method

A technology of dimer trisiloxane and surfactant, which is applied in the field of dimer trisiloxane surfactant and its preparation, and achieves the effect of good spreadability and promotion of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 1.62kg of hexamethyldisiloxane, 2.06kg of aminoethylaminopropyldimethoxymethylsilane, and 1.82g of tetramethylammonium hydroxide into the reaction kettle, heat to dissolve, and control the temperature at 100°C. After 4 hours, the temperature was raised to 130° C. to deactivate the catalyst. Evaporate aminoethylaminopropyl trisiloxane under reduced pressure, add equimolar gluconolactone, use methanol as solvent, heat to reflux, and react for 8 hours. Then add 0.5 moles of ethylene glycol diglycidyl ether, and continue to react for 12 hours. The solvent methanol is evaporated to obtain the product. The minimum surface tension of its aqueous solution measured by K12 surface tension meter is 20.5mN / m, and the critical micelle concentration is 1.9×10 -5 mol / L, the minimum contact angle on the quartz surface is 0°.

Embodiment 2

[0023] Add 8.10kg of hexamethyldisiloxane, 2.34kg of aminoethylaminopropyldiethoxymethylsilane, and 168g of potassium hydroxide into the reaction kettle, heat to dissolve, and control the temperature at 120°C. After 5 hours of reaction, Add acetic acid to neutralize the catalyst to deactivate it, and then evaporate unreacted hexamethyldisiloxane. Evaporate aminoethylaminopropyl trisiloxane under reduced pressure, add equimolar gluconolactone, use methanol as solvent, heat to reflux, and react for 10 hours. Then add 0.5 moles of diethylene glycol diglycidyl ether, and continue to react for 12 hours. The solvent methanol is evaporated to obtain the product. The lowest surface tension of its aqueous solution measured by K12 surface tension meter is 20.6mN / m, and the critical micelle concentration is 2.9×10 -5 mol / L, the minimum contact angle on the quartz surface is 0°.

Embodiment 3

[0025] Add 16.20kg of hexamethyldisiloxane, 2.06kg of aminoethylaminopropyldimethoxymethylsilane, and 151.8g of tetrabutylphosphonium hydroxide into the reaction kettle, heat to dissolve, control the temperature at 80°C, and react for 4 hours Afterwards, the temperature was raised to 110° C. to deactivate the catalyst, and at the same time, unreacted hexamethyldisiloxane was distilled off. Evaporate aminoethylaminopropyl trisiloxane under reduced pressure, add equimolar gluconolactone, use methanol as solvent, heat to reflux, and react for 8 hours. Then add 0.5 moles of triethylene glycol diglycidyl ether, and continue to react for 12 hours. The solvent methanol is evaporated to obtain the product. The minimum surface tension of its aqueous solution measured by K12 surface tension meter is 20.7mN / m, and the critical micelle concentration is 3.3×10 -5 mol / L, the minimum contact angle on the quartz surface is 5°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com