3D printing precoated sand and preparation method thereof

A 3D printing, coated sand technology, applied in the field of coated sand, can solve the problems of inability to meet requirements, long cycle, low efficiency, etc., and achieve the effect of shortening product development cycle, low gas emission, and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

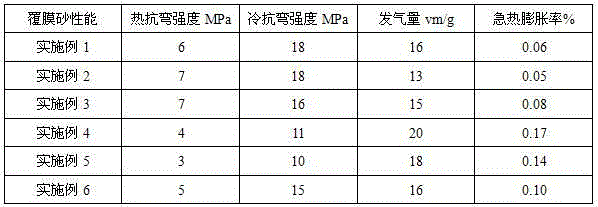

Examples

Embodiment 1

[0044] A 3D printing coated sand, comprising the following components:

[0045] Cashew nut shell 5wt %

[0046]Melamine formaldehyde resin 1wt %

[0047] Cashew nut shell liquid modified phenolic resin 1wt %

[0048] Hexatropine 0.6wt %

[0049] Lubricant 0.1 wt %

[0050] Sodium polyacrylate 0.1wt %

[0051] Aminosilane 0.1 wt %

[0052] Sodium lauryl sulfate 0.5 wt %

[0053] Raw sand balance;

[0054] According to the ratio of the above-mentioned 3D printing coated sand, make the following preparation, including the following steps:

[0055] (1) Wash the raw sand and cashew nut shells with water to remove the sediment, other sundries and crushed stones, then crush them, pass through a 110-130 mesh sieve, and grind until the particles are round;

[0056] (2) Preheat the raw sand and cashew nut shells treated above to 80-95°C, then add them to the sand mixer and mix them evenly;

[0057] (3) Add melamine formaldehyde resin, cashew nut shell liquid modified phenolic r...

Embodiment 2

[0060] A 3D printing coated sand, comprising the following components:

[0061] Cashew nut shell 6 wt %

[0062] Melamine formaldehyde resin 1.5 wt %

[0063] Cashew nut shell liquid modified phenolic resin 3 wt %

[0064] Hexatropine 0.7 wt %

[0065] Lubricant 0.2 wt %

[0066] Polyvinyl alcohol 0.2 wt %

[0067] Chlorate 0.3wt %

[0068] Borate 0.25 wt %

[0069] Methylpentanol 0.8 %

[0070] Raw sand balance;

[0071] According to the ratio of the above-mentioned 3D printing coated sand, make the following preparation, including the following steps:

[0072] (1) Wash the raw sand and cashew nut shells with water to remove the sediment, other sundries and crushed stones, then crush them, pass through a 110-130 mesh sieve, and grind until the particles are round;

[0073] (2) Preheat the raw sand and cashew nut shells treated above to 80-95°C, then add them to the sand mixer and mix them evenly;

[0074] (3) Add melamine formaldehyde resin, cashew nut shell liquid ...

Embodiment 3

[0077] A 3D printing coated sand, comprising the following components:

[0078] Cashew nut shell 8 wt %

[0079] Melamine formaldehyde resin 2 wt %

[0080] Cashew nut shell liquid modified phenolic resin 5 wt %

[0081] Hexatropine 0.8 wt %

[0082] Lubricant 0.4 wt %

[0083] Polyacrylamide 0.6wt %

[0084] Chlorate 0.2wt %

[0085] Polyethylene wax 0.4 wt %

[0086] Sodium tripolyphosphate 1 wt %

[0087] Raw sand balance;

[0088] According to the ratio of the above-mentioned 3D printing coated sand, make the following preparation, including the following steps:

[0089] (1) Wash the raw sand and cashew nut shells with water to remove the sediment, other sundries and crushed stones, then crush them, pass through a 110-130 mesh sieve, and grind until the particles are round;

[0090] (2) Preheat the raw sand and cashew nut shells treated above to 80-95°C, then add them to the sand mixer and mix them evenly;

[0091] (3) Add melamine formaldehyde resin, cashew nut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com