Patents

Literature

30results about How to "Play the role of internal plasticization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

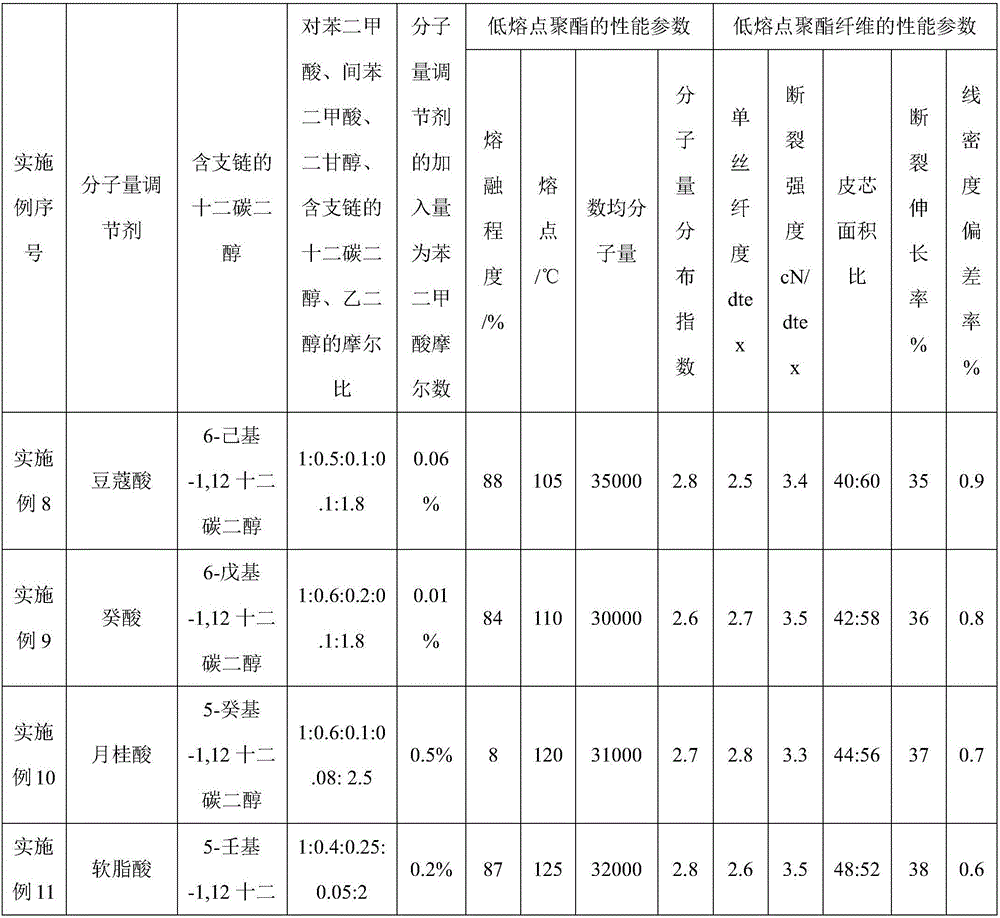

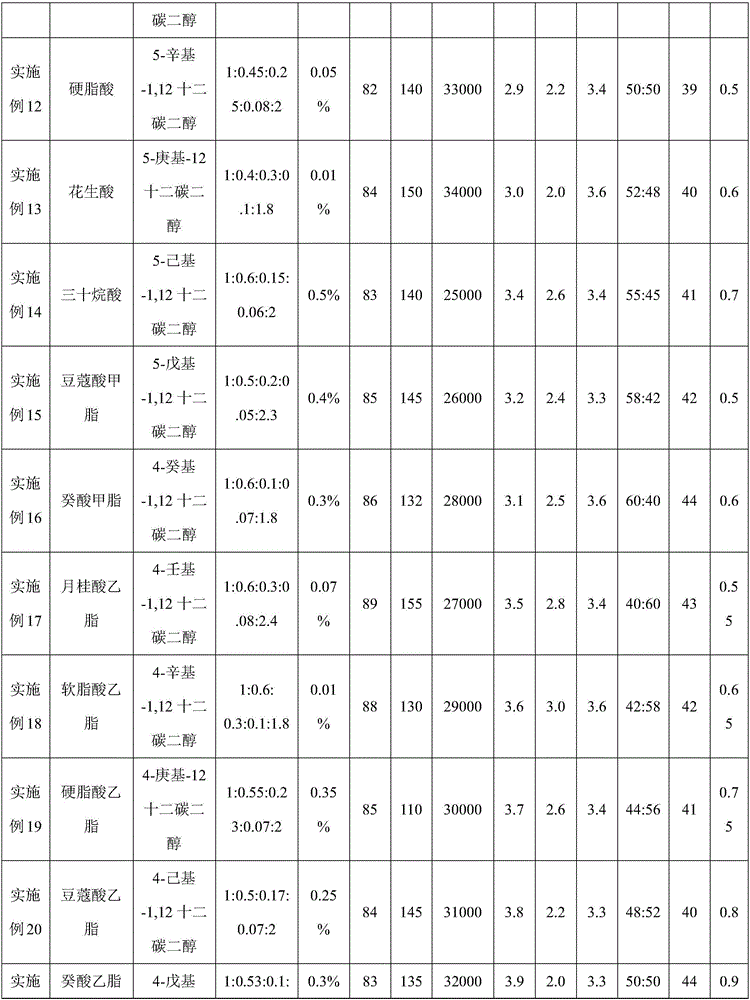

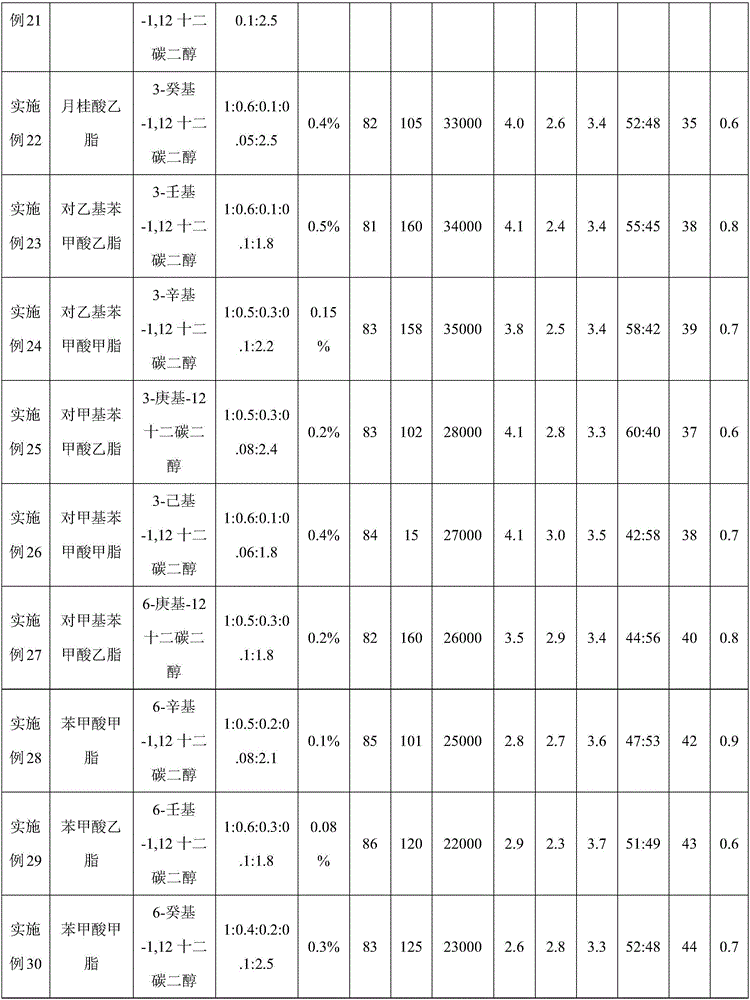

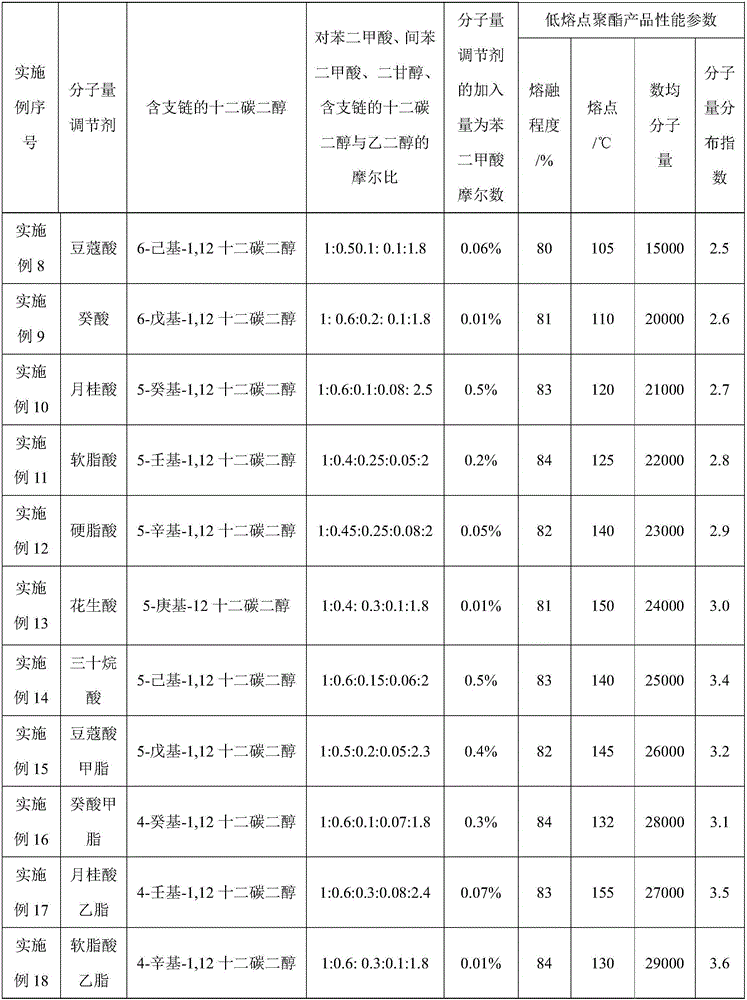

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

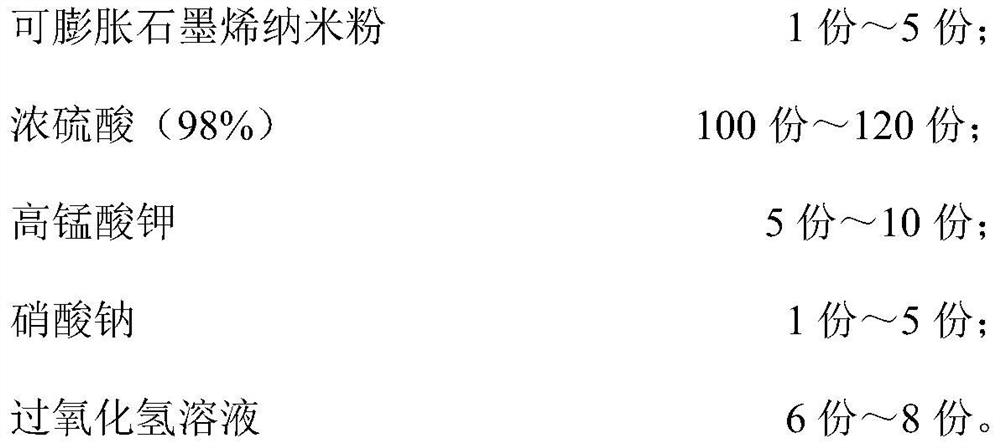

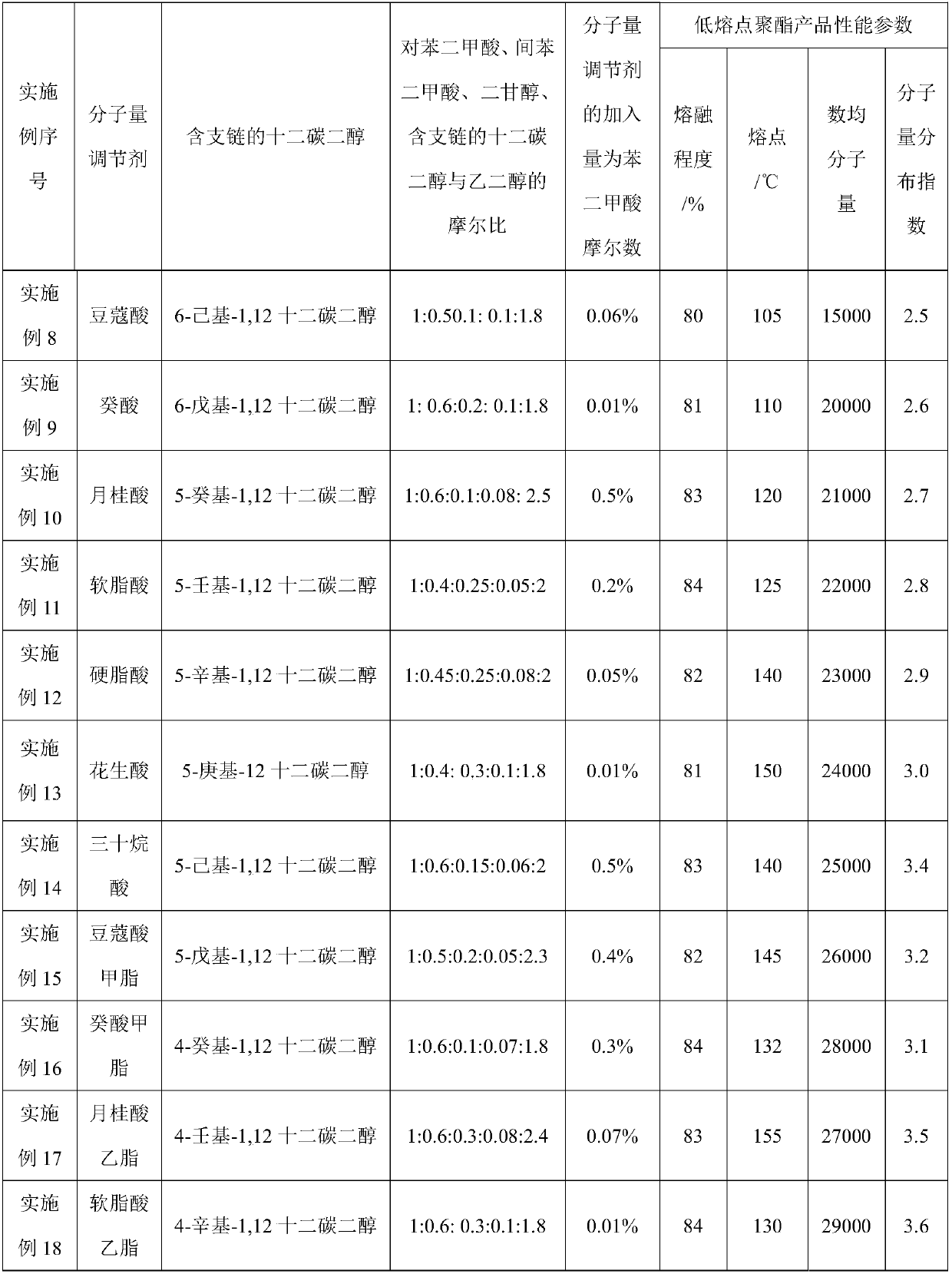

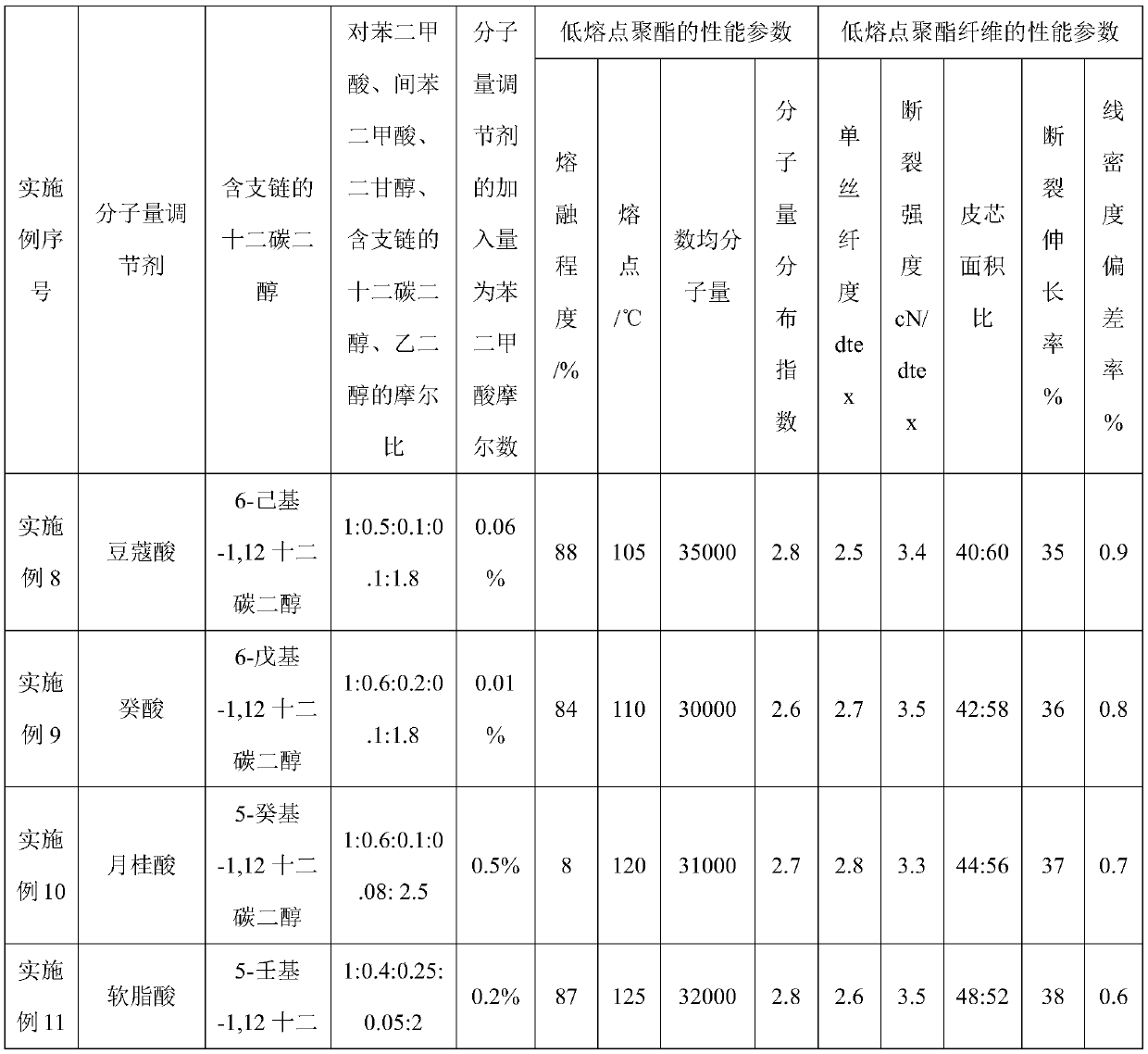

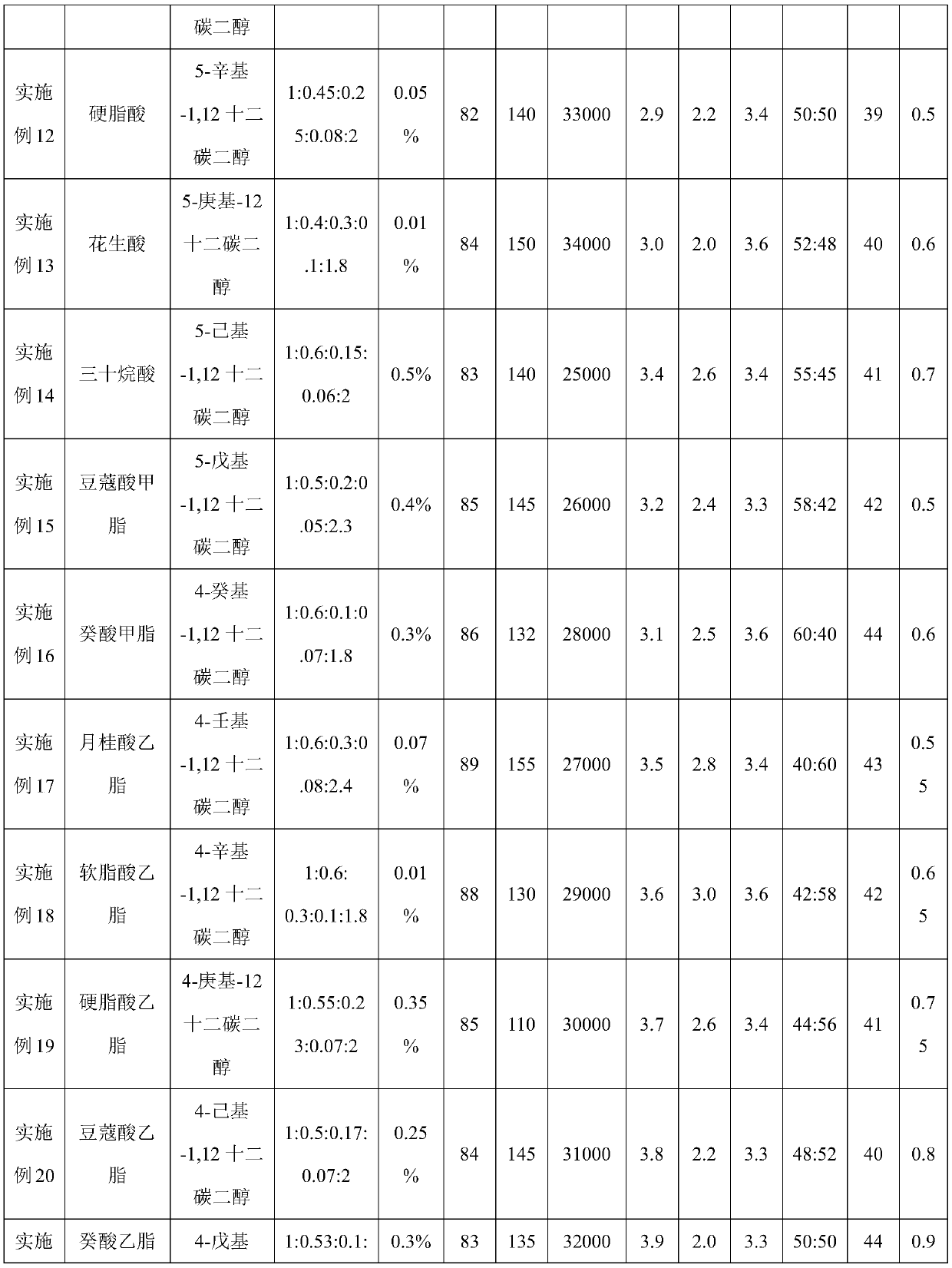

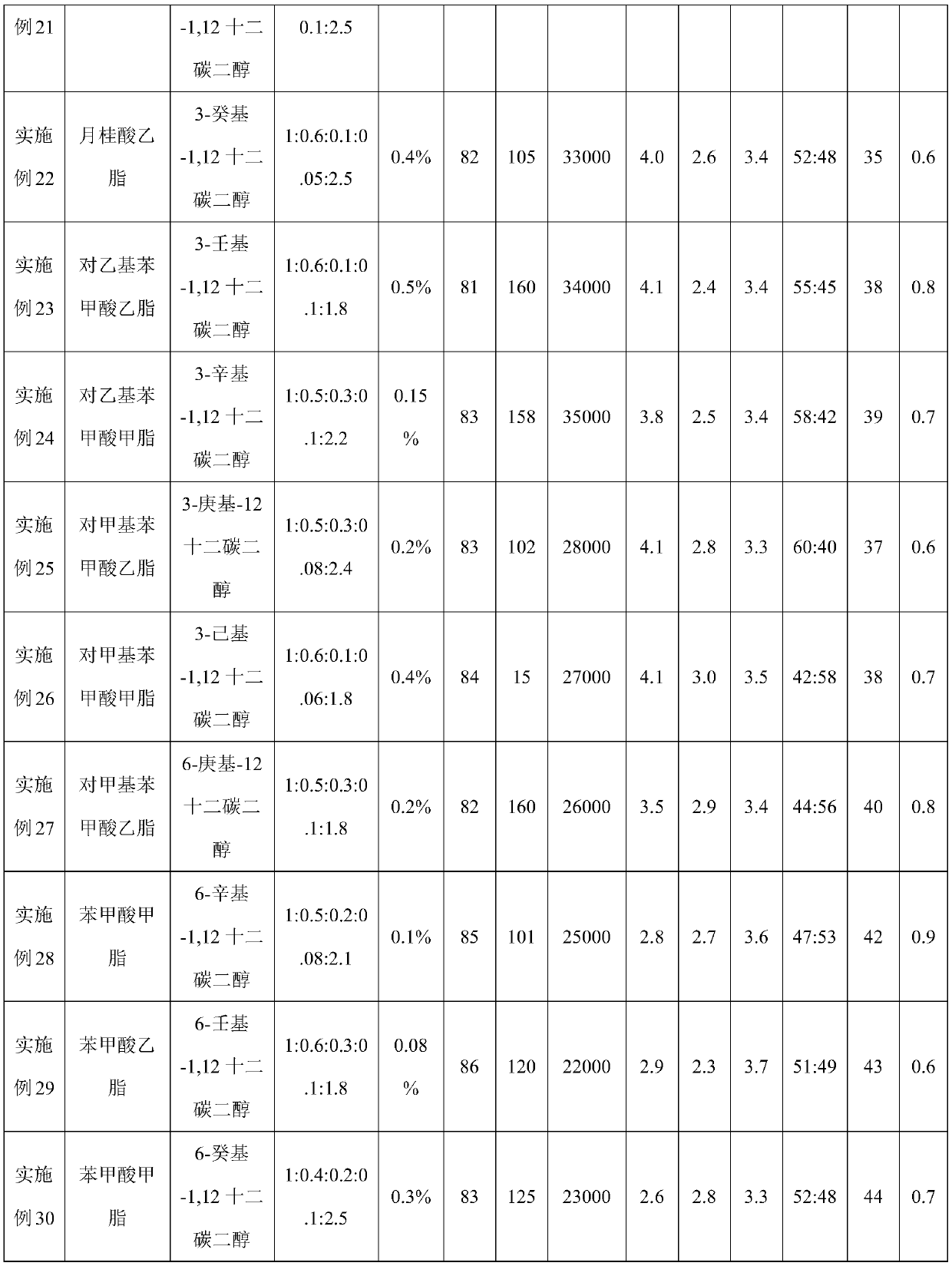

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

Method for preparing modified phenolic resin

The invention relates to a method for preparing a modified phenolic resin for a paper-base copper clad laminate substrate resin. In the method, cardanol is adopted together with an epoxide vegetable oil to modify a phenolic resin, the usage amount of tung oil is reduced considerably, the copper clad laminate manufactured by using the modified phenolic resin as a main resin has the advantages of excellent flexibility, low water absorptivity, high electrical insulation in wet state, low manufacturing cost and the like, and at the same time, a melamine resin is added to further modify the phenolic resin, so the drawback that the phenolic resin changes color due to the light is inhibited obviously and the modified phenolic resin prepared by the method can meet requirements on appearance color.

Owner:福建利豪电子科技股份有限公司

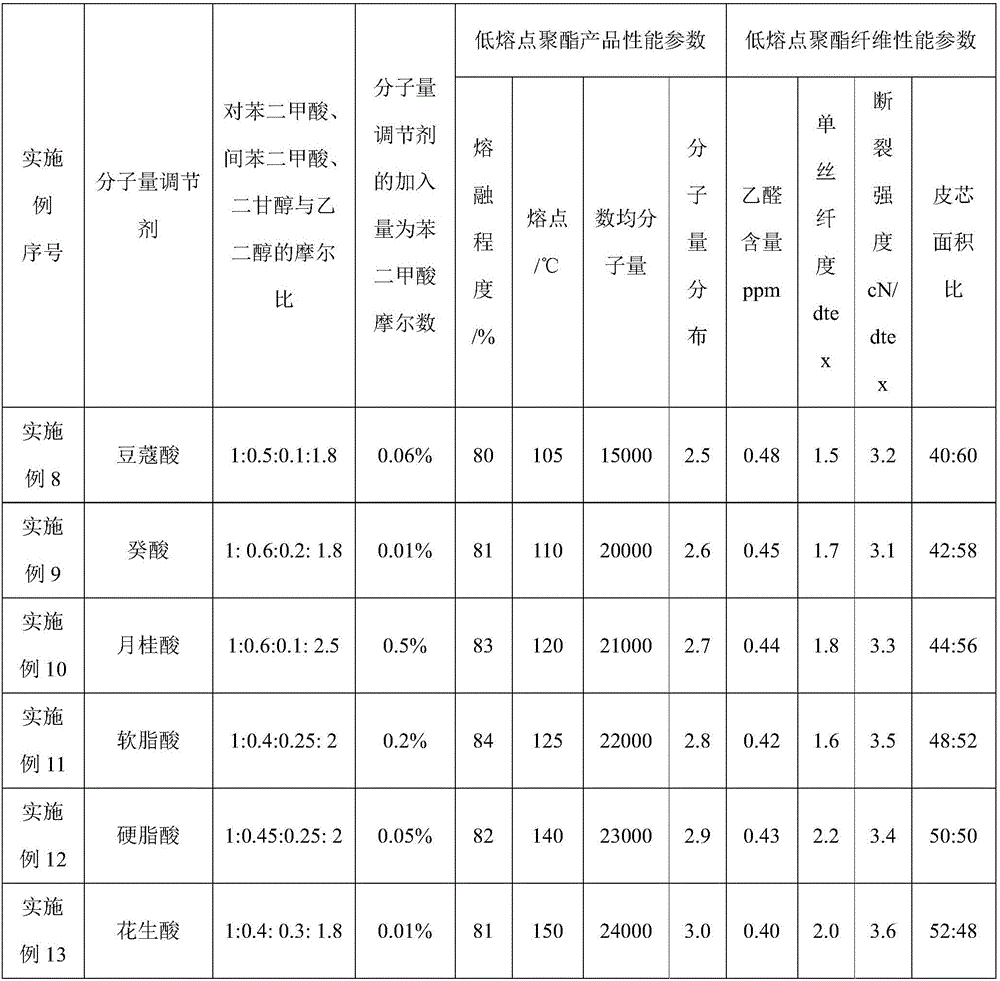

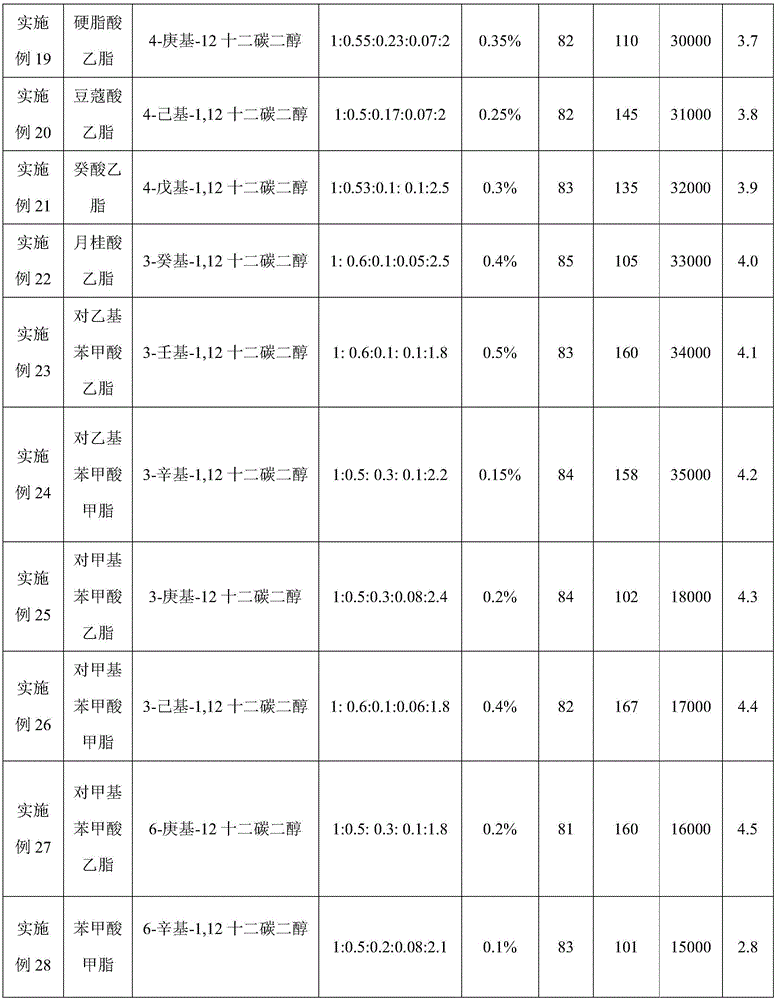

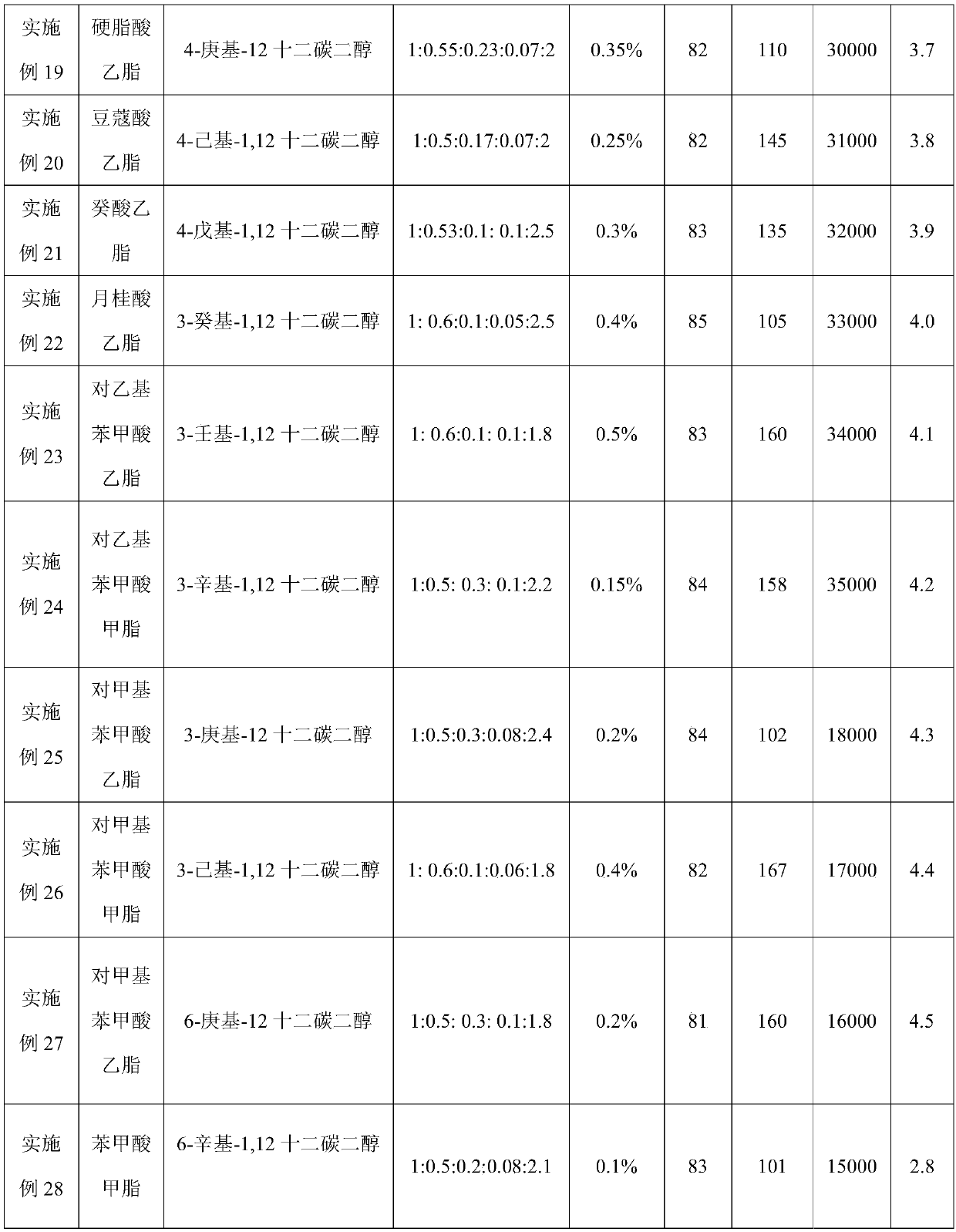

Polyester fiber with low melting point and method for preparing polyester fiber

ActiveCN106757444AIncrease relative volatilityFacilitated DiffusionFilament/thread formingConjugated synthetic polymer artificial filamentsBenzoic acidPolymer science

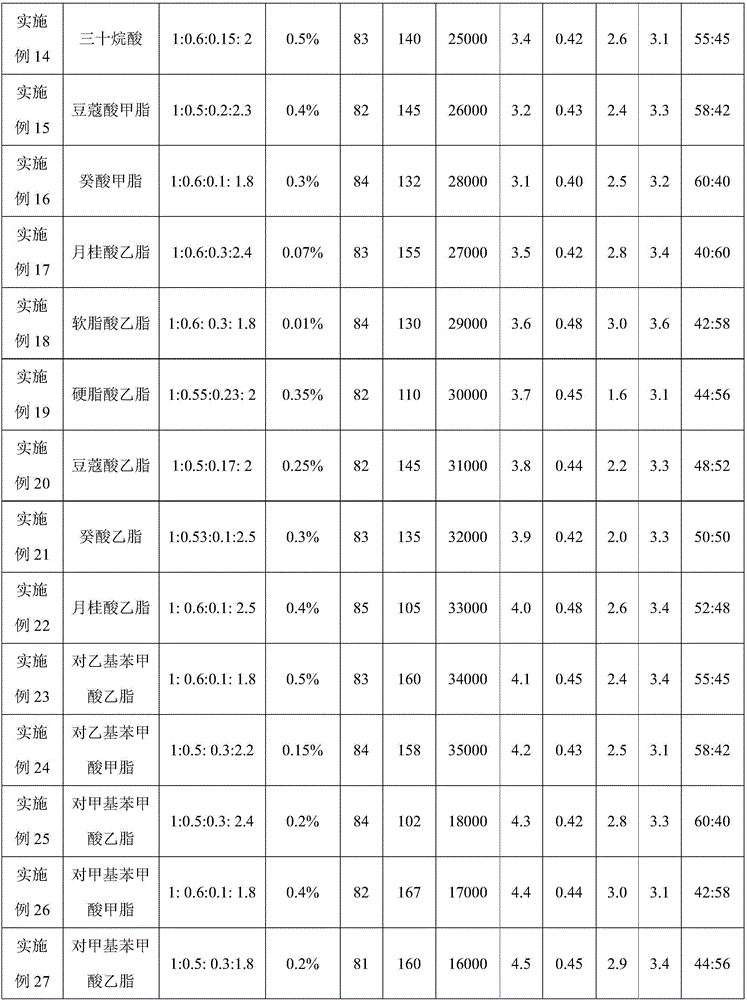

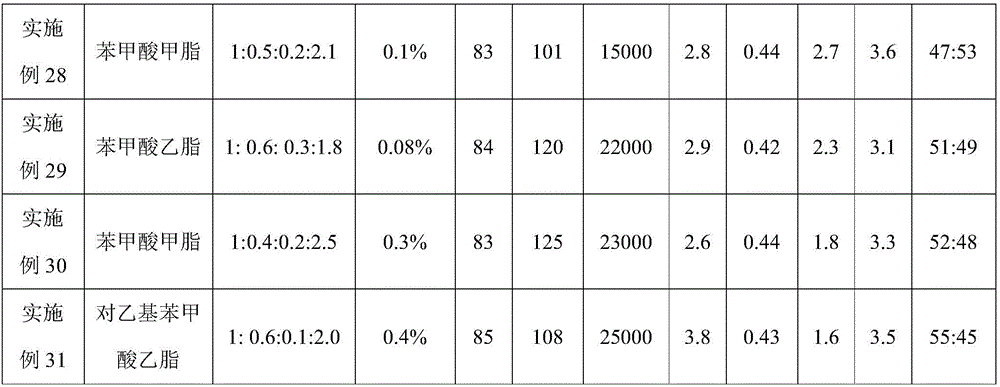

The invention relates to a polyester fiber with a low melting point and a method for preparing the polyester fiber. The polyester fiber with the low melting point is of a skin-core structure, skin layers are made of polyester with a low melting point, and core layers are made of PET (polyethylene terephthalate); the polyester with the low melting point comprises terephthalic acid chain segments, isophthalic acid chain segments, ethylene glycol chain segments, diethylene glycol chain segments and molecular weight regulator end-capping groups; corresponding molecular weight regulators of the molecular weight regulator end-capping groups particularly comprise benzoic acid, p-toluic acid or ethylbenzoic acid, or methyl ester or ethyl ester corresponding to the benzoic acid, the p-toluic acid or the ethylbenzoic acid, or saturated fatty acid or methyl ester or ethyl ester corresponding to the saturated fatty acid; the content of acetaldehyde in the polyester fiber with the low melting point is lower than 0.5 ppm. The method includes steps of polymerizing the polyester with the low melting point and carrying out composite spinning on skin and cores; carrying out back spinning by the aid of drafting-washing processes; carrying out oil-bath drafting by the aid of added sodium sulfite; carrying out crimping, cutting-off and drying to obtain the polyester fiber with the low melting point. The polyester fiber with the low melting point and the method have the advantages that the polyester fiber prepared by the aid of the method has the low melting point and is low in acetaldehyde content.

Owner:扬州富威尔复合材料有限公司

Production technology of core-shell type room-temperature self-crosslinking acrylate emulsion

The invention discloses a production technology of a core-shell type room-temperature self-crosslinking acrylate emulsion. A room-temperature self-crosslinking monomer is introduced by adopting a seed pre-emulsification semi-continuous core-shell emulsion polymerization process; and the acrylate emulsion which has a hard-core and soft-shell structure, is self-crosslinked at room temperature and can be applied to a wood coating is synthesized. The emulsion with a core-shell structure has the advantages of good after-tack resistance, low film-forming temperature, relatively good film-forming property, stability and mechanical property; hard monomers SM and MMA have relatively high glass transition temperature; a film has relatively high hardness, glossiness, weather fastness, anti-fouling performance, cohesion and structure strength; soft monomers BA and 2EHA play an internal plasticization role in a polymerization system; and the film has certain flexibility and adhesiveness.

Owner:QINGDAO SHOUSHENG IND

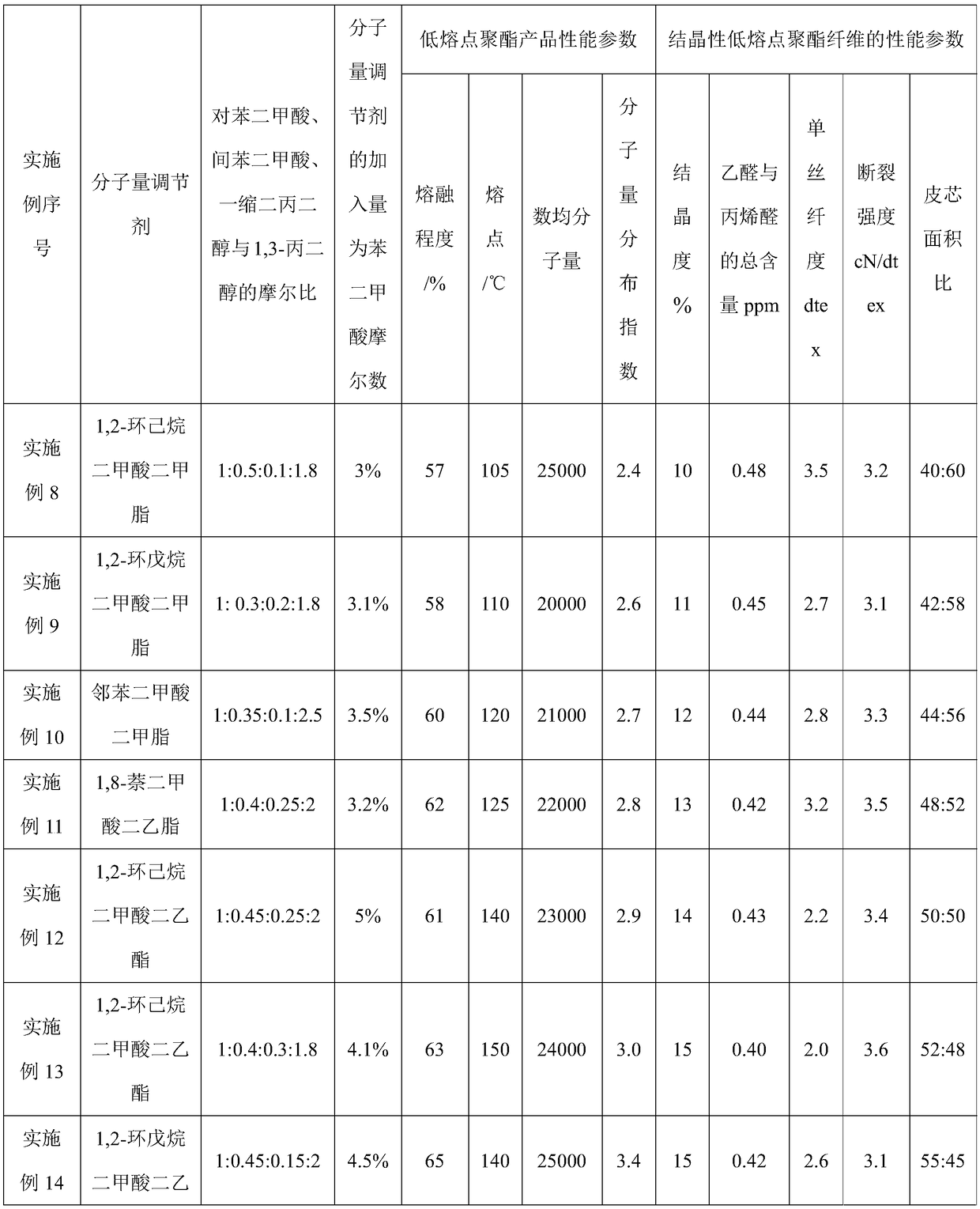

Crystallinity low-melting point polyester fiber and preparation method thereof

ActiveCN106811829AImprove cohesive energyFast curingConjugated synthetic polymer artificial filamentsStretch-spinning methodsFiberPolymer science

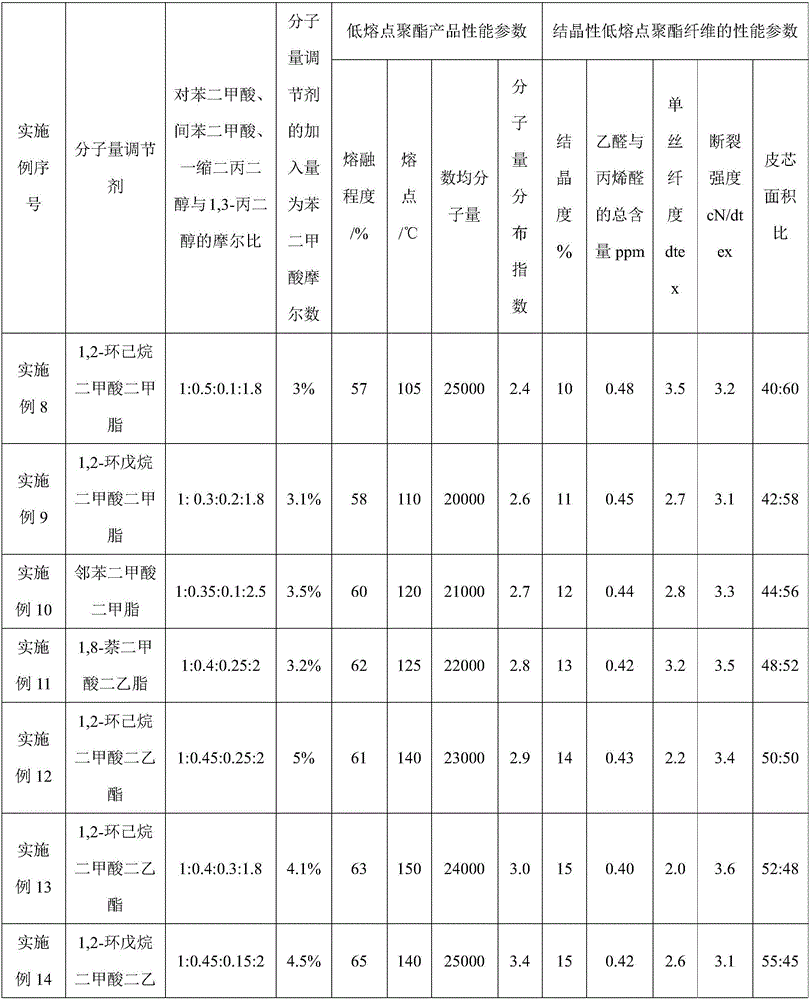

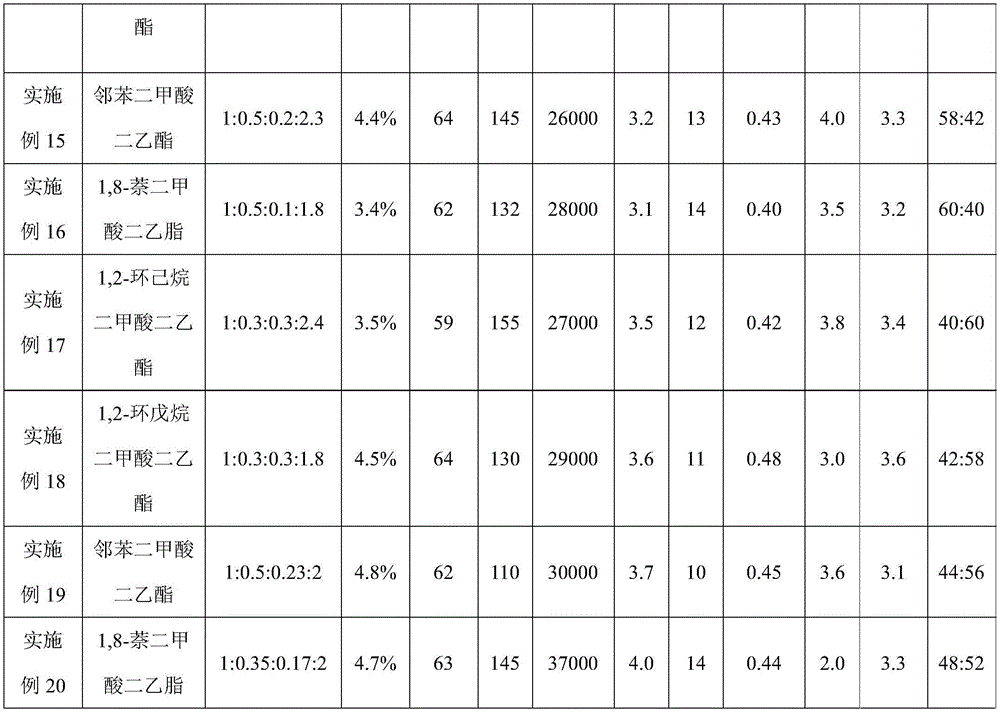

The invention relates to a crystallinity low-melting point polyester fiber and a preparation method thereof; the crystallinity low-melting point polyester fiber is a belt core structure, wherein a belt layer is a low-melting-point polyester, and a core layer is PET; the low-melting point polyester fiber consists of terephthalic acid chain section, isophthalic acid chain section, 1, 3-propylene glycol chain section, dipropylene glycol chain section and molecular weight modifier, wherein the molecular weight modifier corresponding to the molecular weight modifier chain section is 1, 8-naphthalic acid, phthalic acid, 1, 2-cyclopentane dioctyl phthalate, 1, 2-cyclohexane dioctyl phthalate or corresponding dimethyl ester or diethyl ester. The preparation method includes low-melting-point polyester polymerization and belt core composite spinning, wherein post spinning adopts drafting-water washing technique, and drafting adopts oil bath drafting added with sodium sulfite; through rolling, cutting and drying, the crystallinity low-melting point polyester fiber is acquired. The crystallinity low-melting point polyester fiber prepared by the invention is low in melting point, and low in total content of acetaldehyde and acrolein.

Owner:扬州富威尔复合材料有限公司

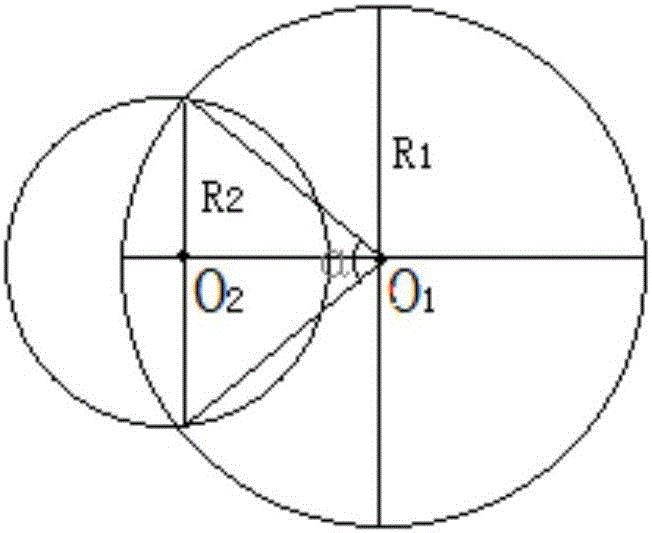

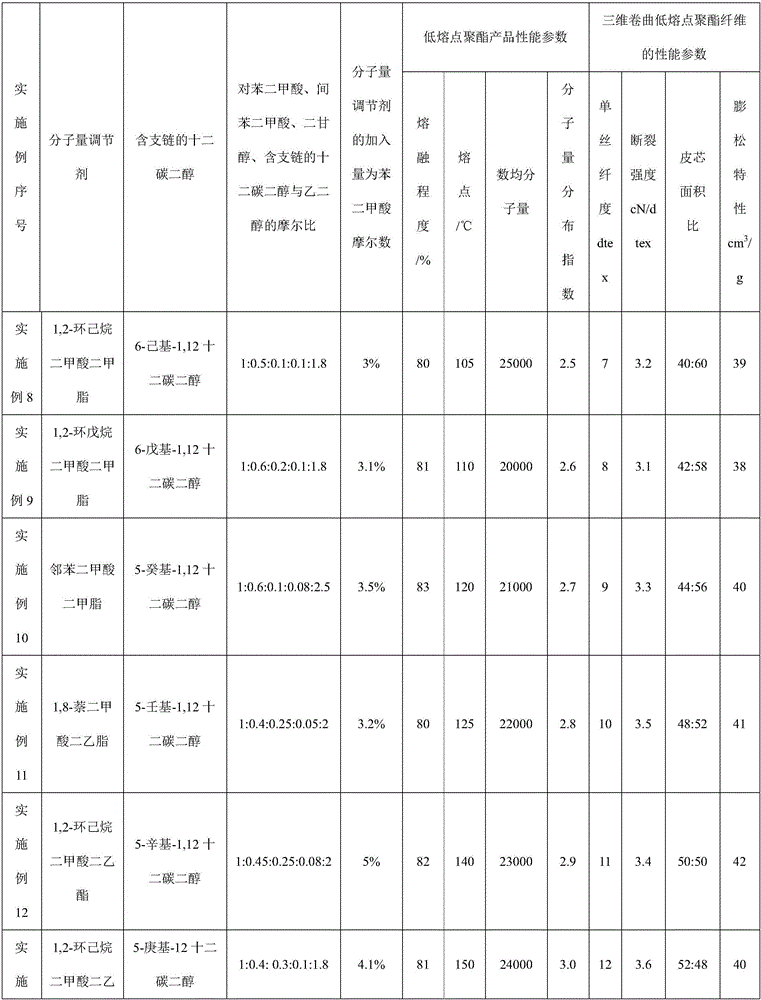

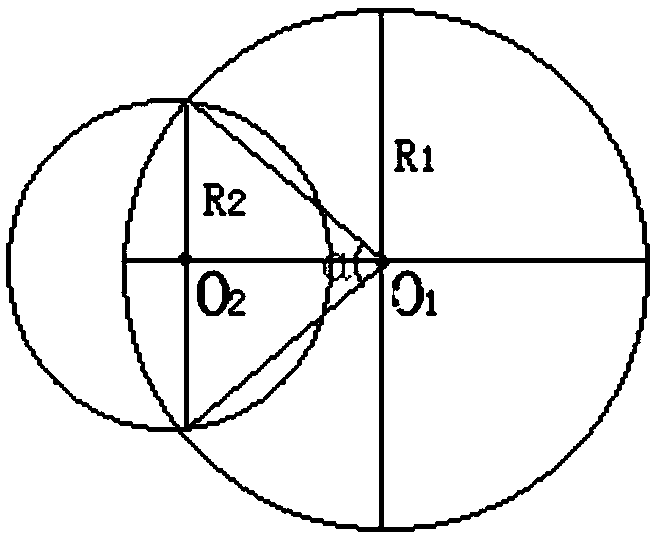

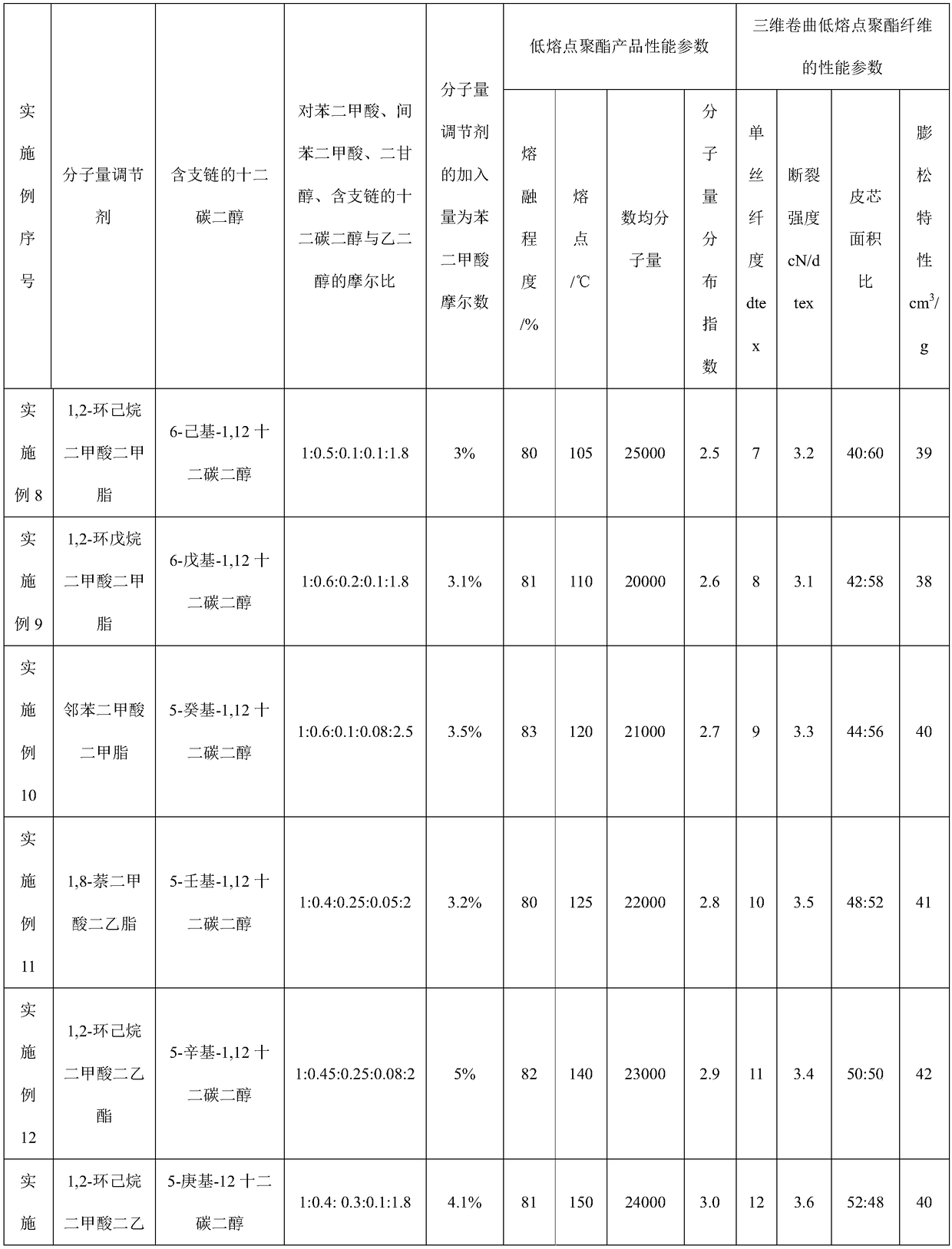

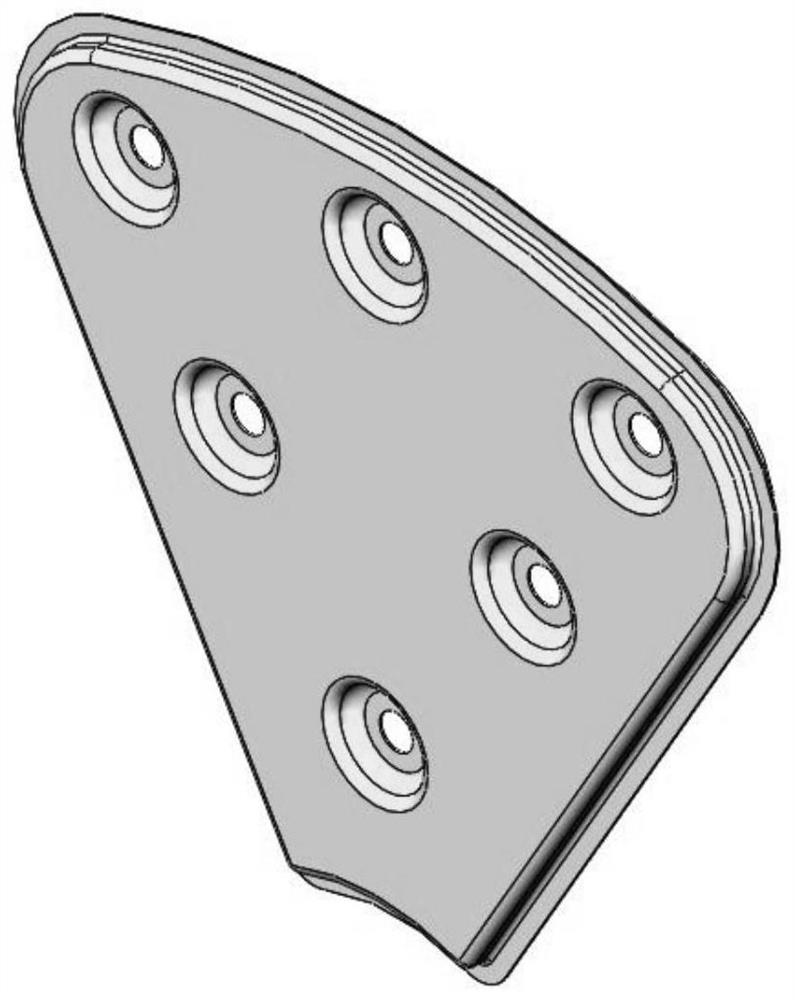

Three-dimensional crimp low-melting-point polyester fiber and preparation method thereof

ActiveCN106811826ALow melting point temperatureFast meltingFilament/thread formingConjugated synthetic polymer artificial filamentsPolyethylene terephthalateDiethylene glycol

The invention relates to a three-dimensional crimp low-melting-point polyester fiber and a preparation method thereof. The three-dimensional crimp low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester, and a core layer is made of PET (polyethylene terephthalate). The low-melting-point polyester is formed by a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier and a branched dodecanediol chain segment. The molecular weight modifier is 1,8-naphthalic acid, phthalic acid, 1,2-cyclopentanedicarboxylic acid, 1,2-cyclohexanedicarboxylic acid or corresponding dimethyl esters or diethyl esters thereof. The preparation method includes steps of low-melting-point polyester polymerization, skin-core composite spinning, crimping, oiling, cutting and drying to obtain the three-dimensional crimp low-melting-point polyester fiber. Core layer spinneret holes of a spinneret plate in the composite spinning process are crescent. The three-dimensional crimp low-melting-point polyester fiber prepared according to the method is low in melting point.

Owner:扬州富威尔复合材料有限公司

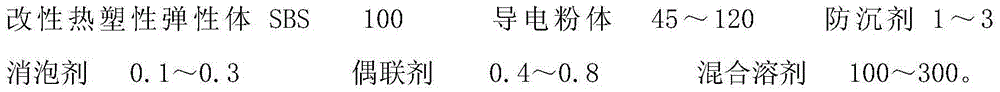

Electromagnetic shielding paint for heat shrink tubing and preparation method of electromagnetic shielding paint

ActiveCN104403480ASuitable for interior and exterior paintingUniform coatingElectrically-conductive paintsSilver platePolyamide

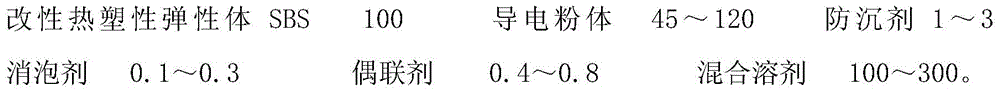

The invention provides electromagnetic shielding paint for a heat shrink tubing. The electromagnetic shielding paint is prepared from raw materials in parts by weight as follows: 100 parts of modified thermoplastic elastomer SBS, 45-120 parts of electric conduction powder, 1-3 parts of an anti-settling agent, 0.1-0.3 parts of an antifoaming agent, 0.4-0.8 parts of a coupling agent and 100-300 parts of a mixed solvent, wherein the modified thermoplastic elastomer SBS is one substance with an S / B value of 30 / 70 or an S / B value of 40 / 60 or a mixture of two substances with the S / B value of 30 / 70and the S / B value of 40 / 60; the electric conduction powder is one or more of silver powder, nickel powder, silver-plated copper powder, silver-plated aluminum powder, silver-plated glass beads, silver-plated nickel powder and nickel-plated graphite; the anti-settling agent is at least one of polyethylene wax or polyamide wax; the antifoaming agent is an organosilicon antifoaming agent; the coupling agent is at least one of a titanate coupling agent or a silane coupling agent; and the mixed solvent is prepared by mixing 120# solvent gasoline and methylbenzene at the mass ratio of (8:1)-(2:1).

Owner:JINAN ZHONGZHENG NEW MATERIAL

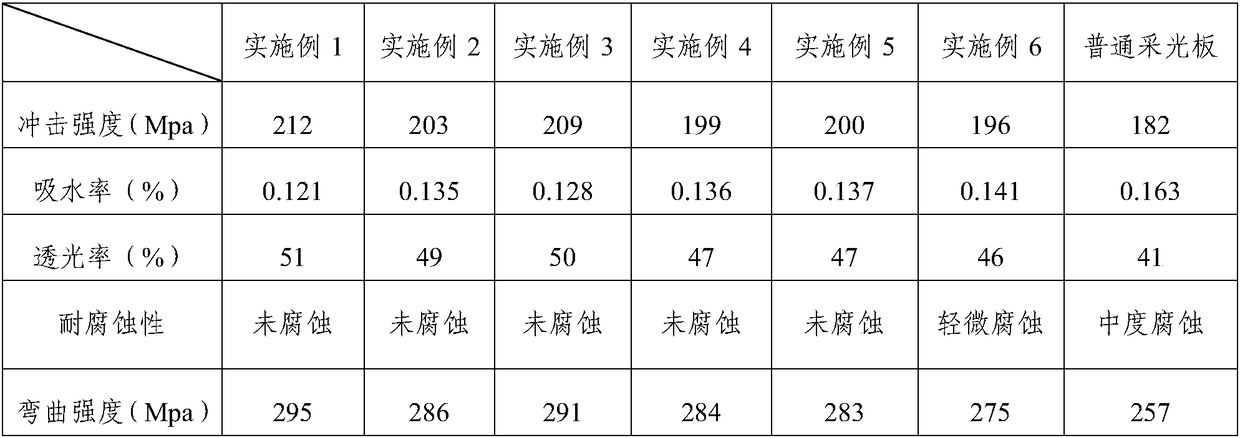

Weather-resistant composite material for lighting, lighting plate and preparation method thereof

InactiveCN108587057AGood weather resistanceImproves UV resistanceSynthetic resin layered productsBuilding componentsFiberYarn

A weather-resistant composite material for lighting is prepared from the following components in parts by weight: 10-15 parts of xylene formaldehyde resin, 10-15 parts of phenolic resin, 10-15 parts of vinyl ester resin, 10-15 parts of isophthalate poIyesler resin, 3-8 parts of methacrylic acid, 3-8 parts of ethylenediamine tetraacetic acid, 2-5 parts of an ultraviolet absorbent, 1-3 parts of a curing agent, 0.5-1.5 parts of an accelerant, 0.8-2 parts of a flame retardant, 0.8-2.5 parts of antioxidant and 20-30 parts of glass fiber yarns. The weather-resistant composite material for lighting disclosed by the invention has good corrosion resistance, ultraviolet resistance and the like, and the prepared lighting plate has good impact strength, corrosion resistance and the like, and effectively enhances the weather resistance of the lighting plate.

Owner:安徽宏志建材科技有限公司

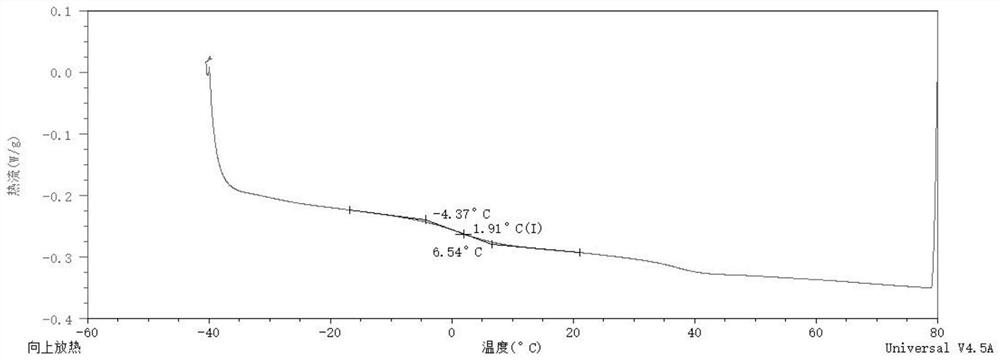

Ultra-short polyester fiber with low melting point and method for preparing ultra-short polyester fiber

ActiveCN106811827AAvoid bondingGood dispersionFibre typesFilament/thread formingFiberPolyethylene terephthalate glycol

The invention relates to an ultra-short polyester fiber with a low melting point and a method for preparing the ultra-short polyester fiber. The ultra-short polyester fiber with the low melting point is of a skin-core structure. Skin layers are made of polyester with a low melting point, and core layers are made of PET (polyethylene terephthalate); the polyester with the low melting point comprises terephthalic acid chain segments, isophthalic acid chain segments, ethylene glycol chain segments, diethylene glycol chain segments, molecular weight regulator chain segments and dodeca-carbon diol chain segments with branch chains; molecular weight regulators corresponding to the molecular weight regulator chain segments are particularly monoacid series or binary acid series. The method includes steps of polymerizing the polyester with the low melting point and carrying out skin-core composite spinning; carrying out back-spinning by the aid of drafting processes; carrying out oiling, cutting-off and drying to obtain the ultra-short polyester fiber with the low melting point. The ultra-short polyester fiber with the low melting point and the method have the advantages that the initial melting point of the ultra-short polyester fiber prepared by the aid of the method is reduced to a certain extent, the melting speed of the ultra-short polyester fiber is increased, the ultra-short polyester fiber can be immediately molten at the corresponding temperatures, and good melting effects can be realized.

Owner:扬州富威尔复合材料有限公司

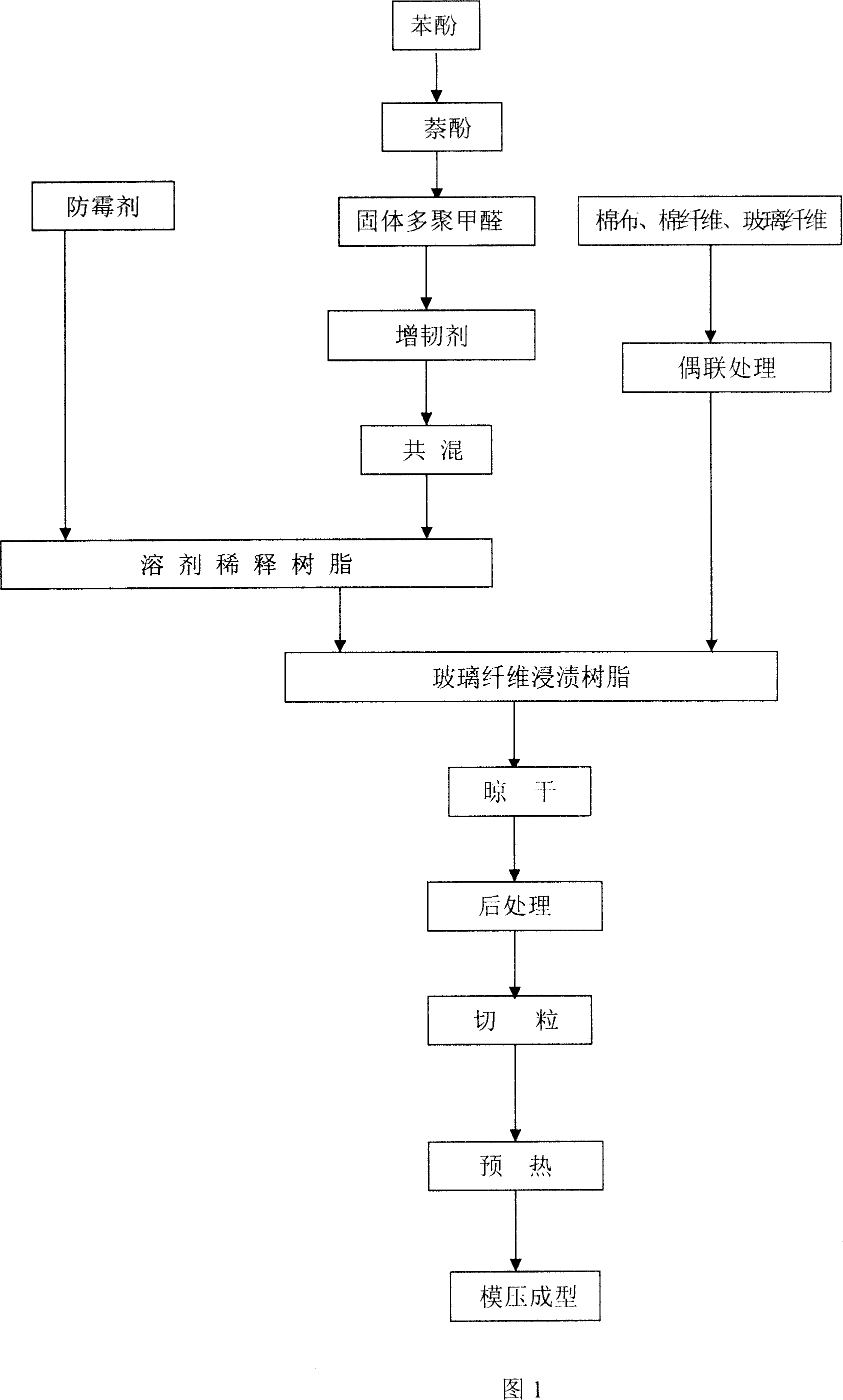

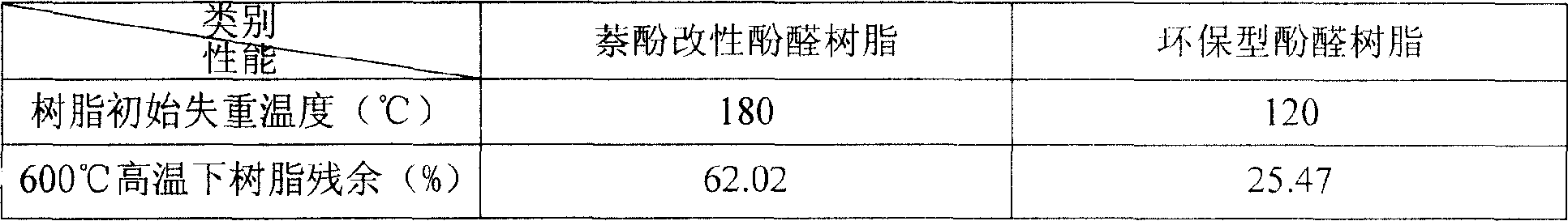

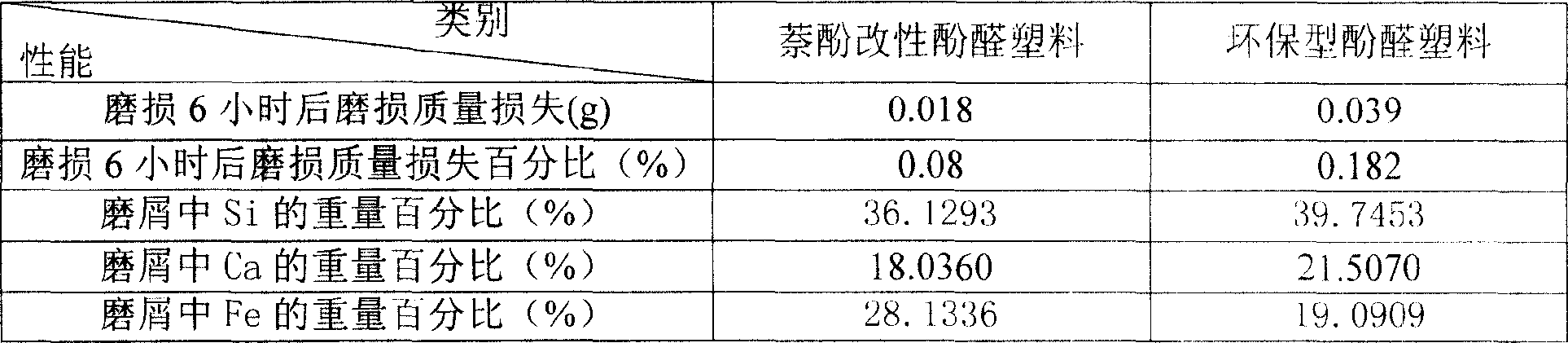

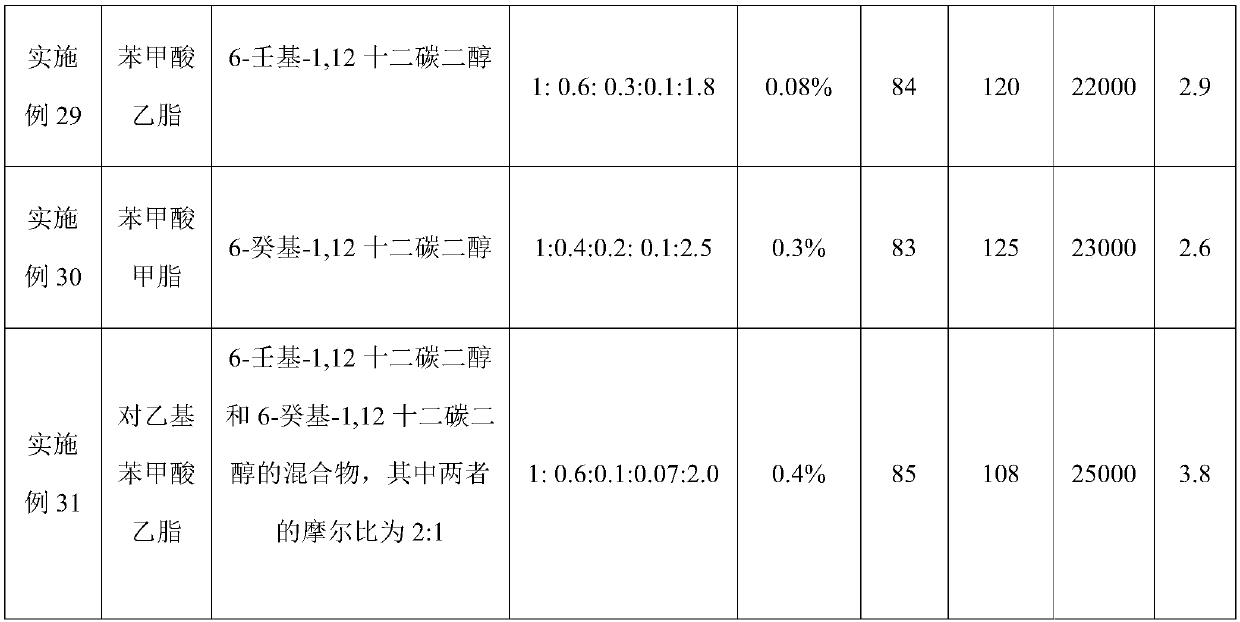

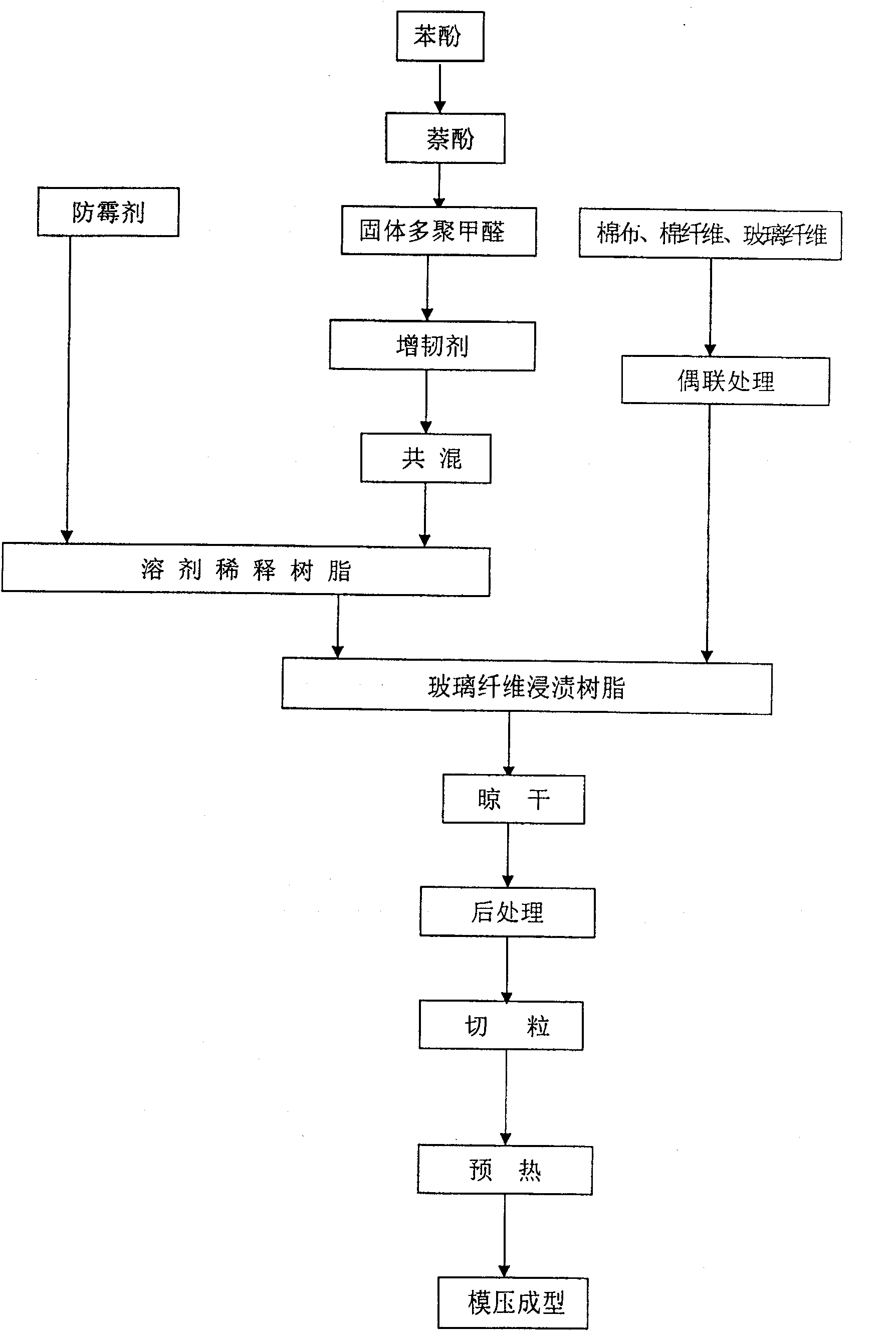

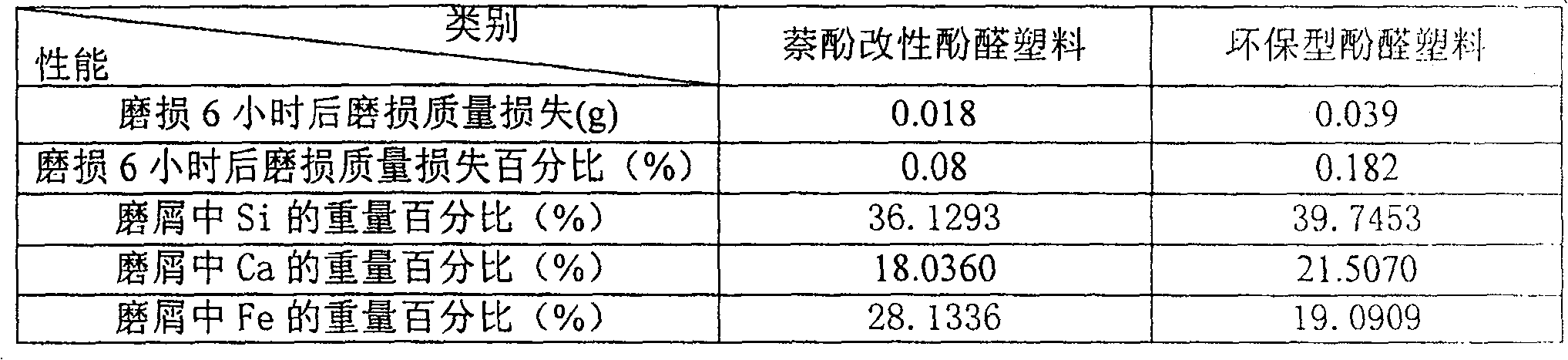

Naphthol-modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The technical characteristics lie on the ratio of the components: 100 phenol, solid paraform 40 - 45, naphthol 10 - 15 and fiberglass 55 -60, polysulfone 10- 20, sodium pentachlorophenate 2 - 5, solvents 94 -100. Through the stir conditions adding naphthol into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

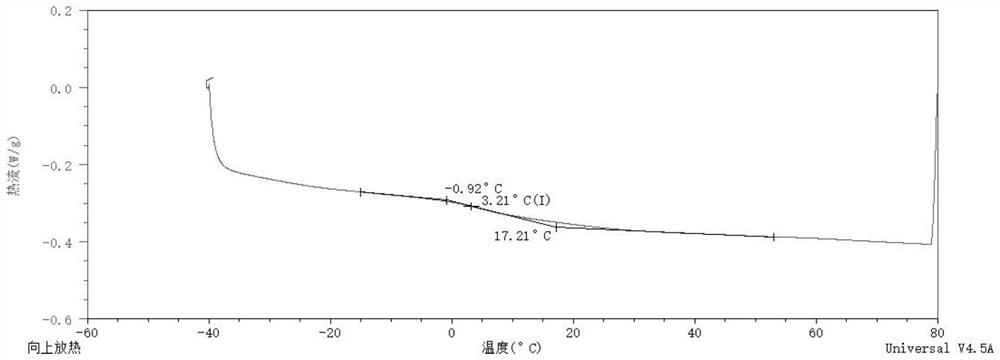

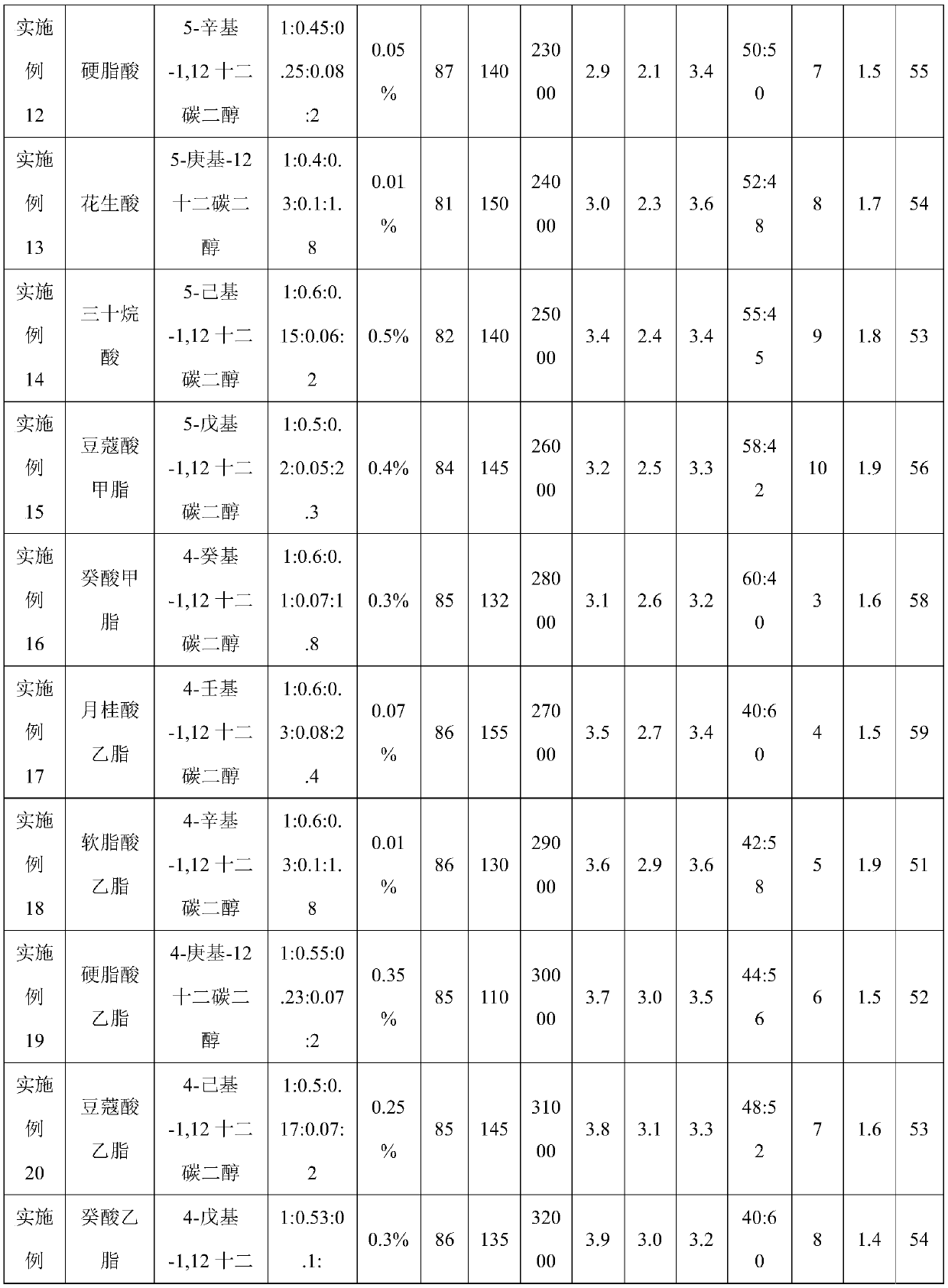

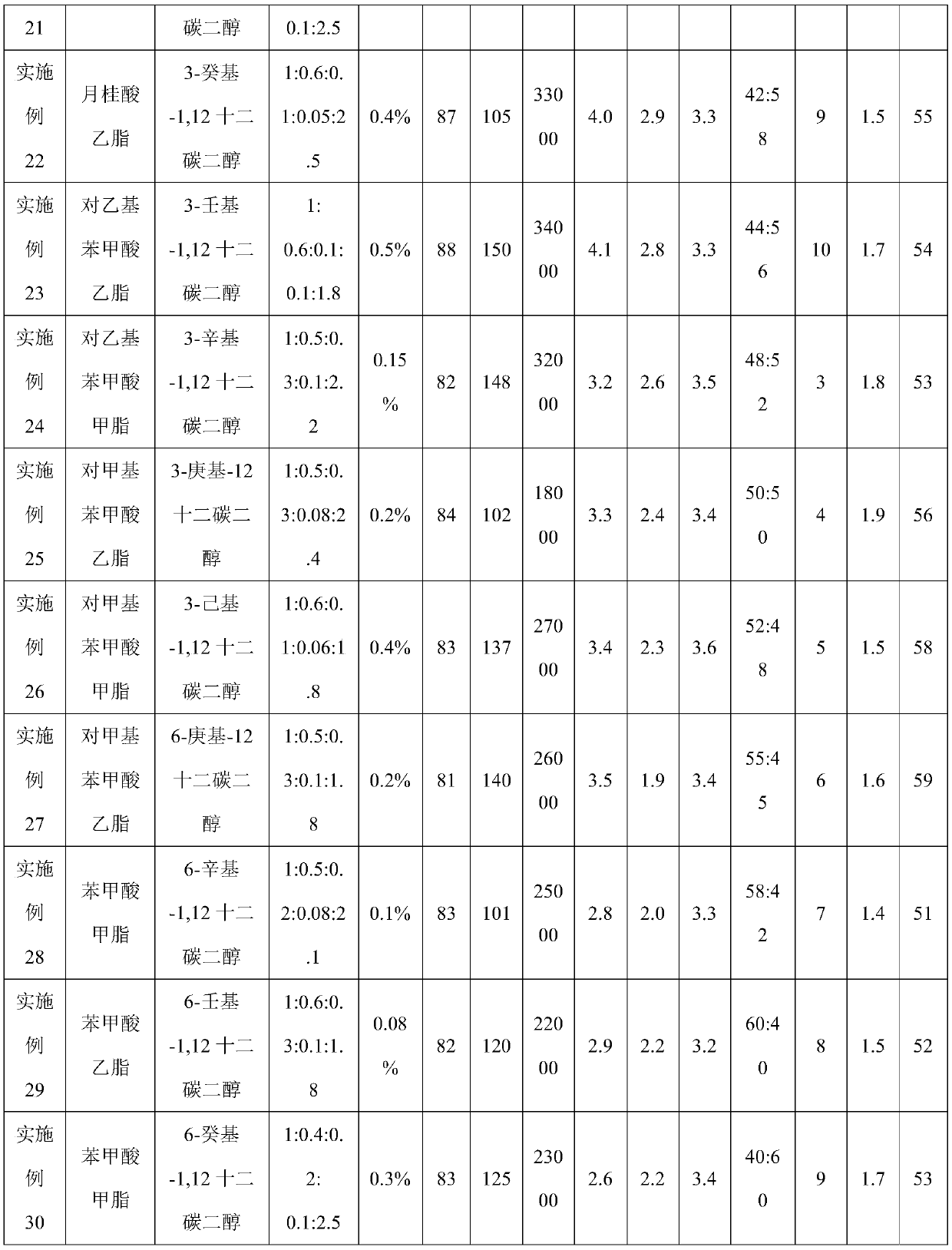

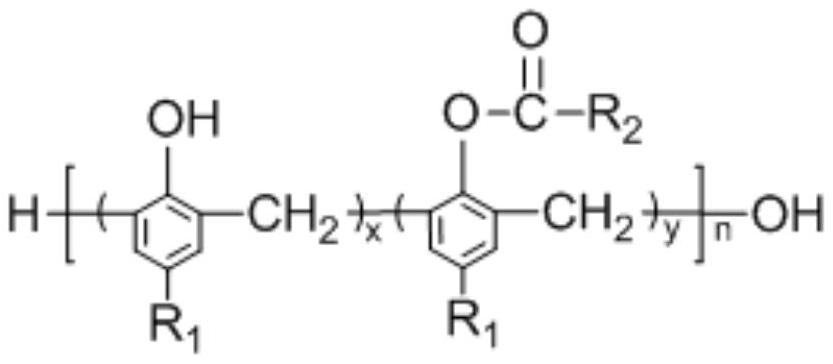

Low-melting point polyester and preparation method thereof

The invention relates to a low-melting point polyester and a preparation method of the low-melting point polyester. The low-melting point polyester comprises a terephthalic acid chain segment, a m-phthalic acid chain segment, an ethanediol chain segment, a diethylene glycol chain segment, a molecular weight modifier capping group and a branched chain containing codlemone chain segment; a molecular weight modifier corresponding to the molecular weight modifier capping group is specifically benzoic acid, p-toluylic acid or p-ethylbenzoic acid, or corresponding methyl ester or ethyl ester of benzoic acid, p-toluylic acid or p-ethylbenzoic acid, or saturated fatty acid or corresponding methyl ester or ethyl ester of the saturated fatty acid; the saturated fatty acid refers to a fatty acid with the carbon number of 9-30. The preparation method comprises the following steps: (1) enabling the terephthalic acid, the m-phthalic acid, the ethanediol, the diethylene glycol, the molecular weight modifier and the branched chain containing codlemone to have an esterification reaction; (2) then conducting condensation polymerization to prepare the low-melting point polyester. The molecular weight distribution of the prepared low-melting point polyester is relatively wide, the melting point is further reduced, and the melting speed is faster.

Owner:扬州富威尔复合材料有限公司

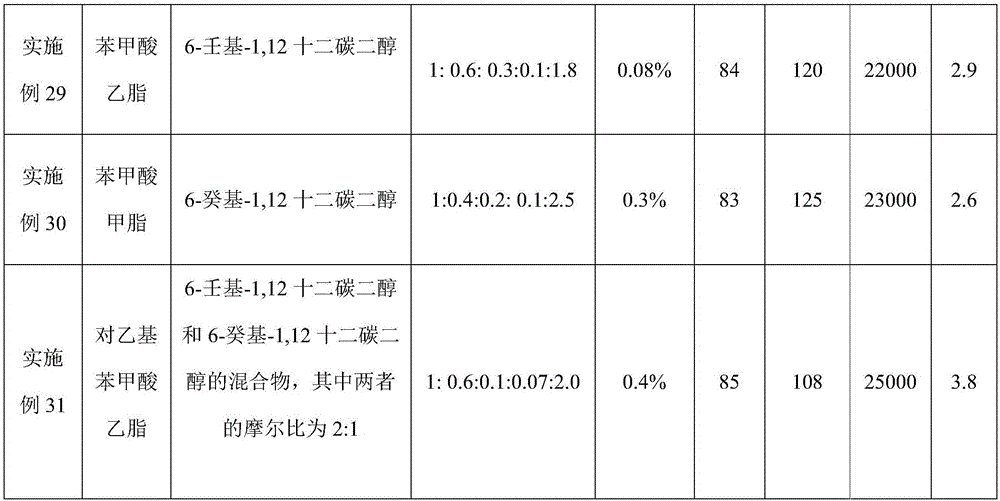

UV-cured hot-melt acrylate pressure-sensitive adhesive and electrical adhesive tape prepared from same

InactiveCN112480831AReduce interactionImprove initial tack performanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceAdhesive belt

The invention provides a UV-cured hot-melt acrylate pressure-sensitive adhesive and an electrical adhesive tape prepared from the same, and the UV-cured hot-melt acrylate pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 20-60 parts of acrylic resin, 20-40 parts of a tackifying resin, 2-15 parts of a reactive diluent, 2-15 parts of an alkene monomer, 2-10parts of a softener and 0.1-2.0 parts of an antioxidant. The prepared pressure-sensitive adhesive and the prepared electrical adhesive tape have excellent initial viscosity, peel strength and persistent viscosity, and meanwhile, the acrylic resin in the pressure-sensitive adhesive is obtained by pre-polymerizing a polymerizable macromolecular photoinitiator, so that the problems that the photoinitiator is residual, photolysis fragments are easy to migrate and volatilize, a cured product is easy to age and yellow, smell and toxicity are easy to occur and the like are solved.

Owner:广东硕成科技股份有限公司

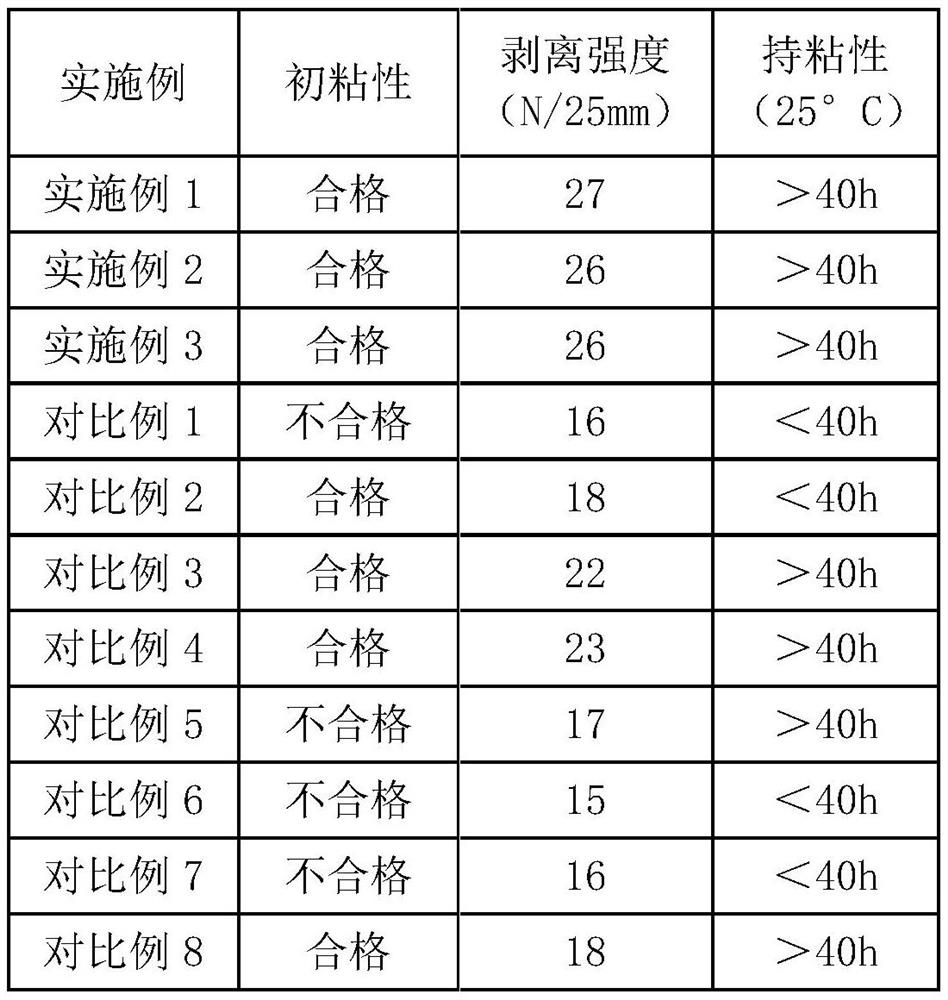

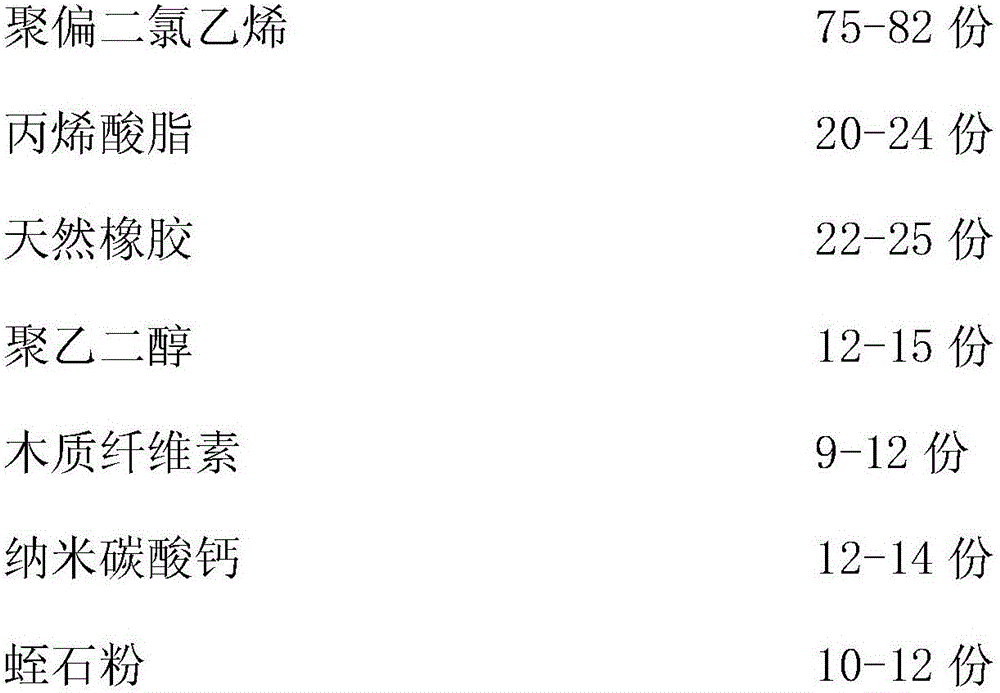

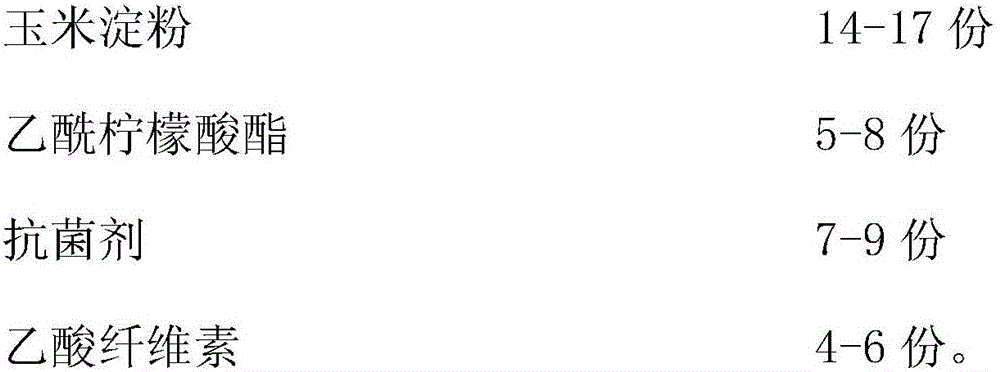

Packaging material used in drugs and a preparing method thereof

The invention relates to a packaging material used in drugs and a preparing method thereof. The packaging material is prepared from, by weight, 72-85 parts of polyvinylidine chloride, 18-26 parts of acrylic ester, 20-28 parts of natural rubber, 10-17 parts of polyethylene glycol, 8-13 parts of lignocellulose, 10-16 parts of nano calcium carbonate, 7-13 parts of vermiculite power, 12-17 parts of corn starch, 3-8 parts of acetyl citrate, 5-9 parts of antibacterial agent and 2-6 parts of cellulose acetate; the packaging material used in the drugs use polyvinylidine chloride as a main raw material, has a good effect of obstructing gases in air such as oxygen, vapour, carbon dioxide, has a good damp resistant property, and good transparency and good heat-resistant and cold-resistant properties; the adding of acrylic ester and natural rubber plays a role of plasticizing the internal parts; acetyl citrate is adopted as a plasticizer, thus the packaging material used in the drugs is green and environmentally friendly, and poisonless and tasteless; through the adoption of the antibacterial agent, the packaging material used in the drugs has a strong antimicrobial effect and an enduring bacteria-resistant effect, and thus expiration date of the drugs is prolonged.

Owner:安徽省天乐塑业有限公司

Method for preparing modified phenolic resin

The invention relates to a method for preparing a modified phenolic resin for a paper-base copper clad laminate substrate resin. In the method, cardanol is adopted together with an epoxide vegetable oil to modify a phenolic resin, the usage amount of tung oil is reduced considerably, the copper clad laminate manufactured by using the modified phenolic resin as a main resin has the advantages of excellent flexibility, low water absorptivity, high electrical insulation in wet state, low manufacturing cost and the like, and at the same time, a melamine resin is added to further modify the phenolic resin, so the drawback that the phenolic resin changes color due to the light is inhibited obviously and the modified phenolic resin prepared by the method can meet requirements on appearance color.

Owner:福建利豪电子科技股份有限公司

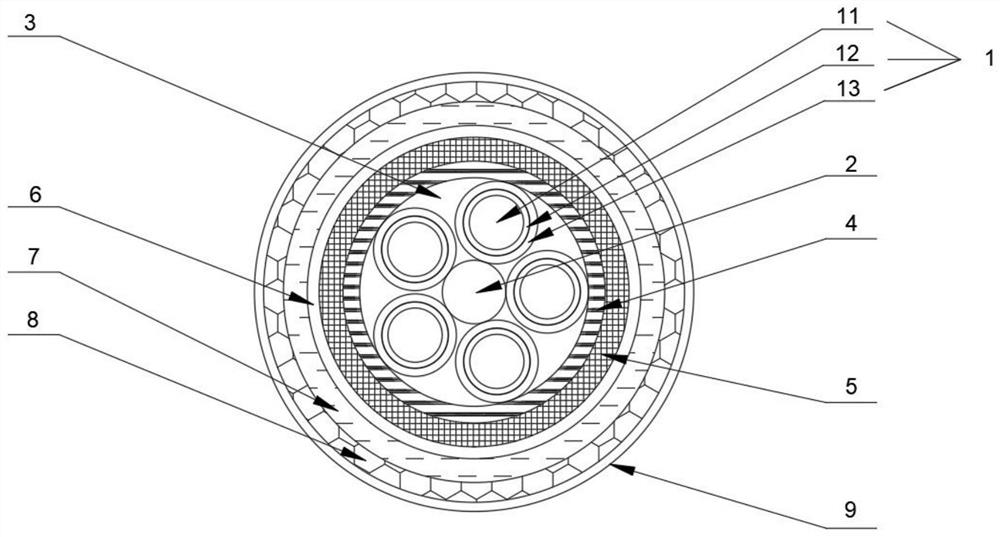

Environment-friendly low-smoke halogen-free flame-retardant power cable

ActiveCN112951500AHigh glass transition temperatureLower storage modulusRubber insulatorsPower cables with screens/conductive layersTinningCable transmission

The invention provides an environment-friendly low-smoke halogen-free flame-retardant power cable with an anti-ultraviolet layer. The cable comprises a wire core assembly and a central filling rope from inside to outside, the wire core assembly is twisted around the central filling rope in a same direction, and the wire core assembly comprises a wire core body. The outer surface of the wire core body is coated with an inner shielding layer, the outer surface of the inner shielding layer is coated with an insulating layer, and the outer surface of the insulating layer is fixedly connected with an outer shielding layer. A fireproof filler is filled between the outer shielding layer and the insulating layer, the outer surface of the outer shielding layer is fixedly connected with an inner sheath layer, and the outer surface of the inner sheath layer is sequentially connected with an armored layer, a fireproof layer, an outer sheath layer and an anti-ultraviolet layer. According to the present invention, the ultraviolet-proof performance of the cable provided by the invention is relatively higher in glass transition temperature, and the brittle-tough transition is realized during ultraviolet radiation, so that the tensile strength of the cable is improved, partial aging side effects are counteracted, and further the cable has relatively higher ultraviolet-proof capability; the outer shielding layer is formed by weaving tin-plated steel wires and aramid fibers in a mixed manner, and the tin-plated steel wires are used for shielding interference, so that the excellent transmission efficiency of the cable is guaranteed.

Owner:湖南华菱线缆股份有限公司

Wear-resistant migration-resistant high elastic foot pad material

The invention discloses a wear-resistant migration-resistant high elastic foot pad material which is prepared from the following raw materials in parts by weight: polyvinyl chloride, methyl hydrogen-containing silicone resin, allyl glycidyl ether, vinyl ester resin, toluene, c toluene, a chloroethylene-butyl acrylate copolymer, isobutyl rubber, a plasticizer, an anti-aging agent, a stabilizer, anaccelerant, a crosslinking agent, carbon black, serpentine powder, illite powder, sorbitol, chloroplatinic acid and ethanol. The wear-resistant migration-resistant high elastic foot pad material disclosed by the invention has the characteristics of being light to pave, novel in appearance and the like, has good wear resistance, slip resistance, waterproofness, proper toughness, stiffness and elasticity, is good in integral texture, is cold-resistant, anti-aging, fold-resistant, and good in gas permeability. The material is prepared by mixing rubber and plastic, so that the cost is lowered andthe material has a faux leather texture.

Owner:陈桂芳

A kind of low melting point polyester and preparation method thereof

Owner:扬州富威尔复合材料有限公司

Naphthol-modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The technical characteristics lie on the ratio of the components: 100 phenol, solid paraform 40 - 45, naphthol 10 - 15 and fiberglass 55 -60, polysulfone 10- 20, sodium pentachlorophenate 2 - 5, solvents 94 -100. Through the stir conditions adding naphthol into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

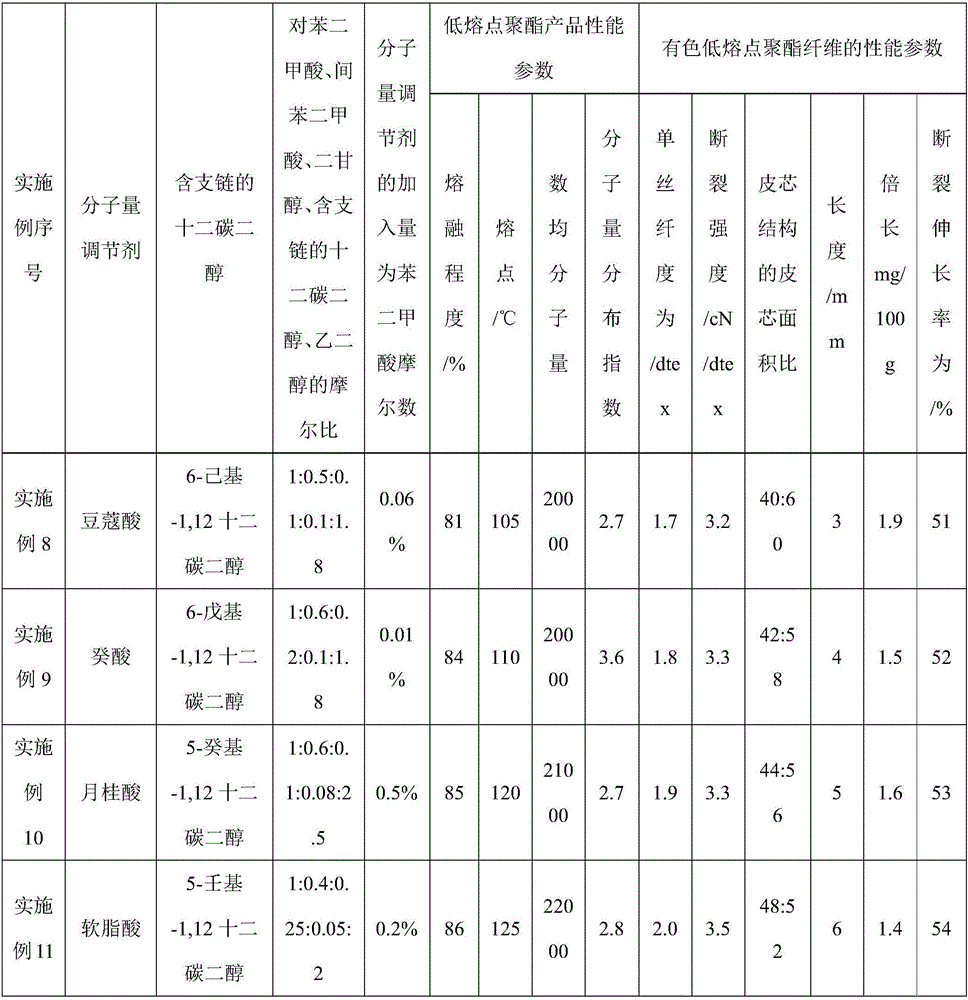

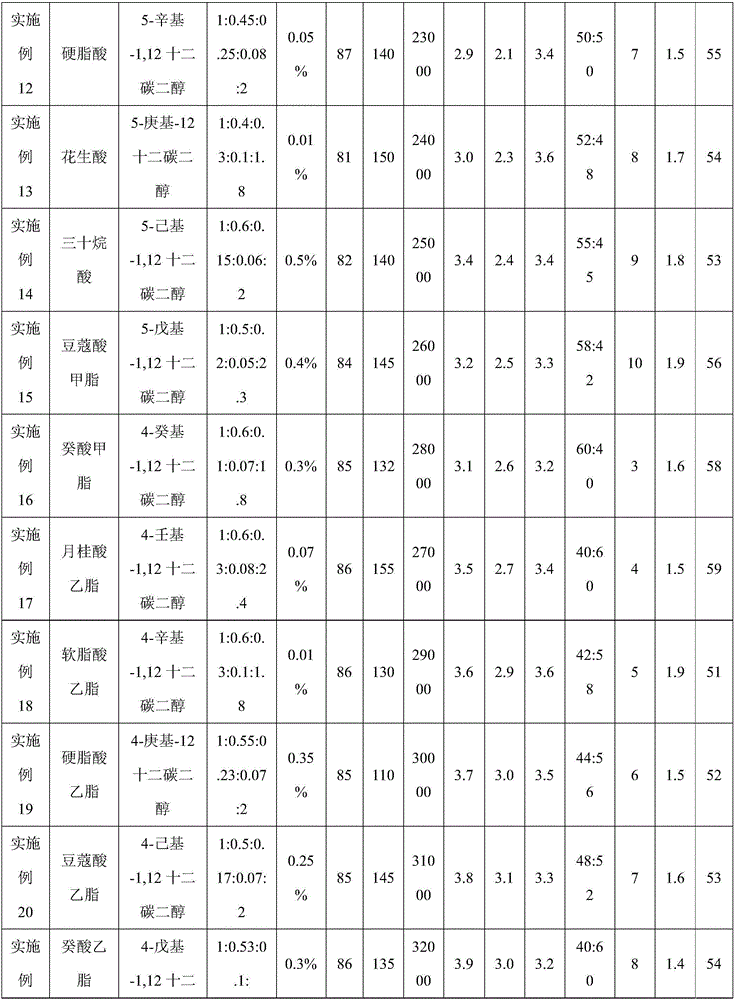

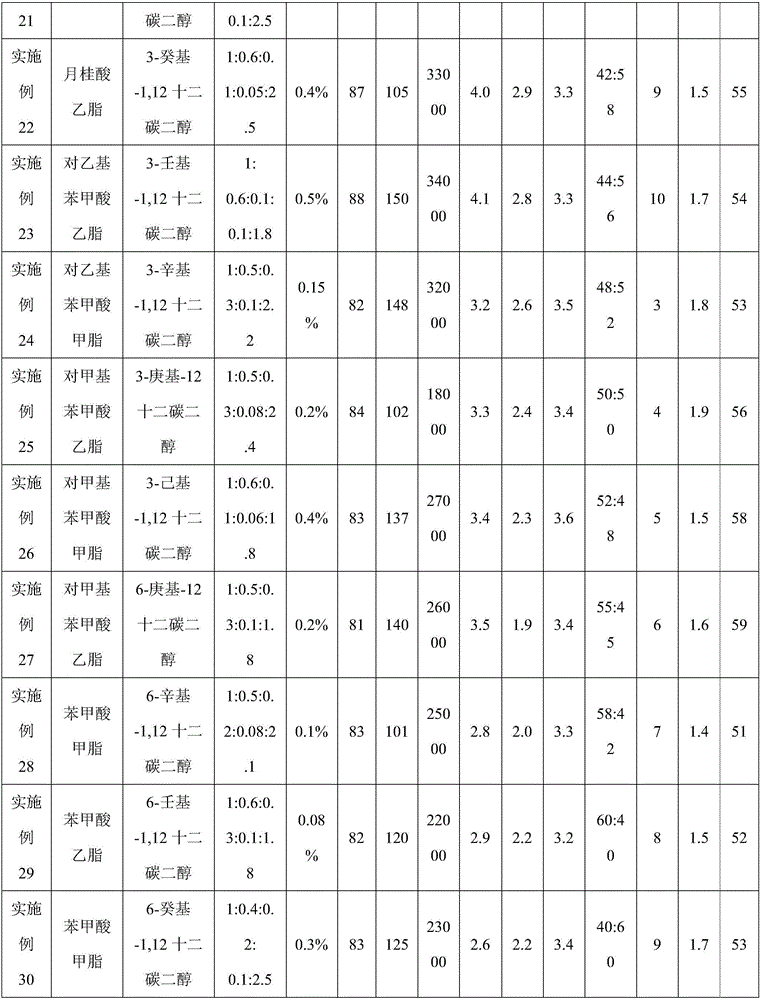

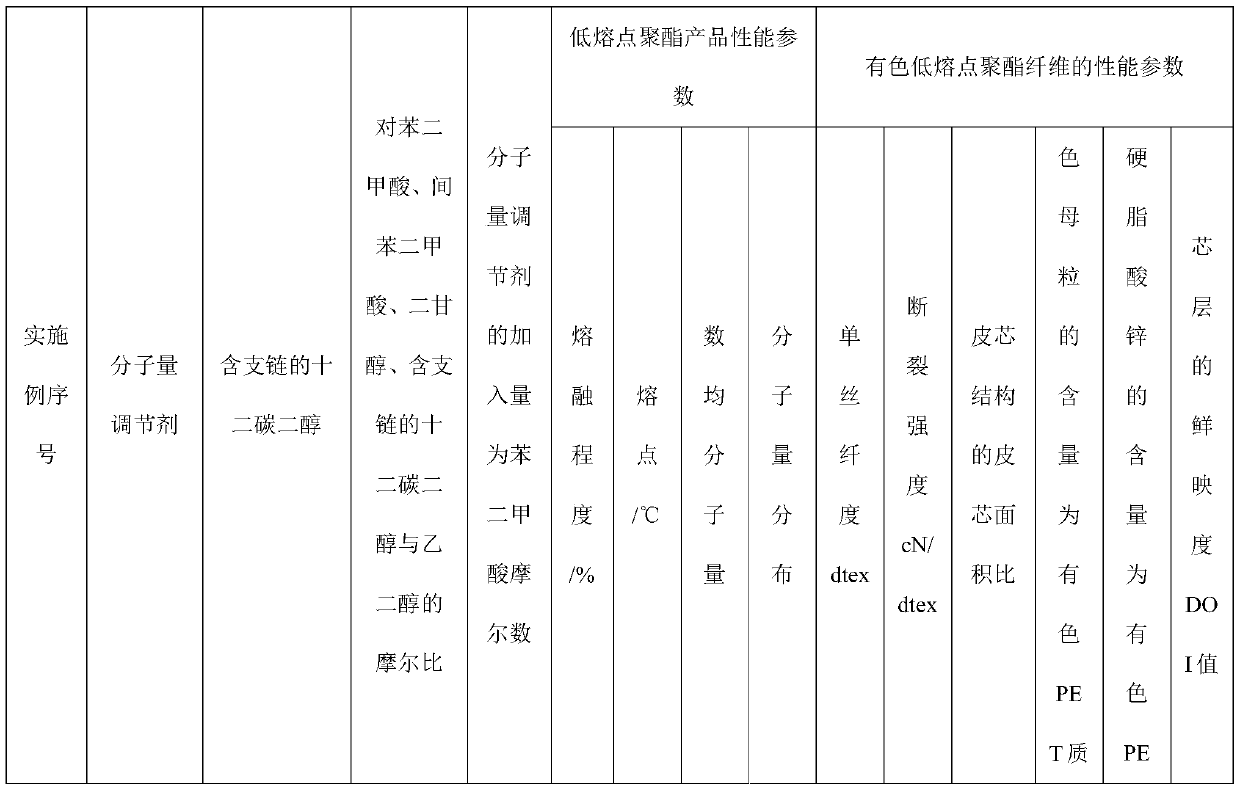

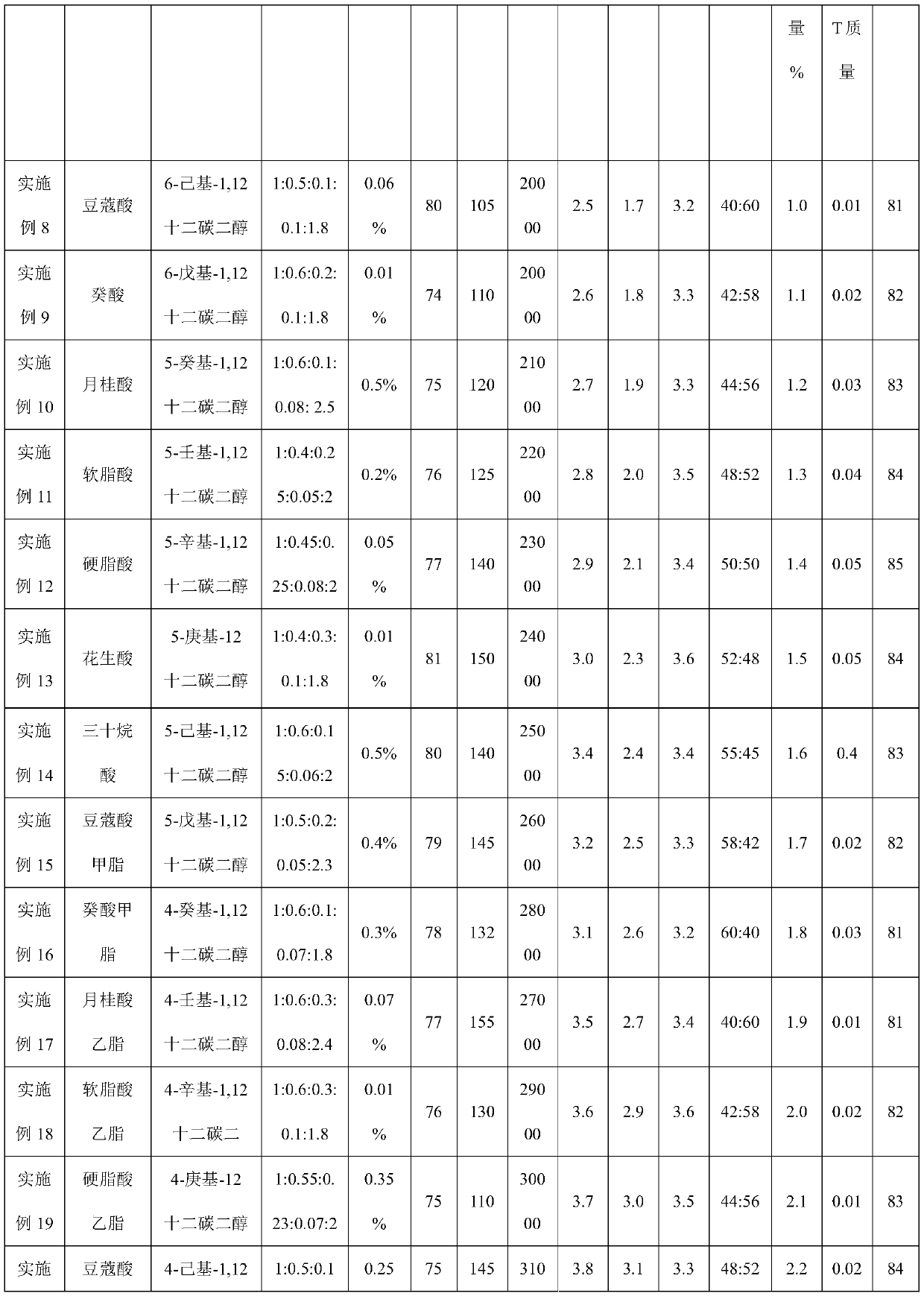

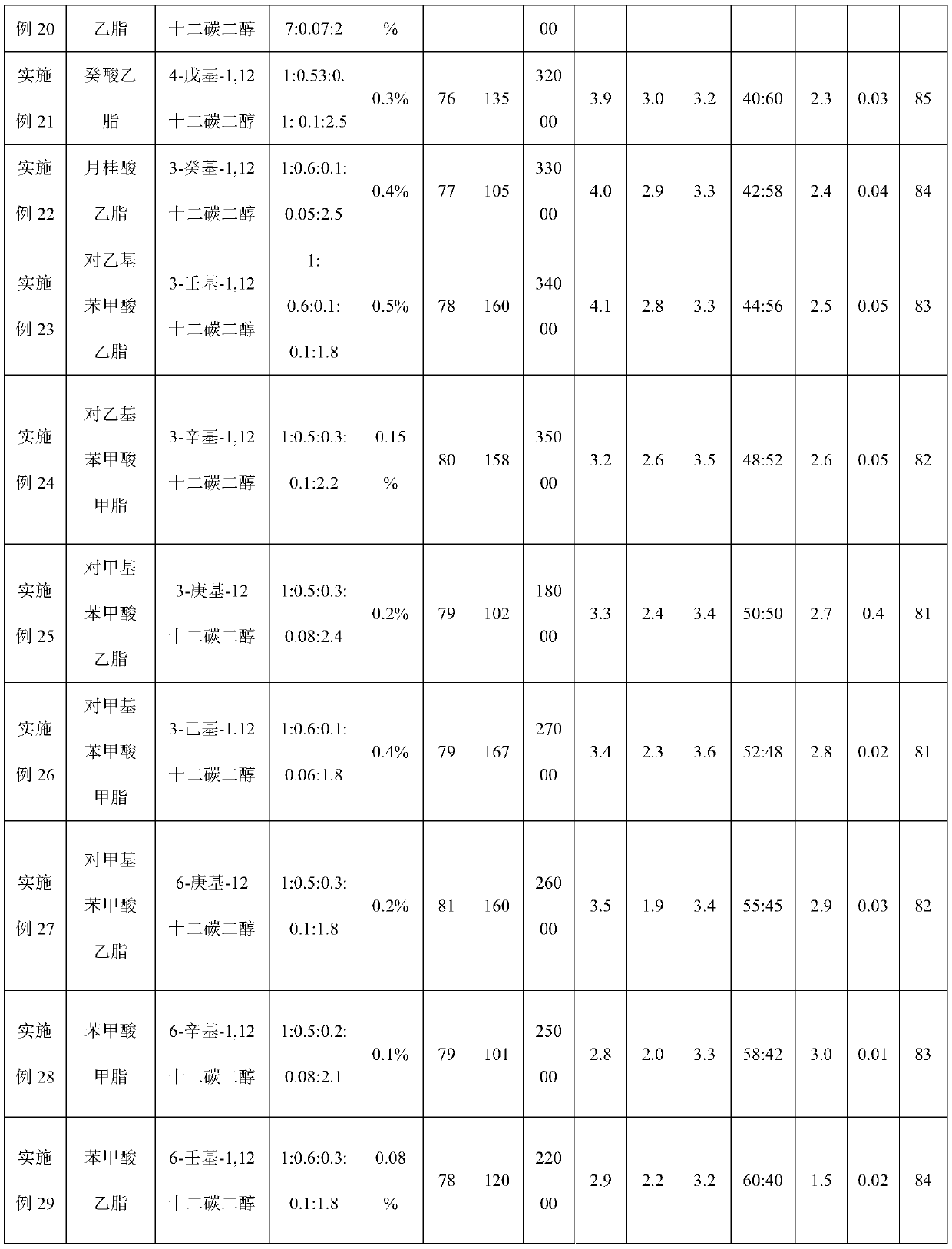

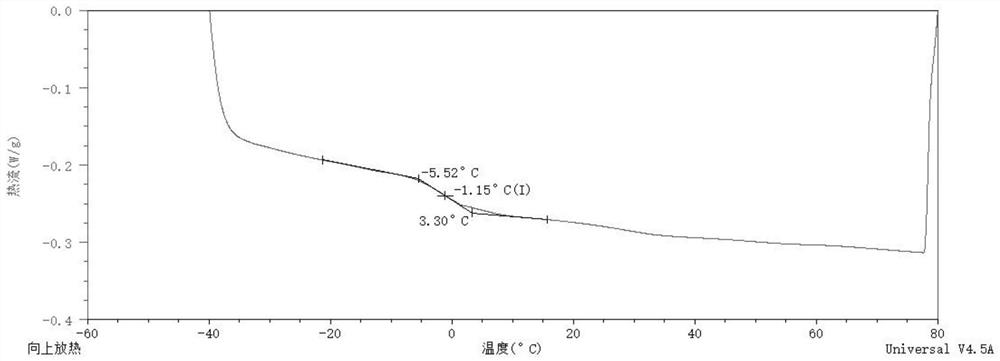

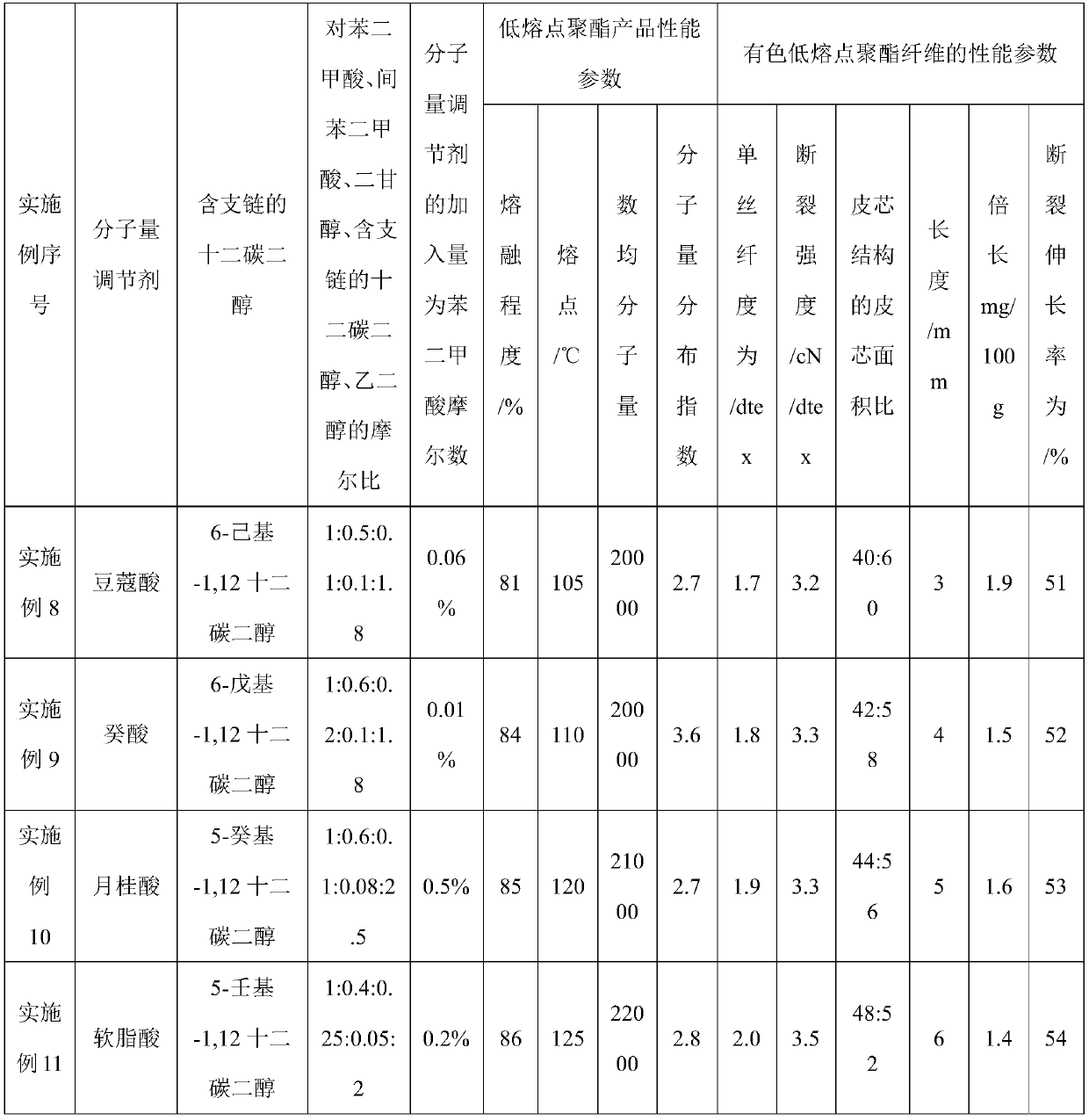

A kind of colored low melting point polyester fiber and its preparation method

ActiveCN106811828BIncrease vibrancyImprove sharpnessConjugated synthetic polymer artificial filamentsArtifical filament manufactureBenzoic acidCarbon number

The invention relates to colored low-melting-point polyester (PET) fiber and a preparation method thereof. The colored low-melting-point polyester fiber is of a skin-core structure, a skin layer is of low-melting-point polyester, and a core layer is of colored PET; the low-melting-point polyester is formed by a terephthalic acid chain segment, an isophthalic acid chain segment, a glycol chain segment, a diglycol chain segment, molecular weight modifier capping group and a branched-chain contained twelve carbon-dialcohol segments; a molecular weight modifier corresponding to the molecular weight modifier capping group specifically refers to benzoic acid, p-toluylic acid or ethylbenzoic acid, or methyl ester or ethyl ester corresponding to benzoic acid, p-toluylic acid or ethylbenzoic acid, or saturated fatty acid or methyl ester or ethyl ester corresponding to saturated fatty acid; the saturated fatty acid refers to the fatty acid 9-30 in carbon number; the preparation method includes the steps of low-melting-point polyester polymerization and skin-core composite spinning, drawing process is adopted in back spinning, and the low-melting-point polyester fiber is obtained via crimping, cutting and drying. The low-melting-point polyester fiber prepared is low in melting point and good in fresh image.

Owner:富威尔(珠海)复合材料有限公司

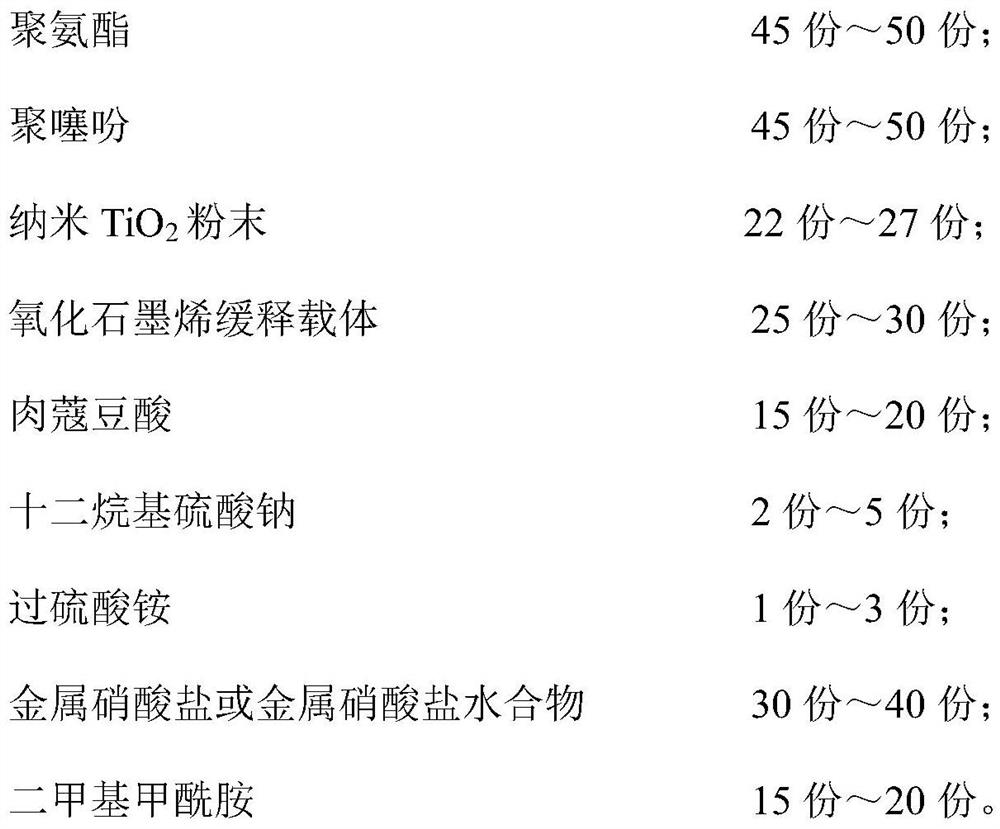

Water-based adhesive with low glass transition temperature as well as preparation method and application of water-based adhesive

PendingCN114525088AThe glass transition temperature has a large effectPlay an internal plasticizing roleMonocarboxylic acid ester polymer adhesivesPhotovoltaic energy generationSodium bicarbonatePolyvinyl alcohol

The invention relates to the technical field of functional material preparation, in particular to a water-based adhesive with low glass transition temperature as well as a preparation method and application thereof, and the water-based adhesive is prepared from the following raw materials in parts by weight: 310-335 parts of vinyl acetate; 120 to 165 parts of butyl acrylate; 4.0 to 5.5 parts of acrylic acid; 17 to 88 parts of polyvinyl alcohol, and 30 to 35 parts of polyvinyl alcohol; 25 to 27.5 parts of C12 to C14 secondary alcohol polyoxyethylene ether; 0.9 to 1.0 part of ammonium persulfate; 22 to 25 parts of triethyl citrate; 3.5 to 4.0 parts of sodium bicarbonate; and 675.9 to 801.4 parts of water. The defects that an existing water-based adhesive is high in glass-transition temperature and low in drying speed are overcome, the water-based adhesive high in drying speed is provided by reducing the glass-transition temperature of the water-based adhesive, and meanwhile the prepared water-based adhesive is small in particle size and has good viscosity, fluidity and stability.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A kind of ultra-short low melting point polyester fiber and preparation method thereof

ActiveCN106811827BAvoid bondingGood dispersionFibre typesFilament/thread formingPolyethylene terephthalateDiethylene glycol

The invention relates to an ultra-short polyester fiber with a low melting point and a method for preparing the ultra-short polyester fiber. The ultra-short polyester fiber with the low melting point is of a skin-core structure. Skin layers are made of polyester with a low melting point, and core layers are made of PET (polyethylene terephthalate); the polyester with the low melting point comprises terephthalic acid chain segments, isophthalic acid chain segments, ethylene glycol chain segments, diethylene glycol chain segments, molecular weight regulator chain segments and dodeca-carbon diol chain segments with branch chains; molecular weight regulators corresponding to the molecular weight regulator chain segments are particularly monoacid series or binary acid series. The method includes steps of polymerizing the polyester with the low melting point and carrying out skin-core composite spinning; carrying out back-spinning by the aid of drafting processes; carrying out oiling, cutting-off and drying to obtain the ultra-short polyester fiber with the low melting point. The ultra-short polyester fiber with the low melting point and the method have the advantages that the initial melting point of the ultra-short polyester fiber prepared by the aid of the method is reduced to a certain extent, the melting speed of the ultra-short polyester fiber is increased, the ultra-short polyester fiber can be immediately molten at the corresponding temperatures, and good melting effects can be realized.

Owner:扬州富威尔复合材料有限公司

A kind of long-chain alkyl ester modified novolac epoxy curing agent and preparation method thereof

Owner:HEFEI UNIV OF TECH

A kind of three-dimensional crimped low melting point polyester fiber and its preparation method

ActiveCN106811826BLow melting point temperatureFast meltingFilament/thread formingConjugated synthetic polymer artificial filamentsPolyethylene terephthalateDiethylene glycol

The invention relates to a three-dimensional crimp low-melting-point polyester fiber and a preparation method thereof. The three-dimensional crimp low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester, and a core layer is made of PET (polyethylene terephthalate). The low-melting-point polyester is formed by a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier and a branched dodecanediol chain segment. The molecular weight modifier is 1,8-naphthalic acid, phthalic acid, 1,2-cyclopentanedicarboxylic acid, 1,2-cyclohexanedicarboxylic acid or corresponding dimethyl esters or diethyl esters thereof. The preparation method includes steps of low-melting-point polyester polymerization, skin-core composite spinning, crimping, oiling, cutting and drying to obtain the three-dimensional crimp low-melting-point polyester fiber. Core layer spinneret holes of a spinneret plate in the composite spinning process are crescent. The three-dimensional crimp low-melting-point polyester fiber prepared according to the method is low in melting point.

Owner:扬州富威尔复合材料有限公司

A kind of low melting point polyester fiber and preparation method thereof

ActiveCN106757444BVolatileFully absorbedFilament/thread formingConjugated synthetic polymer artificial filamentsBenzoic acidPolyethylene terephthalate glycol

The invention relates to a polyester fiber with a low melting point and a method for preparing the polyester fiber. The polyester fiber with the low melting point is of a skin-core structure, skin layers are made of polyester with a low melting point, and core layers are made of PET (polyethylene terephthalate); the polyester with the low melting point comprises terephthalic acid chain segments, isophthalic acid chain segments, ethylene glycol chain segments, diethylene glycol chain segments and molecular weight regulator end-capping groups; corresponding molecular weight regulators of the molecular weight regulator end-capping groups particularly comprise benzoic acid, p-toluic acid or ethylbenzoic acid, or methyl ester or ethyl ester corresponding to the benzoic acid, the p-toluic acid or the ethylbenzoic acid, or saturated fatty acid or methyl ester or ethyl ester corresponding to the saturated fatty acid; the content of acetaldehyde in the polyester fiber with the low melting point is lower than 0.5 ppm. The method includes steps of polymerizing the polyester with the low melting point and carrying out composite spinning on skin and cores; carrying out back spinning by the aid of drafting-washing processes; carrying out oil-bath drafting by the aid of added sodium sulfite; carrying out crimping, cutting-off and drying to obtain the polyester fiber with the low melting point. The polyester fiber with the low melting point and the method have the advantages that the polyester fiber prepared by the aid of the method has the low melting point and is low in acetaldehyde content.

Owner:扬州富威尔复合材料有限公司

A kind of modified pvdc polymer and its preparation method and use

ActiveCN113061206BImprove machinabilityImprove mechanical propertiesTreatment using aerobic processesSustainable biological treatmentCellulosePolymer science

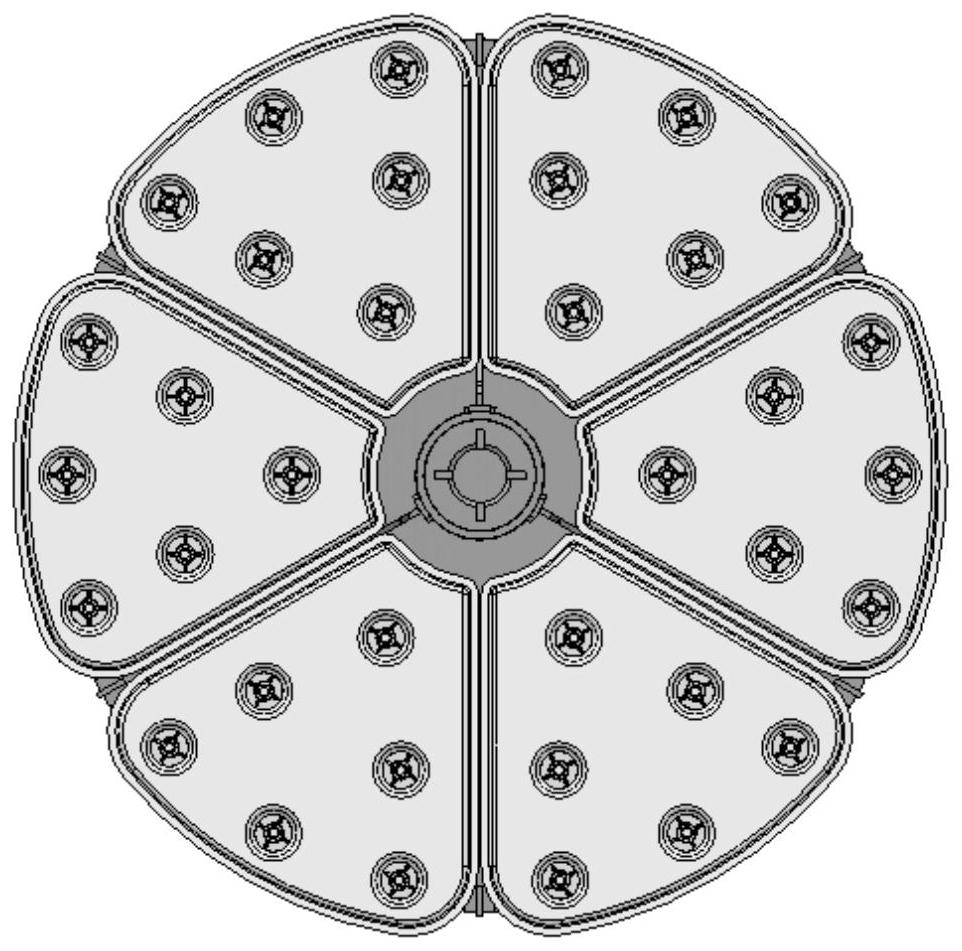

The present invention relates to a modified PVDC polymer. The modified PVDC polymer monomers include vinylidene chloride, vinylidene chloride, glycidyl methacrylate and cationic monomers. The modified PVDC polymer is prepared by suspending It is obtained by a polymerization method, and the dispersant used is a compound of water-soluble cellulose and polyvinylpyrrolidone. The molecular weight distribution of the prepared PVDC polymer is moderate, and the uneven distribution of the chain segments can play the role of internal plasticization. The biological turntable disc prepared by the invention is waterproof and corrosion-resistant, and can be used in wastewater treatment under wide pH conditions for a long time without disintegration, corrosion and other phenomena, and the mechanical strength is basically not decreased. The modified PVDC polymer of the present invention does not require an external plasticizer when preparing the biological turntable material, thereby avoiding thermal decomposition during processing caused by adding plasticizers; on the other hand, it also enhances the biological turntable disc in water. stability.

Owner:青海洁神环境科技股份有限公司

A kind of crystalline low melting point polyester fiber and its preparation method

ActiveCN106811829BImprove cohesive energyFast curingConjugated synthetic polymer artificial filamentsStretch-spinning methodsFiberPolymer science

The invention relates to a crystallinity low-melting point polyester fiber and a preparation method thereof; the crystallinity low-melting point polyester fiber is a belt core structure, wherein a belt layer is a low-melting-point polyester, and a core layer is PET; the low-melting point polyester fiber consists of terephthalic acid chain section, isophthalic acid chain section, 1, 3-propylene glycol chain section, dipropylene glycol chain section and molecular weight modifier, wherein the molecular weight modifier corresponding to the molecular weight modifier chain section is 1, 8-naphthalic acid, phthalic acid, 1, 2-cyclopentane dioctyl phthalate, 1, 2-cyclohexane dioctyl phthalate or corresponding dimethyl ester or diethyl ester. The preparation method includes low-melting-point polyester polymerization and belt core composite spinning, wherein post spinning adopts drafting-water washing technique, and drafting adopts oil bath drafting added with sodium sulfite; through rolling, cutting and drying, the crystallinity low-melting point polyester fiber is acquired. The crystallinity low-melting point polyester fiber prepared by the invention is low in melting point, and low in total content of acetaldehyde and acrolein.

Owner:扬州富威尔复合材料有限公司

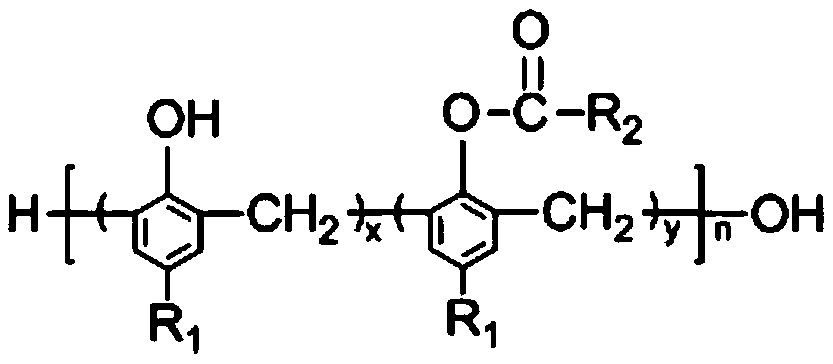

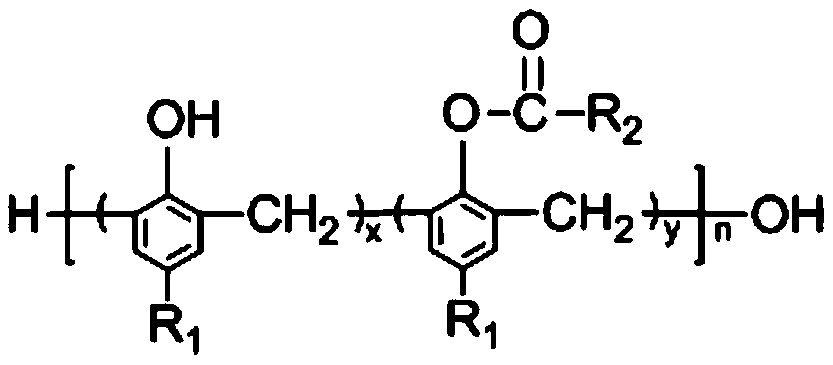

Long-chain alkyl ester modified linear phenolic epoxy curing agent and preparing method thereof

The invention relates to a long-chain alkyl ester modified linear phenolic epoxy curing agent and a preparing method thereof. The modified phenolic epoxy curing agent is prepared through substitutionreaction of linear phenolic resin and saturated fatty acid acyl chloride under action of an acid binding agent; the modified phenolic epoxy curing agent is one of ordinary linear phenolic resin and tert butylamine phenolic resin (the molecular weight is 500-1000); the saturated fatty acid acyl chloride is one of dodecyl acyl chloride to stearyl acyl chloride; a solvent is dichloromethane; the acidbinding agent is one of triethylamine and pyridine. The preparing method of the modified phenolic epoxy curing agent is the substitution reaction. The long-chain alkyl ester modified linear phenolicepoxy curing agent and the preparing method thereof have the advantages that the long-chain alkyl ester structure of the curing agent can lower the softening point of the linear phenolic epoxy resin and make the colloidal viscosity reduced due to the fact that introduction of long chains makes the free volume of a system increased and activity space of chain segments larger; meanwhile, the long-chain alkyl ester structure can have an internal plasticization effect and improve the processing fluidity of the epoxy resin.

Owner:HEFEI UNIV OF TECH

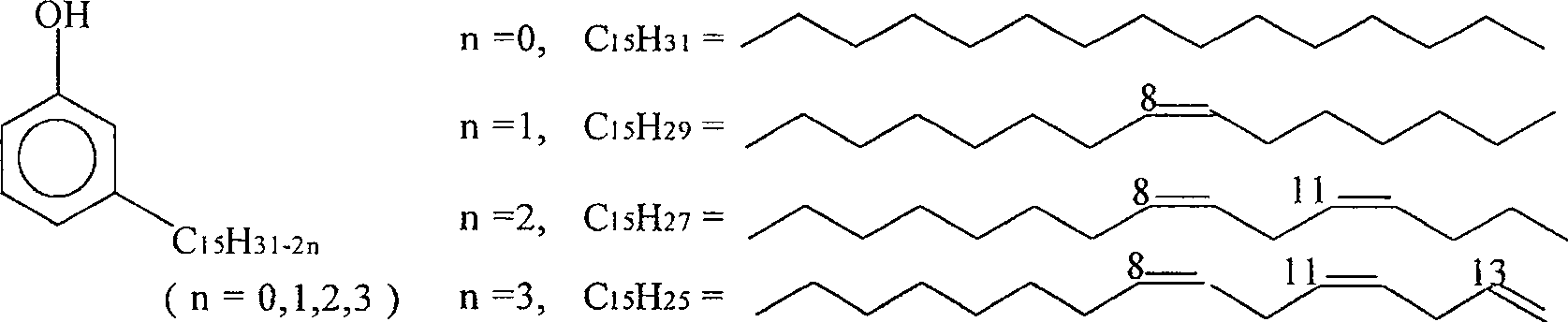

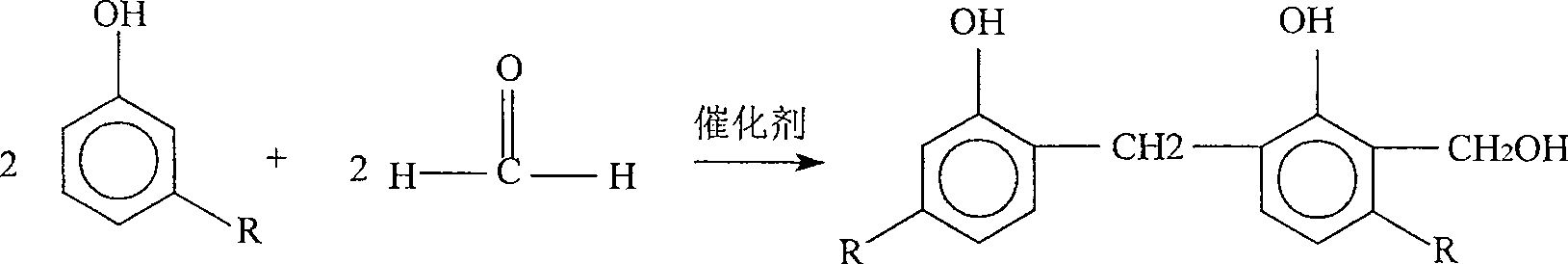

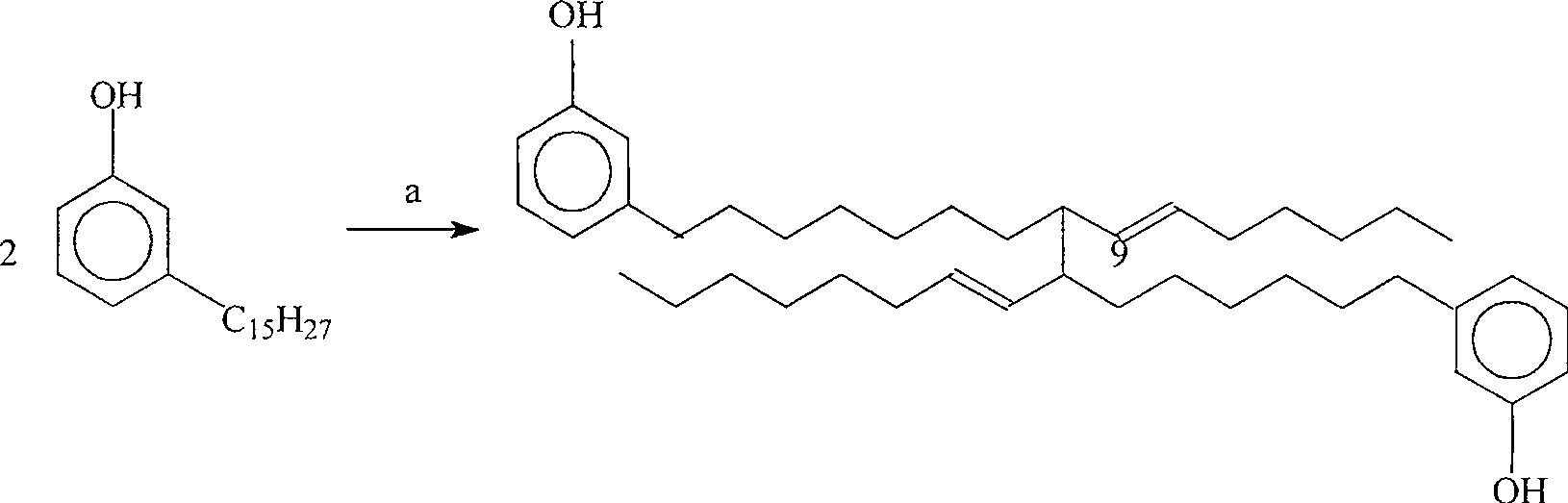

Preparation method of cashew nut oil modified alkyd resin

InactiveCN100519610CGood flexibilityPlay the role of internal plasticizationMetal layered productsSolventFORMALDEHYDE SOLUTION

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

A kind of filament low melting point polyester fiber and preparation method thereof

ActiveCN106757518BImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

Owner:扬州富威尔复合材料有限公司

Electromagnetic shielding coating for heat-shrinkable tube and preparation method thereof

ActiveCN104403480BImprove adhesionGood for adsorption and infiltrationElectrically-conductive paintsSilver platePolyamide

Owner:JINAN ZHONGZHENG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com