Friction brake disk of double-speed electric-block and preparation method thereof

An electric hoist, friction braking technology, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems that restrict the popularization and application of electric hoist brake clutches, etc., and achieve large braking torque and high shear strength , The production process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below.

[0025] After in-depth research, the inventor used aramid fiber, chopped carbon fiber and mineral composite fiber materials as reinforcing fibers, hydrogenated nitrile rubber and melamine-cashew nut shell oil modified phenolic resin as binder, and medium carbon friction performance modifier The main formula system of the company, using one-time hot pressing forming technology, has developed a high-performance friction material used in the friction brake disc of the two-speed special-shaped electric hoist.

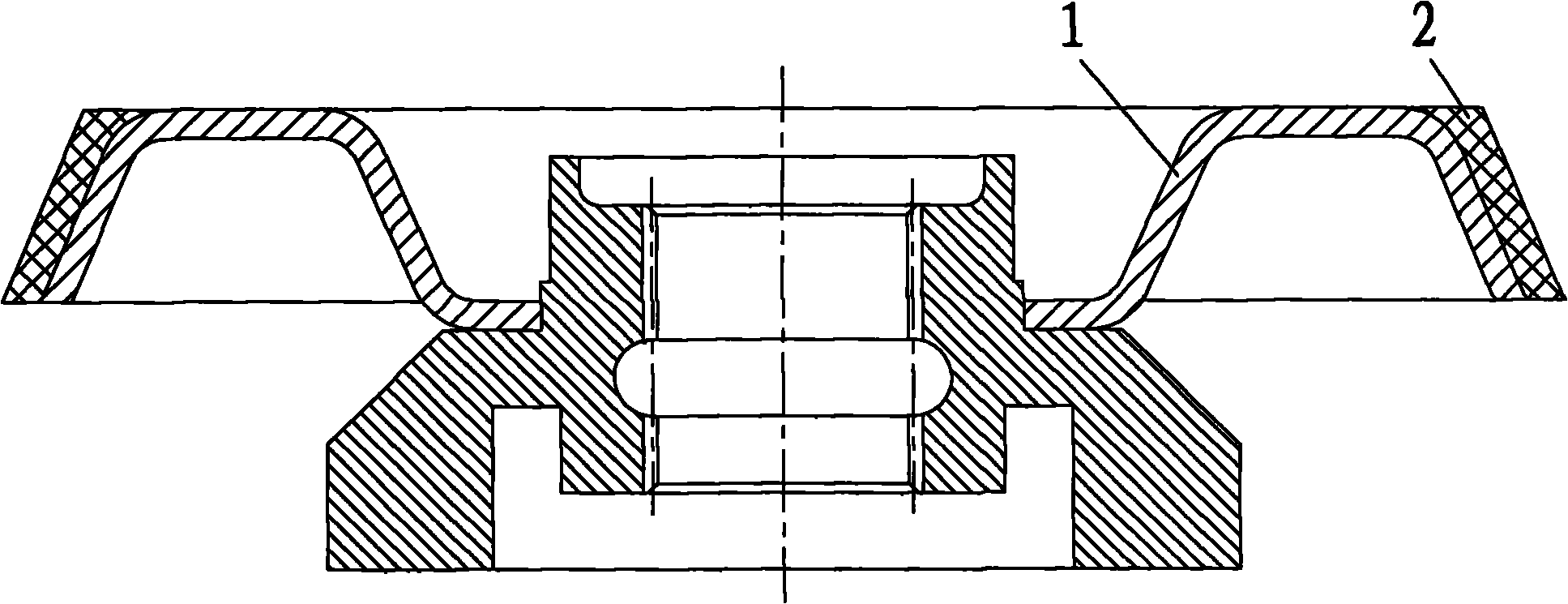

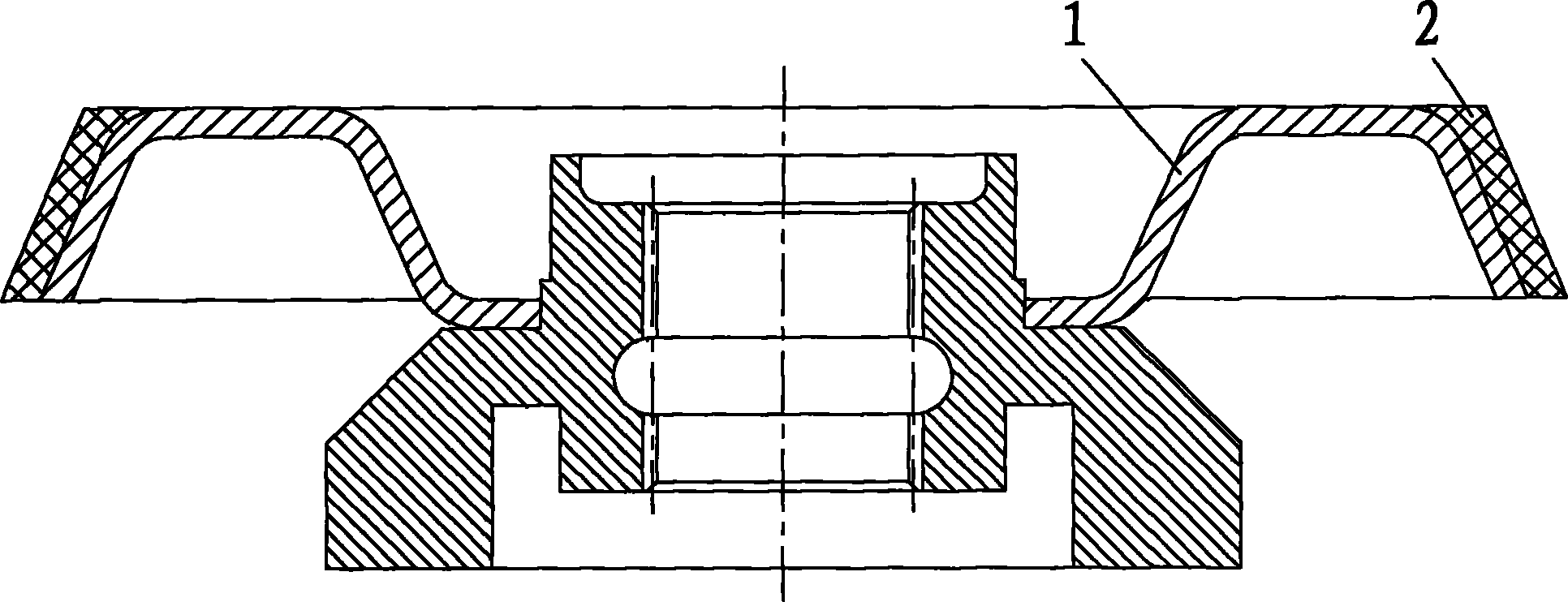

[0026] The two-speed electric hoist friction brake disc provided by the present invention includes an iron-based framework 1 and a friction material layer 2 bonded and fixed on the braking surface of the iron-based framework; the components and parts by weight contained in the friction material layer are:

[0027] 6-8 parts of modified phenolic resin, 2-3 parts of aramid fiber (preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com