High-performance semi-metallic brake pad

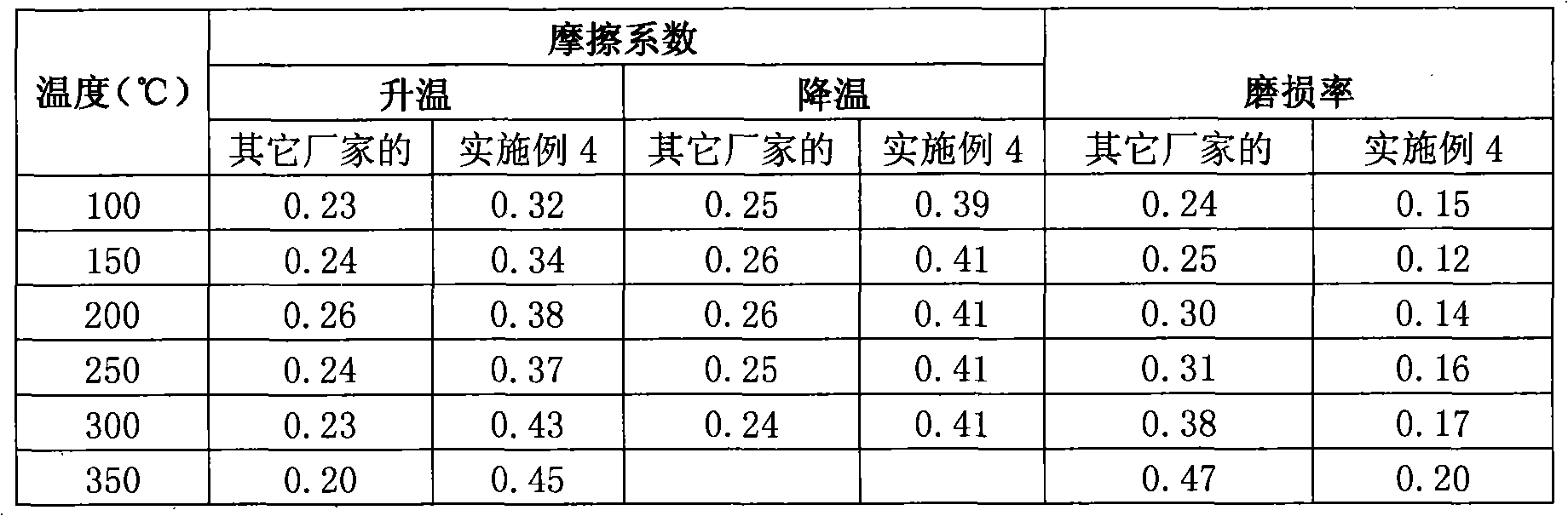

A technology of semi-metal and brake pads, applied in the field of high-performance semi-metal brake pads, can solve the problems of large damage to brake drums or brake discs, easy corrosion of semi-metal brake pads, high thermal conductivity, etc., and achieve high-temperature thermal fading resistance Good, stable friction coefficient, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: by weight 4% of nitrile rubber powder, tire powder (60-80 order) 3%, flake graphite 5%, foam iron powder 6%, boron phenolic resin 13%, pulverized shaped steel fiber 8%, oxidation Aluminum fiber 4%, copper fiber 11%, cashew nut oil friction powder 5%, graphite particles 2%, calcined petroleum coke 3%, barite (500-600 mesh) 13%, chromite powder (300-350 mesh ) 3%, magnetite powder 2%, diatomite (500-600 mesh) 2%, spray aluminum silicate fiber 7%, flake aluminum powder 4%, molybdenum disulfide 3%, zinc stearate 0.5% , antimony sulfide 0.7%, copper sulfide 0.5%, tungsten carbide powder (250-300 mesh) 0.3% put into the high-speed disperser, stir it into powder, take it out, put it into the forming mold and press it, and then compound it with the steel back Then put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa, keep it for 15 minutes, then take out the brake pads, remove the burrs and become a finished product.

Embodiment 2

[0018] Embodiment 2: by weight 6% of NBR powder, tire powder (60-80 order) 4%, flake graphite 3%, foam iron powder 9%, boron phenolic resin 9%, pulverized shaped steel fiber 11%, oxidation Aluminum fiber 2%, copper fiber 10%, cashew nut oil friction powder 3%, graphite particles 3%, calcined petroleum coke 2%, barite (500-600 mesh) 10%, chromite powder (300-350 mesh ) 4%, magnetite powder 3%, diatomite (500-600 mesh) 3%, spray aluminum silicate fiber 9%, flake aluminum powder 3.8%, molybdenum disulfide 2.5%, zinc stearate 0.2% , 1% antimony sulfide, 1% copper sulfide, and 0.5% tungsten carbide powder (250-300 mesh) are placed in a high-speed disperser, stirred into powder, taken out, and then put into a forming mold for pressing and forming, and then compounded with a steel back Then put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa, keep it for 15 minutes, then take out the brake pads, remove the burrs and become a finished product....

Embodiment 3

[0019] Embodiment 3: by weight 5% of nitrile rubber powder, tire powder (60-80 order) 2.5%, flake graphite 4%, foam iron powder 7%, boron phenolic resin 10%, pulverized shaped steel fiber 9%, oxidation Aluminum fiber 3%, copper fiber 8%, cashew nut oil friction powder 4%, graphite particles 3%, calcined petroleum coke 2.5%, barite (500-600 mesh) 12%, chromite powder (300-350 mesh ) 4%, magnetite powder 3%, diatomite (500-600 mesh) 3.5%, spray aluminum silicate fiber 10%, flake aluminum powder 3%, molybdenum disulfide 4%, zinc stearate 0.4% , antimony sulfide 0.9%, copper sulfide 0.8%, tungsten carbide powder (250-300 mesh) 0.4% put into the high-speed disperser, stir it into powder, take it out, put it into the forming mold and press it, and then compound it with the steel back Then put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa, keep it for 15 minutes, then take out the brake pads, remove the burrs and become a finished product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com