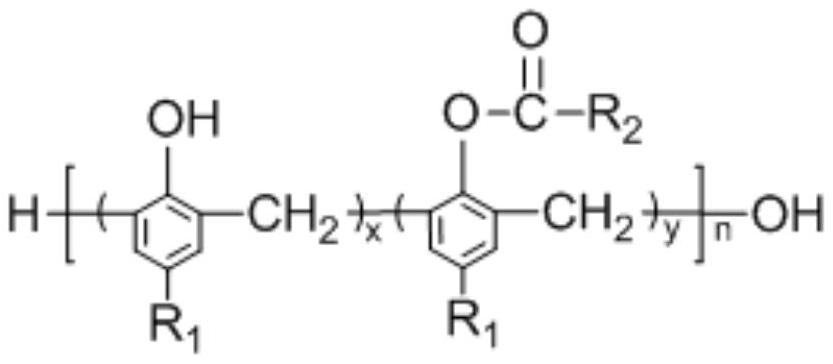

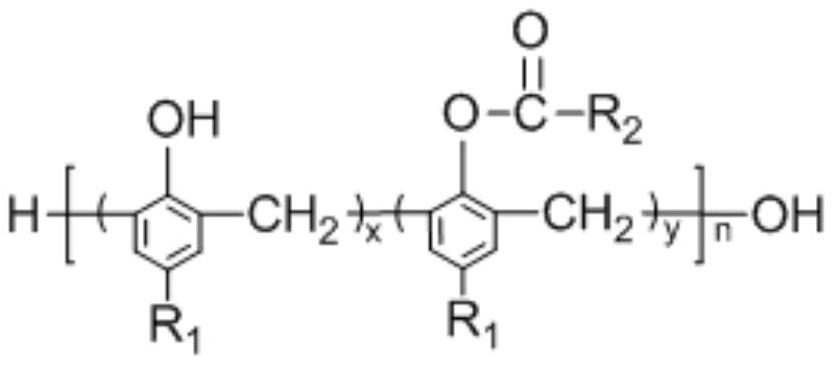

A kind of long-chain alkyl ester modified novolac epoxy curing agent and preparation method thereof

A long-chain alkyl ester, phenolic epoxy technology, applied to the field of in-line phenolic epoxy curing agent and its preparation, can solve the problems of poor compatibility, unfavorable processing and packaging molding, etc., and achieves reduced processing temperature and easy preparation. , The effect of product purification is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 200 ml of dichloromethane solvent dissolved in 40.525 g of linear tert-butyl resin (500 molecular weight), N 2 0.1 ml of acidic agent triethylamine was added under an atmosphere, stirred in an ice water bath for 10 min to give a phenolic resin-dichloromethane solution.

[0027] (2) The phenolic resin-dichloromethane solution was slowly added dropwise, and the slow drop acceleration was 2 seconds, and the reaction was continued for 3 h, and stirring was stirred at room temperature for 1.5 h, resulting in a long chain alkyl ester Sex phenolic resin-dichloromethane solution;

[0028] (3) Add 10 g of distilled water in a roll-alkyl ester-modified phenolic resin-dichloromethane solution to remove acidic agents, the liquid is obtained, and the dichloromethane is removed under reduced pressure, and the vacuum oven is dried 4H, grind, The linear phenolic epoxy curing agent of the long chain alkyl ester is obtained.

[0029] The seminated alkyl epoxy curing agent of the first em...

Embodiment 2

[0031] (1) 200 ml of dichloromethane solvent dissolved in 40.525 g of linear tert-butyl resin (500 molecular weight), N 2 0.1 ml of acidic agent triethylamine was added under an atmosphere, stirred in an ice water bath for 10 min to give a phenolic resin-dichloromethane solution.

[0032] (2) The phenolic resin-dichloromethane solution was slowly added dropwise, and the slow drop acceleration was 2 seconds, and the reaction was continued for 3.5 h, and the stirring was stirred at room temperature for 2 h, resulting in a long chain alkyl alkyl ester Sex phenolic resin-dichloromethane solution;

[0033] (3) Add 10 g of distilled water in a roll-alkyl ester-modified phenolic resin-dichloromethane solution to remove acidic agents, the liquid is obtained, and the dichloromethane is removed under reduced pressure, and the vacuum oven is dried 4H, grind, The linear phenolic epoxy curing agent of the long chain alkyl ester is obtained.

[0034] The softening temperature of the element-mod...

Embodiment 3

[0036] (1) 200 ml of dichloromethane solvent dissolved in 40.525 g of linear tert-butyl resin (500 molecular weight), N 2 0.1 ml of acidic agent triethylamine was added under an atmosphere, stirred in an ice water bath for 10 min to give a phenolic resin-dichloromethane solution.

[0037] (2) 2.423 g of octorate acid chloride was slowly added dropwise to the phenolic resin-dichloromethane solution, and the slow drop acceleration was 2 seconds, and the reaction was continued for 2.5 h, and stirred at room temperature for 1 h, resulting in a long chain alkyl ester Sex phenolic resin-dichloromethane solution;

[0038] (3) Add 10 g of distilled water in a roll-alkyl ester-modified phenolic resin-dichloromethane solution to remove acidic agents, the liquid is obtained, and the dichloromethane is removed under reduced pressure, and the vacuum oven is dried 4H, grind, The linear phenolic epoxy curing agent of the long chain alkyl ester is obtained.

[0039] The softening temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com