Tube-type electric motor

A tubular motor, tubular technology, applied in electrical components, electromechanical devices, mechanical equipment, etc., to achieve the effects of simplified structure, low energy consumption, and reasonable overall structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

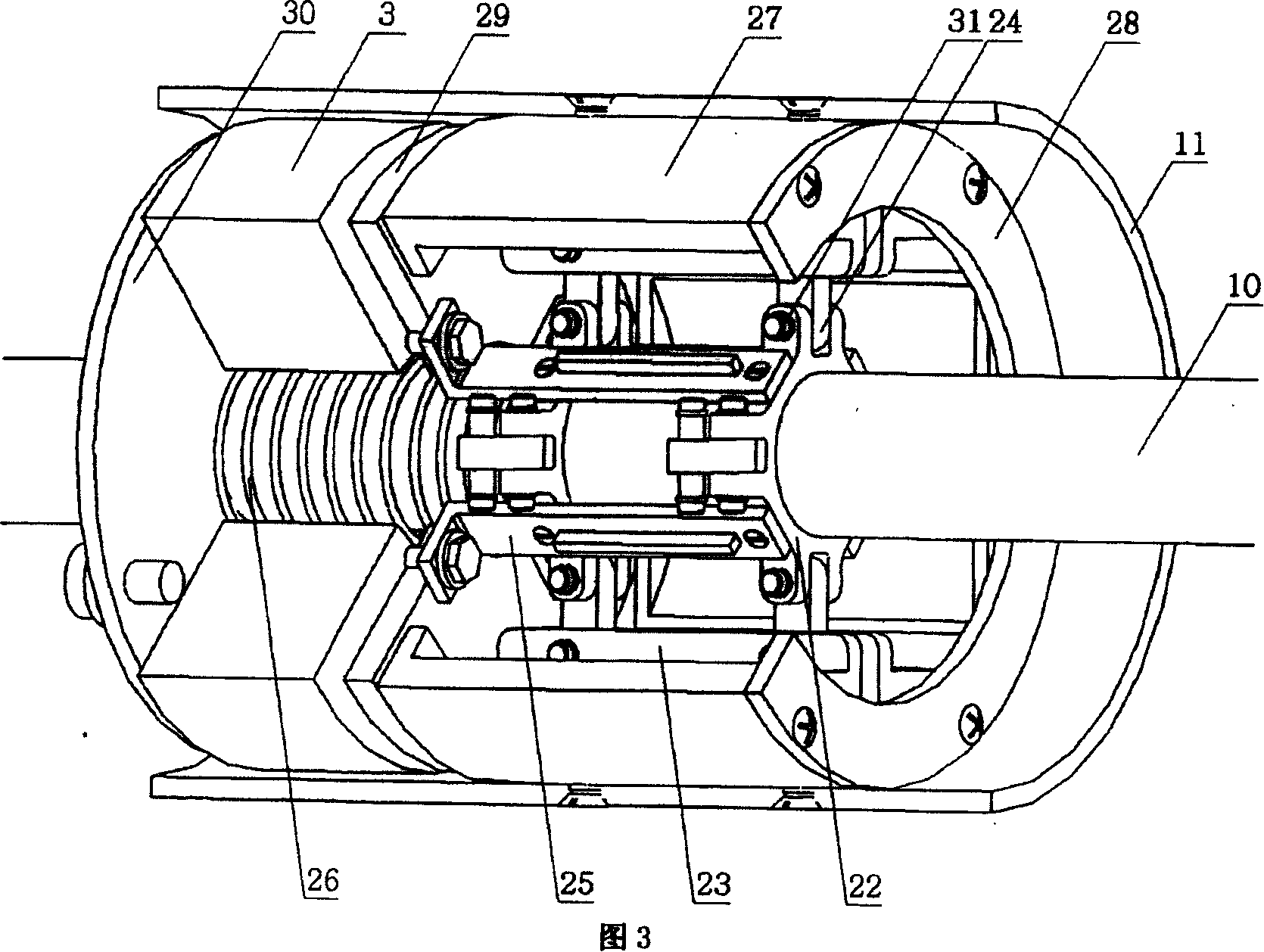

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

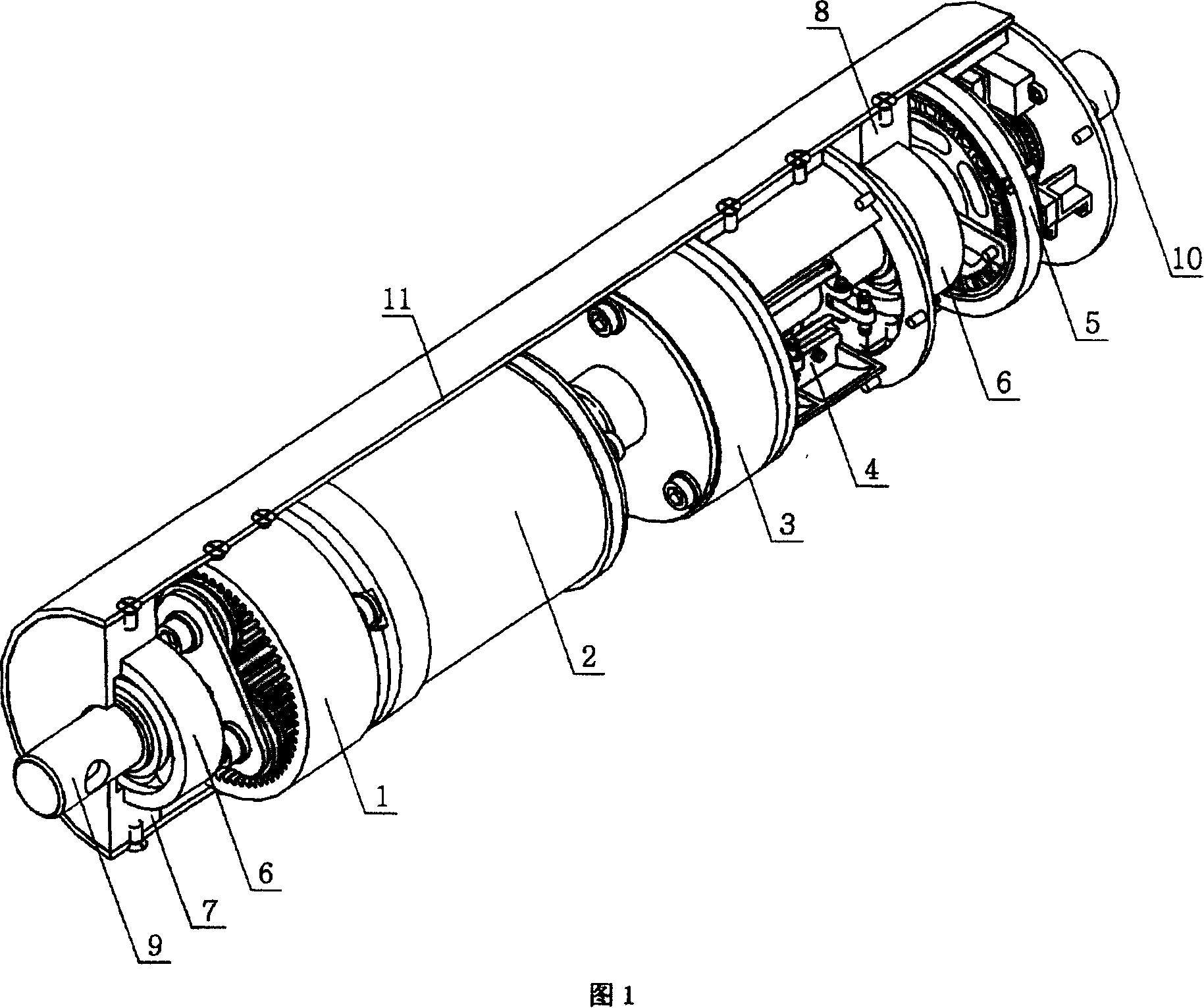

[0041] Referring to Fig. 1, a tubular motor includes a tubular casing 11 and a drive assembly supported in the tubular casing 11 through a bearing seat, a brake assembly and a stroke control assembly. The drive assembly consists of a small volume, low speed, large The low-speed motor 2 of the torque and the single-stage planetary gear transmission mechanism 1 driven by the low-speed motor 2 constitute.

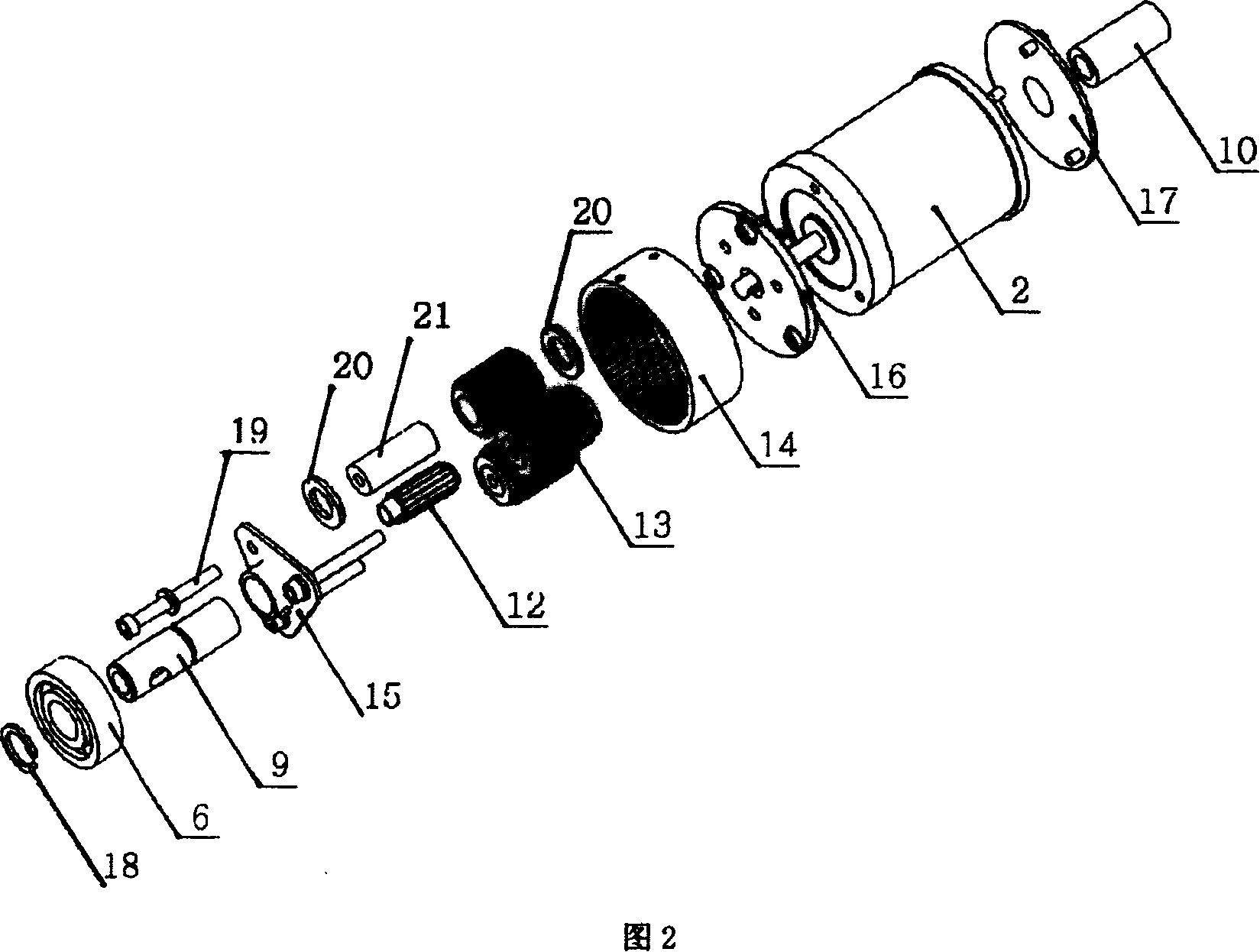

[0042] The low-speed motor 2 is a permanent magnet synchronous motor that directly obtains a low speed by the motor without a reduction gear device. Or a low-speed DC servo motor composed of a multi-stage special steel reducer and a servo DC motor.

[0043] Referring to Fig. 2, the single-stage planetary gear transmission mechanism 1 that it adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com