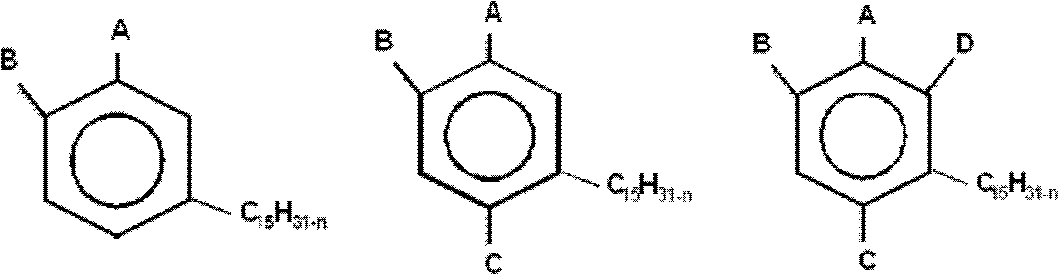

Cardanol polyether polyol and use thereof

A technology of cardanol polyether and polyol, applied in the field of polyether polyol, can solve problems such as refreshing records, and achieve the effects of good water resistance and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

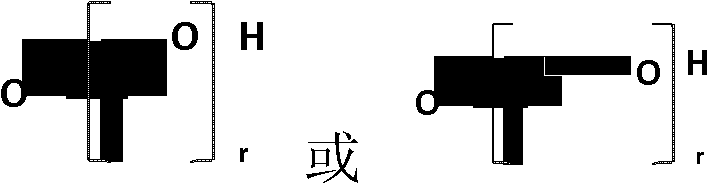

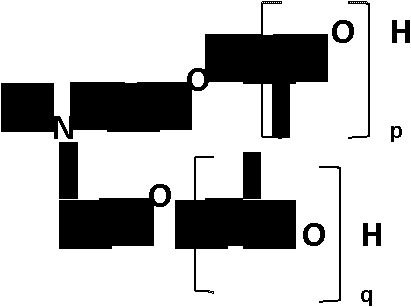

Method used

Image

Examples

Embodiment Construction

[0022] The properties of the polyether polyol of the present invention will be specifically described below in conjunction with the mass ratio of raw materials used in the synthesis process of the polyether polyol of the present invention.

[0023] Its synthesis process is:

[0024] 1. Add 50%-99% cardanol, 100-150 kg and 45-106 kg of diethanolamine or a mixture of diethanolamine and monoethanolamine to the heat preservation and pressurized reaction kettle, purging with nitrogen, sealing, heating and stirring until 85 -145°C.

[0025] 2. Add 10-30 kg of 55% (weight) formaldehyde solution dropwise into the reactor through a pressurized tank. The feeding speed is subject to the temperature of the reactor being controlled at 85-145°C. The entire feeding process takes 10-150 minutes , after the feeding is completed, continue to keep warm for half an hour to 3 hours, and the temperature is controlled at 120-145°C.

[0026] 3. Vacuum at 102-123°C, reduce the moisture to 0.30%-0.50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com