Self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper

A composite damping and viscoelastic technology, applied in building components, shockproof, building types, etc., can solve the problems of friction damper reaction delay, viscoelastic material and steel plate tearing, etc., to prolong the natural vibration period, protect the safety of the structure, The effect of increasing the structural damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

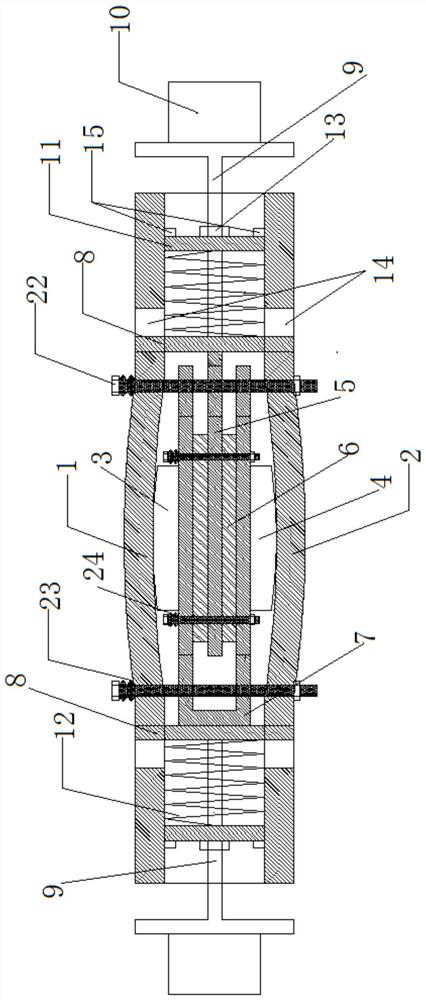

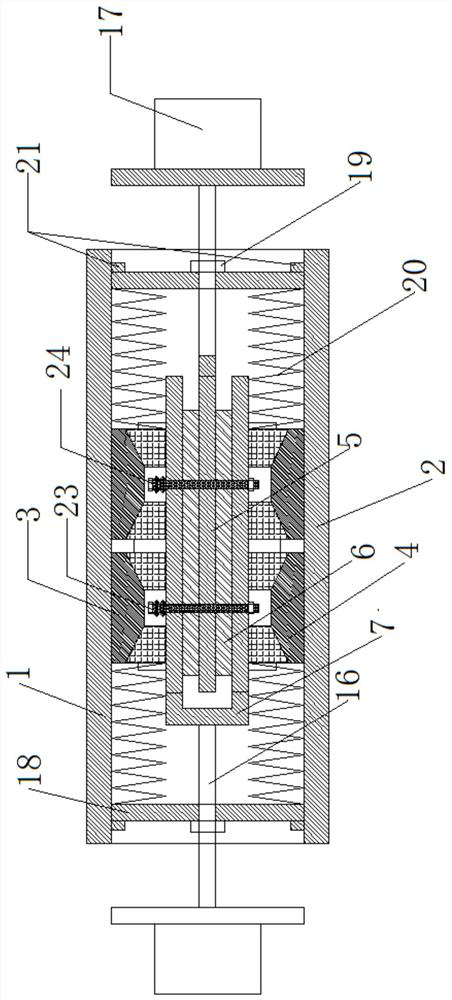

[0044] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0045] In a specific embodiment, such as figure 1 , 2 As shown, the self-reset variable damping variable stiffness viscoelasticity and friction compound damper includes: a relatively fixed first friction substrate 1 and a second friction substrate 2; The viscoelastic damper between the two friction substrates 2 is provided with a first friction plate 3 and a second friction plate 4 on the corresponding two sides of the fixed end respectively, and is correspondingly crimped on the first friction substrate 1 and the on the second friction substrate 2. The self-resetting variable damping variable stiffness viscoelastic and frictional composite damper provided by this technical solution, the internal viscoelastic damper unit can dissipate energy and shock for hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com