Polyester fiber with low melting point and method for preparing polyester fiber

A low-melting point polyester and fiber technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of limited application and achieve the effect of prolonging the residence time and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

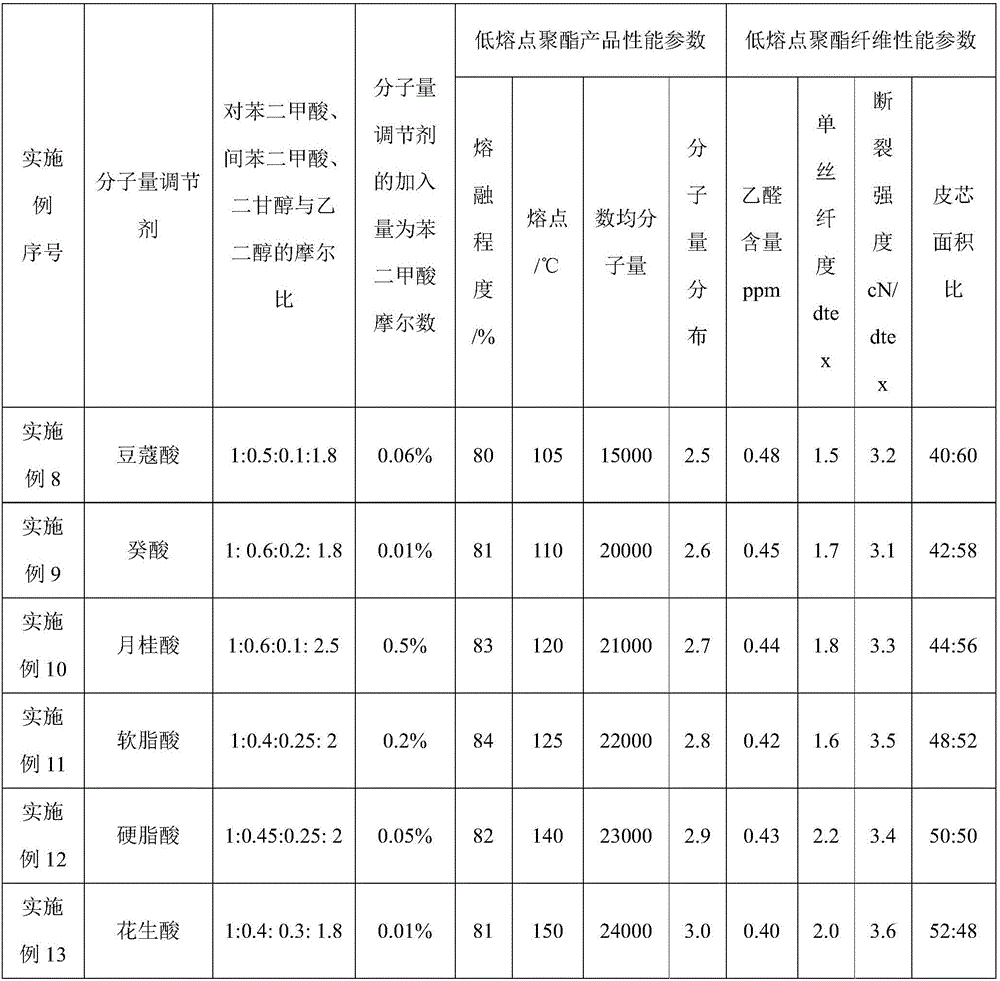

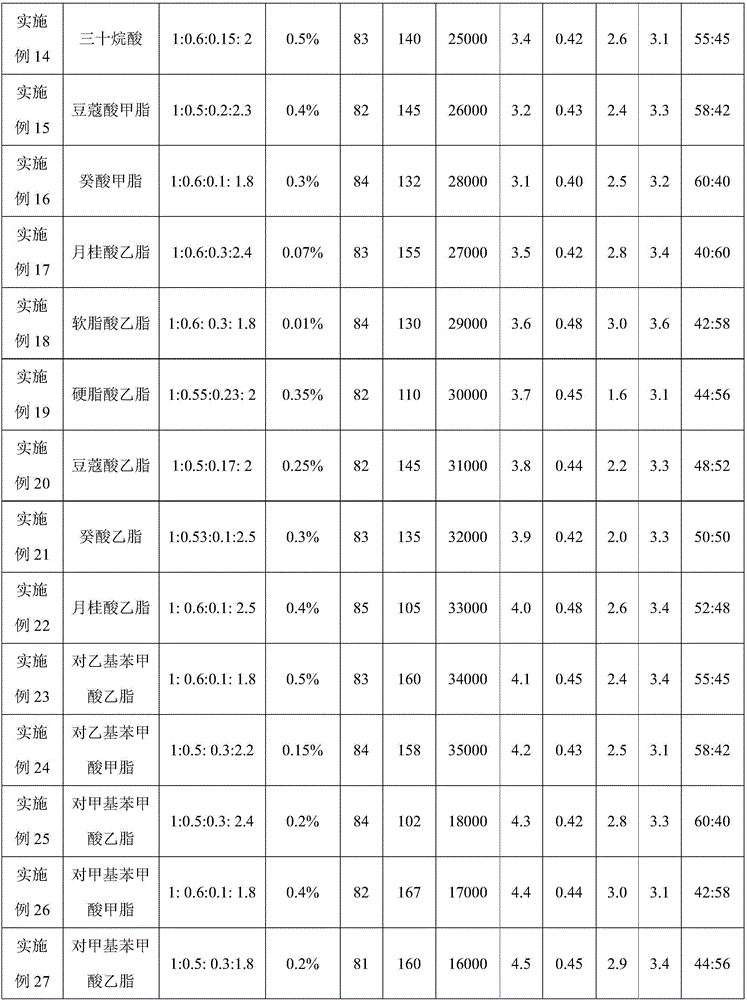

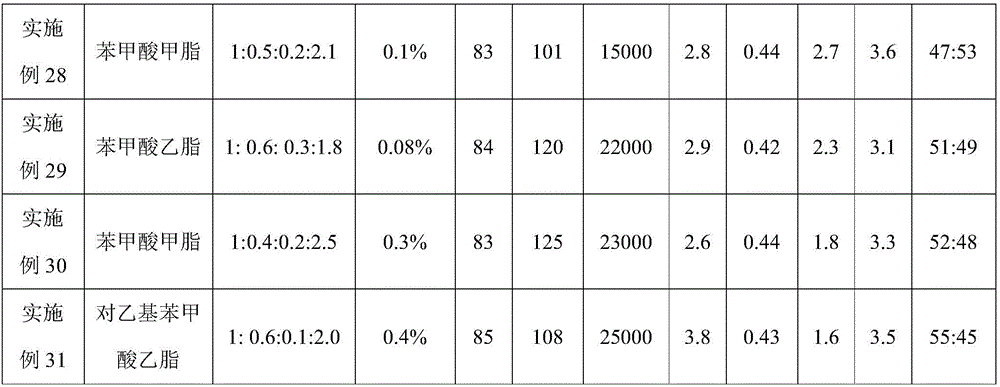

Examples

Embodiment 1

[0049] A kind of preparation method of low melting point polyester fiber:

[0050] a) low melting point polyester polymerization;

[0051] (1) Esterification reaction;

[0052] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, and benzoic acid into slurry, carry out esterification reaction, pressurized reaction under nitrogen atmosphere, pressurized pressure is normal pressure, temperature is 230 ℃, when the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; among them, terephthalic acid, isophthalic acid, diethylene glycol and ethylene glycol The molar ratio of alcohol is 1:0.4:0.1:1.8; the addition amount of benzoic acid is 0.01% of the molar number of phthalic acid.

[0053] (2) polycondensation reaction;

[0054] Then, under the action of catalyst and stabilizer, the polycondensation ...

Embodiment 2

[0065] A kind of preparation method of low melting point polyester fiber:

[0066] a) low melting point polyester polymerization;

[0067] (1) Esterification reaction;

[0068] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, and p-toluic acid into a slurry, carry out esterification reaction, and pressurize the reaction under nitrogen atmosphere, and the pressurized pressure is 0.3MPa. The temperature is 250°C, when the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; among them, terephthalic acid, isophthalic acid, diethylene glycol The molar ratio with ethylene glycol is 1:0.6:0.3:2.5; the amount of p-toluic acid added is 0.5% of the molar number of phthalic acid.

[0069] (2) polycondensation reaction;

[0070] Then, under the action of catalyst and stabilizer, the polycondensation ...

Embodiment 3

[0081] A kind of preparation method of low melting point polyester fiber:

[0082] a) low melting point polyester polymerization;

[0083] (1) Esterification reaction;

[0084]After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, and p-ethylbenzoic acid into a slurry, carry out esterification reaction, and pressurize the reaction under nitrogen atmosphere, and the pressurized pressure is 0.1MPa. The temperature is 240°C. When the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; among them, terephthalic acid, isophthalic acid, diethylene glycol The molar ratio with ethylene glycol is 1:0.5:0.2:2; the amount of p-ethylbenzoic acid added is 0.1% of the moles of phthalic acid.

[0085] (2) polycondensation reaction;

[0086] Then, under the action of catalyst and stabilizer, the polycondensatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com